Content Menu

● What Is an Automatic Electrostatic Spray Gun?

>> How Does Electrostatic Spraying Work?

>> Automatic Versus Manual Electrostatic Spray Guns

● Advantages of Automatic Electrostatic Spray Guns

>> Enhanced Material Efficiency

>> Superior Coating Quality

>> Reduced Environmental Impact

>> Cost Savings Over Time

>> Increased Production Speed and Automation

● Industries Benefiting from Automatic Electrostatic Spray Guns

>> Automotive Manufacturing

>> Electronics and Appliances

>> Furniture and Woodworking

>> Aerospace and Defense

● Technical Considerations When Switching to Automatic Electrostatic Spray Guns

>> Compatibility with Coating Materials

>> Equipment Maintenance and Training

>> System Integration and Layout

>> Safety Precautions

● Steps for a Successful Transition to Automatic Electrostatic Spraying

>> Conducting a Needs Assessment

>> Pilot Testing

>> Partnering with Experienced Suppliers

>> Training and Change Management

>> Continuous Monitoring and Improvement

● Frequently Asked Questions About Automatic Electrostatic Spray Guns

In the ever-evolving manufacturing world, companies constantly seek ways to improve efficiency, product quality, and sustainability. One technology rapidly gaining traction is the automatic electrostatic spray gun. This innovative spraying technology offers numerous advantages over traditional spraying methods, which explains why many manufacturers are making the switch. This article delves into the reasons behind this shift, the technology's benefits, and key applications across industries.

What Is an Automatic Electrostatic Spray Gun?

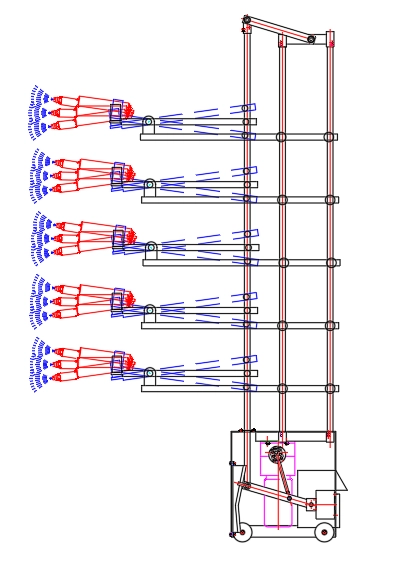

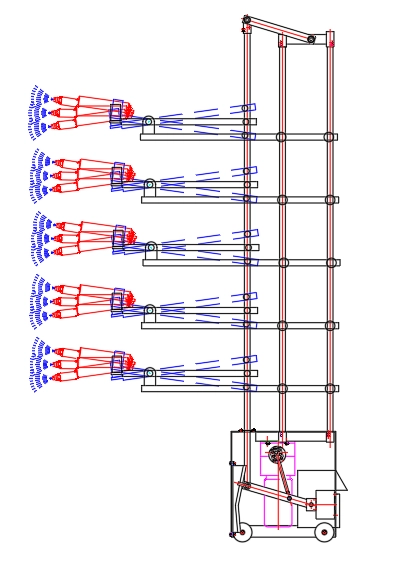

Automatic electrostatic spray guns are advanced coating devices that use electrostatic forces to apply paint or other finishing materials uniformly to surfaces. The gun charges the paint particles electrically, which are then attracted to the oppositely charged target object. This method increases material transfer efficiency, ensuring more even coverage and less waste.

How Does Electrostatic Spraying Work?

Electrostatic spraying relies on the principle of opposite charges attracting. The paint droplets receive a positive or negative charge inside the spray gun, while the object being coated holds the opposite charge or is grounded. This electrostatic interaction directs paint droplets onto the surface with increased precision, producing a uniform film and minimizing overspray.

Automatic Versus Manual Electrostatic Spray Guns

Unlike manual electrostatic guns requiring human operation, automatic electrostatic spray guns are integrated into robotic or automated production lines. These systems enable consistent, repeatable spray patterns, improving batch-to-batch quality and reducing labor costs.

Advantages of Automatic Electrostatic Spray Guns

The clear advantages of automatic electrostatic spray guns explain their rising popularity among manufacturers globally. These benefits include:

Enhanced Material Efficiency

One of the biggest benefits is improved paint transfer efficiency. Traditional spray guns typically waste a large percentage of coating material due to overspray and bounce-back. The electrostatic attraction in automatic guns reduces this waste drastically because paint droplets are pulled toward the target, leading to transfer efficiencies of up to 90% or more.

Superior Coating Quality

The electrostatic charge helps paint particles wrap around surfaces, even complex contours and recessed areas, ensuring an even, smooth finish. This results in higher-quality coatings with fewer runs, sags, or thin spots—critical for aesthetic and protective purposes.

Reduced Environmental Impact

Lower paint waste means fewer volatile organic compounds (VOCs) released into the air, making electrostatic spray technologies more environmentally friendly. Furthermore, many automatic systems support waterborne paints, which have lower environmental impact compared to solvent-based alternatives.

Cost Savings Over Time

Although initial setup costs for automatic electrostatic spray gun systems can be higher than traditional methods, the long-term savings on paint materials, waste disposal, labor, and rework can be substantial. These cumulative cost efficiencies contribute significantly to manufacturers switching to automatic electrostatic spraying.

Increased Production Speed and Automation

Automatic spray guns integrated with robotic systems enhance throughput by enabling high-speed, consistent application. This automation reduces dependence on operator skill and fatigue, enabling continuous production runs with uniform results.

Industries Benefiting from Automatic Electrostatic Spray Guns

Several industries are leading the adoption of automatic electrostatic spray guns due to the specific challenges they face around coating quality, efficiency, and environmental regulations.

Automotive Manufacturing

In automotive painting, appearance and durability are paramount. Automatic electrostatic spray guns lend themselves well to the complex shapes and precision required for vehicle bodies and components. Many car manufacturers use this technology to maximize coating efficiency, reduce paint waste, and achieve consistent color matching.

Electronics and Appliances

The electronics and home appliance industry requires smooth, uniform coatings for both aesthetic and functional purposes such as corrosion resistance. Automatic electrostatic spray systems ensure tightly controlled film thicknesses on intricate parts like metal frames, panels, and casings.

Furniture and Woodworking

Wood furniture manufacturers increasingly use automatic electrostatic guns for applying sealants, stains, and paints evenly. The technology's ability to handle different viscosities and wrap coatings around irregular wood designs improves productivity and finish quality.

Aerospace and Defense

The aerospace industry demands high standards for protective coatings on aircraft parts, requiring a finish that resists harsh environmental conditions. Automatic electrostatic spray guns deliver uniform coatings with high transfer efficiency, reducing material waste and improving part lifespan.

Technical Considerations When Switching to Automatic Electrostatic Spray Guns

Manufacturers thinking of adopting automatic electrostatic spray guns should evaluate technical details carefully to ensure optimal system selection and integration.

Compatibility with Coating Materials

Not all coating materials perform optimally with electrostatic charging. Checking compatibility with existing paints, primers, or sealants is essential. Many suppliers also offer products designed specifically for electrostatic applications to maximize results.

Equipment Maintenance and Training

Although automation reduces operator labor, maintenance of electrostatic equipment requires specialized knowledge. Routinely cleaning the gun and monitoring system parameters is critical for maintaining spray quality. Training maintenance staff beforehand can reduce downtime.

System Integration and Layout

Since automatic guns are typically integrated into automated production lines, manufacturers must plan system layout to accommodate robot arms, conveyors, and other peripherals. A well-designed setup minimizes bottlenecks and maximizes spray reach.

Safety Precautions

Electrostatic spray guns generate high voltage fields, which can pose electrical hazards if mishandled. Proper grounding and safety protocols must be strictly followed, and the working environment kept free from flammable vapors or dust.

Steps for a Successful Transition to Automatic Electrostatic Spraying

Switching to automatic electrostatic spray technology involves careful planning and gradual implementation for maximum benefit.

Conducting a Needs Assessment

Identify the key challenges faced with current spraying processes, including material waste, coating consistency, labor costs, and environmental compliance. Understanding current pain points aids in defining success criteria.

Pilot Testing

Start with a pilot line or trial integration to evaluate how the automatic electrostatic spray works with your specific products and production speed. This approach allows for troubleshooting and optimization before full deployment.

Partnering with Experienced Suppliers

Collaborate with reputable electrostatic spray system providers who offer technical support and training. Experienced partners can help tailor solutions to your product requirements and production line conditions.

Training and Change Management

Ensure that production and maintenance teams receive comprehensive training on system operation, safety, and troubleshooting. Legitimize the benefits of automation to secure workforce buy-in.

Continuous Monitoring and Improvement

Post-implementation monitoring is crucial to detect issues, track material savings, and verify coating quality improvements. Use data analytics and feedback loops to refine settings and maximize ROI.

Frequently Asked Questions About Automatic Electrostatic Spray Guns

Q1: What types of coatings can be used with automatic electrostatic spray guns?

A1: Electrostatic spray guns are compatible with a wide range of coatings, including solvent-based paints, waterborne paints, powder coatings, primers, sealants, and stains, provided they have the right electrical conductivity and viscosity.

Q2: Are automatic electrostatic spray guns more expensive than traditional spray guns?

A2: The upfront cost is generally higher due to automation and advanced technology, but savings in paint usage, labor, and waste disposal often offset the initial investment over time.

Q3: Can automatic electrostatic spray guns be integrated into existing production lines?

A3: Yes, most systems are designed for integration with robotic arms or conveyor systems, but careful planning and adjustments may be necessary to fit specific layouts.

Q4: How do automatic electrostatic spray guns improve environmental sustainability?

A4: They reduce paint overspray and VOC emissions by increasing transfer efficiency and enable the use of waterborne coatings, which have a lower environmental impact.

Q5: What safety measures should be considered when using electrostatic spray guns?

A5: Proper equipment grounding, avoiding flammable atmospheres, employee training, and regular maintenance are critical to prevent electrical hazards and ensure safe operation.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.