Content Menu

● Introduction

● What Is Powder Coating and Why Does It Matter?

>> Understanding the Process

>> Core Benefits for Manufacturers

● The Swinger Difference: Engineering Features That Matter

>> The Swinger Legacy

>> Innovative Spray Booth and Gun Configurations

>>> Optimized Gun Arrangement

>>> Advanced Powder Delivery

>>> Automatic Cleaning Cycles

>> Curing Ovens: Lower Energy, Consistent Results

>> Flexible Conveyor Systems

● Unmatched Reliability and Durability

>> Built for Demanding Environments

>> Uniform Coverage and Strong Adhesion

● User-Focused Design and Ease of Operation

>> Intuitive Controls and Automation

>> Quick Color Change Capability

>> Maintenance, Service, and Global Support

● Environmental and Safety Advantages

>> Low VOC, Sustainable Operations

>> Worker Safety Prioritized

● Global Track Record: Trusted Across Industries

>> Automotive and Transportation

>> Appliances and Consumer Goods

>> Construction and Heavy Industry

>> Electronics and Precision Engineering

● Continuous Innovation and Adaptability

>> Keeping Pace With Industry 4.0

>> Customizable and Modular Solutions

● Comparing Swinger to Traditional Systems

● Real-World Reliability: Testimonials and Case Studies

● Futureproof: Ready for Next-Generation Manufacturing

● Frequently Asked Questions and Answers

>> 1. What makes Swinger powder coating equipment more energy efficient than others?

>> 2. How does Swinger equipment ensure consistent coating quality for complex parts?

>> 3. Is maintenance and after-sale support readily available worldwide?

>> 4. How does Swinger equipment contribute to workplace safety?

>> 5. Can Swinger systems handle high-mix, low-volume production as well as mass manufacturing?

Introduction

The world of industrial finishing is in the midst of an evolution. Manufacturers demand not only robust and aesthetically pleasing finishes but also cost-effective, sustainable, and highly consistent solutions. Powder coating has emerged as a gold standard for durable surface protection, and among its innovators, Swinger powder coating equipment stands out as a favorite among global manufacturers. This article explores in-depth why Swinger systems have earned such widespread trust, detailing unique design features, reliability, global support, and value they bring to modern production environments.

What Is Powder Coating and Why Does It Matter?

Understanding the Process

Powder coating is a dry finishing technique where fine polyester or epoxy-based powders are applied electrostatically to a workpiece, then cured under heat to form a tough, uniform, and protective layer. This method is widely favored for its superior durability, environmental advantages, and versatility across industries such as automotive, electronics, construction, consumer goods, and heavy machinery.

Core Benefits for Manufacturers

- Superior durability: Powder coatings resist scratching, chipping, fading, and corrosion better than traditional liquid paints.

- Environmental safety: The process is nearly waste-free and emits little or no volatile organic compounds (VOCs).

- Cost efficiency: Powder overspray can be reclaimed and reused, shrinking operational costs.

The Swinger Difference: Engineering Features That Matter

The Swinger Legacy

Swinger powder coating equipment is renowned for its build quality, adaptability, and smart integration into advanced production lines. These systems leverage the latest developments in motion control, powder delivery, and energy management for optimal results.

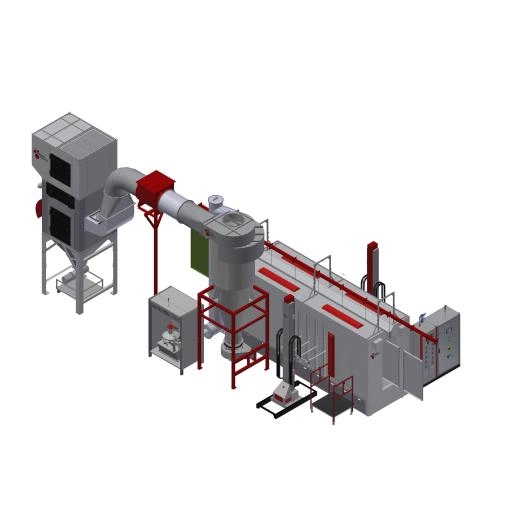

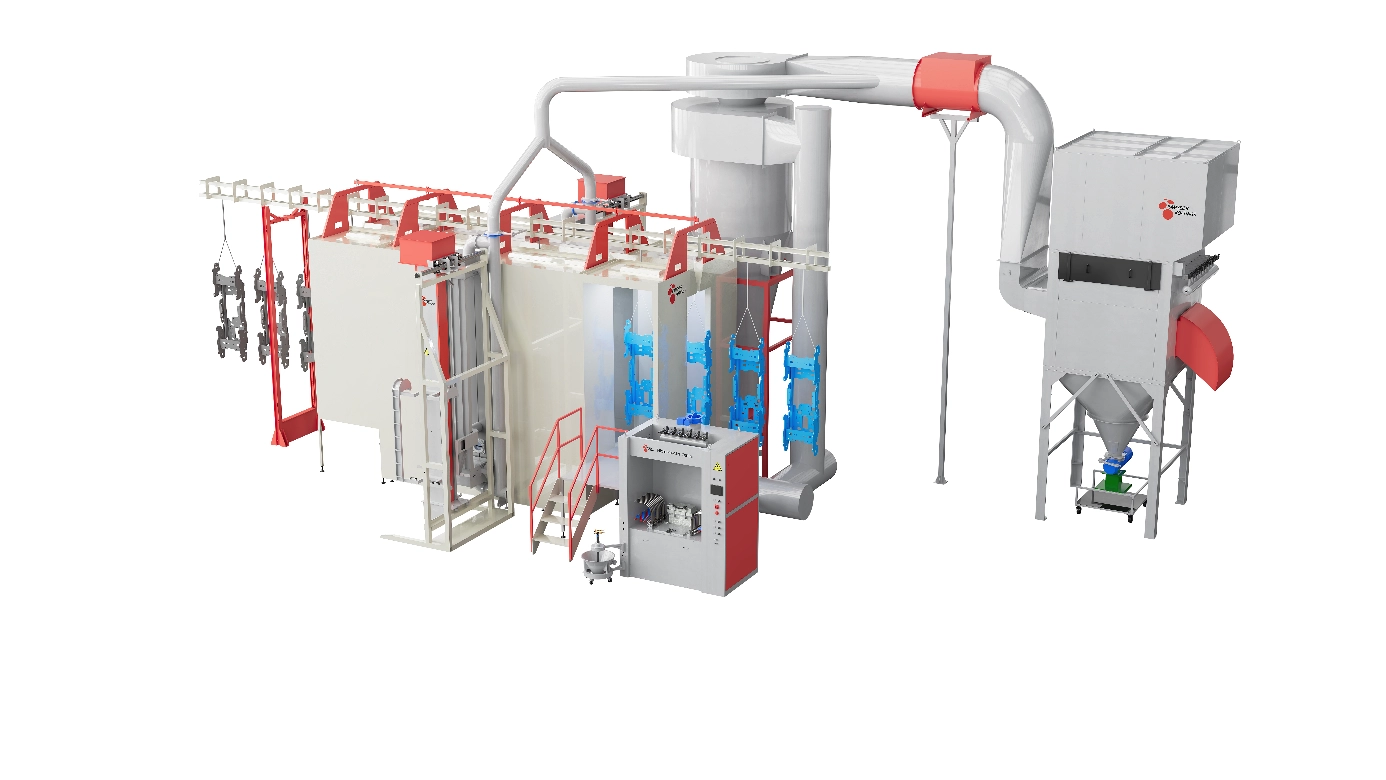

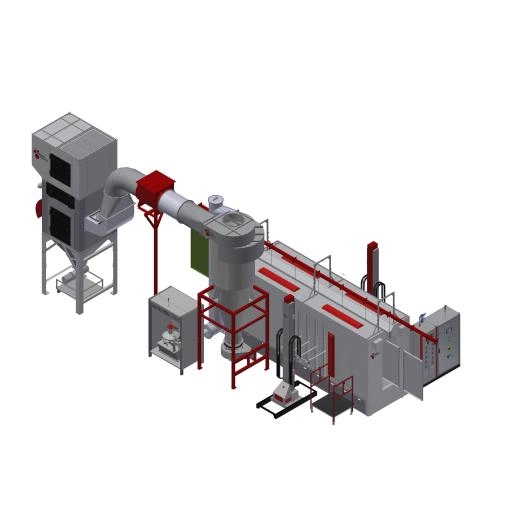

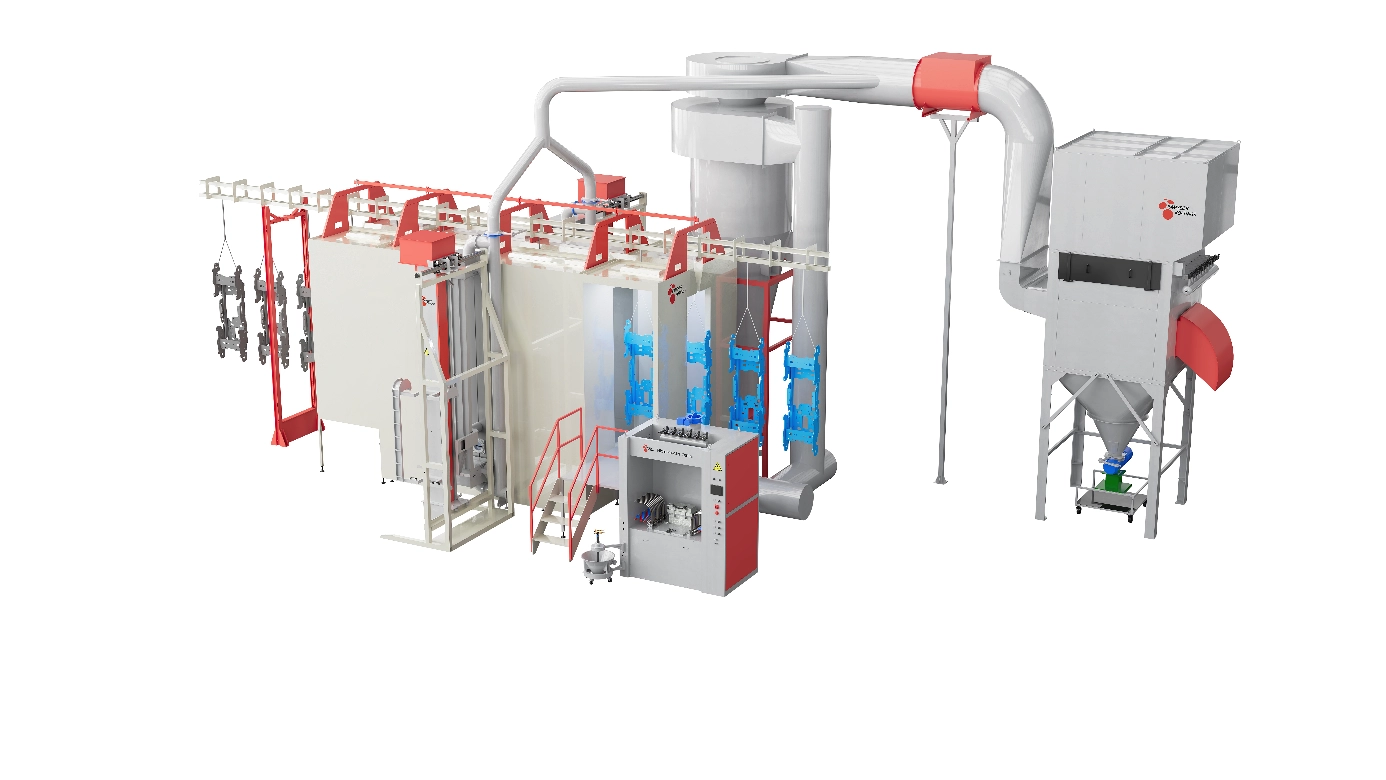

Innovative Spray Booth and Gun Configurations

Optimized Gun Arrangement

Swinger equipment uses precision gun spacing and positioning, ensuring complete and uniform coverage on even the most complex geometries. Motion controllers precisely manage swinging angles, spray cycles, and speeds.

Advanced Powder Delivery

The systems feature:

- Fluidized hoppers that keep powder particles in a “liquid-like” state for uniform distribution.

- Fine-tuned pumps and air controls for minimal waste and exact coverage.

Automatic Cleaning Cycles

To minimize downtime, Swinger booths are designed with self-cleaning options. Automated purging prevents color contamination and keeps system components in peak operating condition.

Curing Ovens: Lower Energy, Consistent Results

Swinger ovens use high-efficiency burners and advanced insulation. Their powders support lower curing temperatures, reducing energy consumption and greenhouse gas emissions. Precise control systems guarantee every batch meets stringent quality requirements.

Flexible Conveyor Systems

Swinger integrates intelligent conveyors for seamless part transfer, adjustable speeds, and alignment options—crucial for handling varying part shapes and sizes in high-volume facilities.

Unmatched Reliability and Durability

Built for Demanding Environments

Global manufacturers, from automotive plants in Germany to appliance factories in China, select Swinger powder coating equipment to meet high throughput demands. Rugged frames, corrosion-resistant materials, and industrial-grade electronics ensure long, trouble-free life even under continuous use.

Uniform Coverage and Strong Adhesion

Swinger's proprietary gun technology achieves excellent powder adhesion, reducing rejects and minimizing costly rework. Well-controlled application ensures every edge and recess is coated evenly, a critical factor for industries where corrosion protection and finish quality cannot be compromised.

User-Focused Design and Ease of Operation

Intuitive Controls and Automation

Operators benefit from user-friendly interfaces, electronic parameter adjustment, and programmable recipes for different products. Automated diagnostics and closed-loop feedback reduce human error and streamline start-up or changeover procedures.

Quick Color Change Capability

For manufacturers who switch frequently between product lines, Swinger systems support fast, tool-less color changes. This minimizes production downtime and boosts operational flexibility.

Maintenance, Service, and Global Support

Swinger maintains a worldwide service and distributor network, ensuring rapid support, spare parts supply, and professional guidance before and after installation. Test centers allow clients to trial equipment and tailor solutions for specific applications prior to purchase.

Environmental and Safety Advantages

Low VOC, Sustainable Operations

Powder coating inherently produces less environmental pollution than liquid paint finishing. Swinger equipment further supports sustainability through:

- Minimal powder wastage.

- Fully enclosed booths that capture overspray.

- Low curing temperatures, which reduce energy use and emissions.

Worker Safety Prioritized

Equipment is designed with extensive safety mechanisms, such as:

- Enclosed, vented booths to prevent powder inhalation.

- Automatic shutdowns in abnormal conditions.

- Ergonomic layouts that minimize repetitive strain for operators.

Global Track Record: Trusted Across Industries

Automotive and Transportation

Automotive manufacturers rely on Swinger for body panels, chassis parts, and wheel coatings. Uniform coverage, rapid color change, and durability are prized in environments with massive volume and stringent standards.

Appliances and Consumer Goods

Major appliance manufacturers favor Swinger for its consistency, attractive finishes, and the ability to offer customers a wide palette of colors with rapid turnaround.

Construction and Heavy Industry

Corrosion resistance is paramount in construction and infrastructure. Swinger's robust coatings protect metal beams, railings, and outdoor structural components in harsh climates.

Electronics and Precision Engineering

Because Swinger delivers exceptionally uniform, thin finishes without outgassing or orange-peel effects, electronics makers use their equipment for casings, racks, and sensitive assemblies.

Continuous Innovation and Adaptability

Keeping Pace With Industry 4.0

Swinger continually evolves product lines to integrate with Industry 4.0 practices:

- Digital monitoring of coating variables.

- Cloud-based diagnostics and predictive maintenance.

- Seamless interface with automated material handling systems.

Customizable and Modular Solutions

Manufacturers can specify Swinger equipment to match their unique requirements, from compact lab-scale units for R&D to fully automated lines for mass production.

Comparing Swinger to Traditional Systems

| Feature | Swinger Systems | Traditional Systems |

| Energy Efficiency | Lower curing temps, better heat retention | Higher energy consumption |

| Automation | Programmable, modular automation | Often manual or semi-automatic |

| Color Change Speed | Rapid, minimal contamination | Slower, greater risk of cross-color |

| Maintenance Service | Global network, responsive | Varies, often localized support |

| Environmental Impact | Eco-friendly, low VOCs, recyclability | More waste, possible VOC emissions |

| Application Quality | Superior edge/recess coverage | Inconsistent coverage on challenges |

Real-World Reliability: Testimonials and Case Studies

Leading manufacturers consistently choose Swinger systems for long-term operational reliability and measurable ROI. Field reports reveal:

- Significant reductions in rejects and rework due to precise, even coatings.

- Lower operational costs from energy, labor, and powder reuse efficiencies.

- Rapid recovery from downtime, thanks to global customer support and robust spare parts logistics.

- Compliance with tightening environmental and workplace safety standards worldwide.

Futureproof: Ready for Next-Generation Manufacturing

As global manufacturers move toward sustainability, digitalization, and ultra-efficient production, equipment must adapt. Swinger's flexibility, proven performance, and integration readiness ensure it remains a platform of choice for forward-looking companies.

Frequently Asked Questions and Answers

1. What makes Swinger powder coating equipment more energy efficient than others?

Swinger systems operate with specially formulated powders that cure at lower temperatures, leading to reduced energy usage. Their high-efficiency ovens and advanced insulation further minimize heat loss, which is particularly attractive for manufacturers seeking greener operations.

2. How does Swinger equipment ensure consistent coating quality for complex parts?

Swinger integrates precision motion controllers, optimized spray gun configurations, and fluidized hoppers for uniform powder distribution. This combination guarantees even coverage, minimizes rejects, and eliminates typical finish defects, even on intricate or irregular surfaces.

3. Is maintenance and after-sale support readily available worldwide?

Yes, Swinger has established a global network of service centers and distributors, providing prompt maintenance support, spare parts, and technical advice before and after installation to maximize uptime and performance.

4. How does Swinger equipment contribute to workplace safety?

Swinger designs all equipment with operator safety in mind: features include enclosed, ventilated booths, automatic emergency shutdowns, and ergonomic layouts. These lower the risk of accidents and minimize powder exposure.

5. Can Swinger systems handle high-mix, low-volume production as well as mass manufacturing?

Absolutely. From flexible batch lines to fully automated continuous production, Swinger powder coating systems can be tailored to match both small, custom jobs and the highest-volume industrial environments. Fast color change and recipe management features make them ideal for dynamic production flows.

[1] https://www.oemoven.com/powder

[2] https://www.funkymonkeybars.com/blogs/news/why-funky-monkey-bars-uses-in-house-dulux-powder-coating

[3] https://www.altaracks.com/swinger-w-short-hitch/

[4] https://bfsales.com/powder-coating-equipment-101/

[5] https://www.ametals.com/post/everything-you-should-know-about-powder-coating-finishes

[6] https://www.snsinsider.com/reports/powder-coating-equipment-market-6045

[7] https://www.powdercoatguide.com/2012/11/getting-into-powder-coating-equipment.html

[8] https://cwfinishing.net/science-powder-coating-plastic/

[9] https://www.grandviewresearch.com/industry-analysis/powder-coatings-equipment-market

[10] https://www.youtube.com/watch?v=cNX3XjoTvCI

[11] https://www.swisherinc.com/powder-coating

[12] https://www.archivemarketresearch.com/reports/powder-coating-equipment-496664

[13] https://boneheadperformance.com/powder-coating/atv-and-motorcycle-powder-coating-prices/

[14] https://www.ramseierkoatings.com/what-makes-swinger-powder-coating-systems-stand-out-in-the-market.html

[15] https://www.marketsandmarkets.com/Market-Reports/powder-coating-equipment-market-189728086.html

[16] https://www.ramseierkoatings.com/how-to-choose-the-right-swinger-powder-coating-system-for-your-production-line.html

[17] https://www.powdercoatedtough.com/News/ID/208/Dont-Blame-the-Powder

[18] https://www.prnewswire.com/news-releases/global-industry-analysts-predicts-the-world-powder-coating-equipment-market-to-reach-3-billion-by-2026-301376659.html

[19] https://www.ramseierkoatings.com/best-swinger-powder-coating-machines-for-high-performance-finishing.html

[20] https://www.ramseierkoatings.com/swinger-vs-traditional-powder-coating-systems-which-one-fits-your-needs.html

[21] https://www.youtube.com/watch?v=UhtdWpK-XaE

[22] https://gat-systems.com/powder-coating-equipment-checklist-12-must-have-components-for-a-flawless-finish/

[23] https://www.tiger-coatings.com/us-en/tiger-group/tiger-blog/tigers-laboratory-testing-for-powder-coating

[24] https://www.wagner-group.com/us/industry/products/powder-coating/complete-systems/

[25] https://k9-kennelstore.com/and-the-rest/kennel-care-maintenance.html

[26] https://www.tiger-coatings.com/us-en/blog/powder-coating-process

[27] https://adventureplaysystems.com/powder-coating/

[28] https://www.ramseierkoatings.com/news/Swinger-Powder-Coating-System-Setup-and-Maintenance-Tips.html

[29] https://accent-lighting.mybigcommerce.com/real-simple-one-light-wall-swinger-165-1806/

[30] https://www.lanecoatings.com/powder-coating-care-maintenance/

[31] https://www.altaracks.com/swinger-step-gpp/

[32] https://www.pinterest.com/pin/824158800593266813/

[33] https://totalfinishingsupplies.com/collections/powder-coating

[34] https://www.atlas-mts.com/-/media/ametekatlas/files/knowledgecenter/sunspots/volume-issue/2012-02_atlas_sunspots_v0142issue92.pdf

[35] https://www.lowes.com/pl/Removable-ash-catcher-Side-table-swinger--Grills-Grills-outdoor-cooking-Outdoors/4294610392

[36] https://www.youtube.com/watch?v=avmfNPCuNbU

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.