Content Menu

● Understanding Powder Coating Methods

>> What Is Manual Powder Coating?

>> What Are Reciprocators?

● Key Differences Between Reciprocators and Manual Coating

● Advantages of Reciprocators in Powder Coating Lines

>> H2: Enhanced Coating Uniformity and Quality

>> H2: Increased Productivity and Efficiency

>> H2: Improved Safety and Work Environment

>> H2: Versatility for Various Part Sizes and Shapes

● Advantages of Manual Powder Coating

>> H2: Lower Initial Investment

>> H2: Flexibility for Small Batches and Custom Jobs

>> H2: Simplicity and Ease of Use

● Challenges of Each Method

>> H2: Challenges with Reciprocators

>> H2: Challenges with Manual Coating

● When to Choose Reciprocators

● When to Choose Manual Coating

● Integrating Both Methods: Hybrid Approaches

● Frequently Asked Questions (FAQs)

Powder coating is a widely used finishing process that offers durable, high-quality surface protection for metal and other substrates. When setting up or upgrading a powder coating line, manufacturers often face a key decision: whether to use manual coating methods or invest in reciprocators—automated powder coating systems. Both approaches have distinct advantages and limitations depending on production volume, part complexity, cost considerations, and desired finish quality.

This article provides an in-depth comparison of reciprocators and manual powder coating, helping you determine which option best suits your powder coating line.

Understanding Powder Coating Methods

What Is Manual Powder Coating?

Manual powder coating involves operators using handheld spray guns to apply powder coating to parts. It is a labor-intensive process requiring skilled workers to ensure even coverage and consistent finish quality. Manual coating is often favored by smaller shops or those with low production volumes due to its flexibility and lower upfront equipment cost.

What Are Reciprocators?

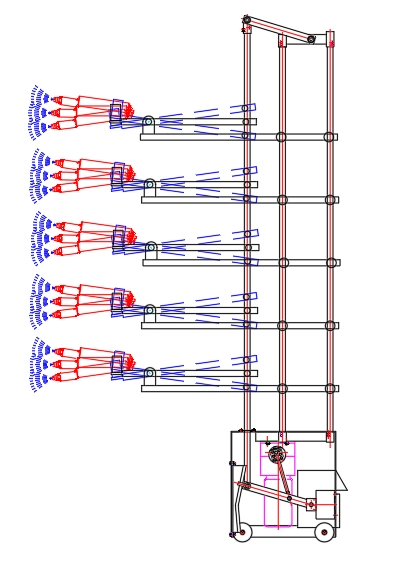

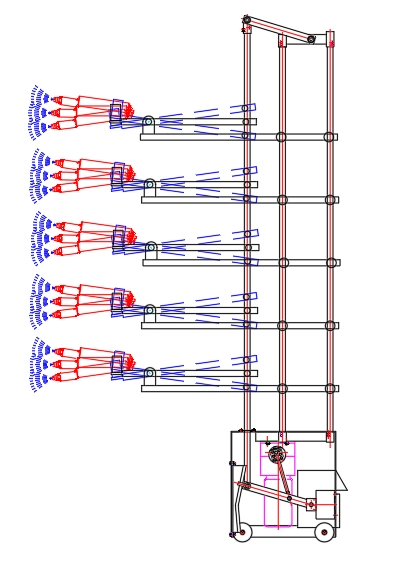

Reciprocators are automated systems that move powder coating spray guns in a controlled, repetitive motion—usually along one or more axes—to apply powder coating uniformly. They can be simple single-axis devices or advanced robotic arms capable of multi-axis articulation, programmed to handle complex part geometries. Reciprocators are integrated into powder coating booths and conveyor lines to automate the coating process, improving consistency and throughput.

Key Differences Between Reciprocators and Manual Coating

| Aspect | Manual Coating | Reciprocators |

| Labor Requirement | High; requires skilled operators | Low; automated process reduces labor needs |

| Initial Cost | Low; minimal equipment investment | High; requires capital investment in machinery |

| Production Volume | Suitable for low to medium volumes | Ideal for medium to high volumes |

| Coating Consistency | Variable; depends on operator skill | High; precise and repeatable application |

| Coverage of Complex Parts | Good with skilled operators, but challenging for intricate shapes | Excellent; robotic arms can reach complex angles |

| Powder Waste | Higher; overspray and uneven application common | Lower; optimized powder usage and minimal overspray |

| Safety | Exposure risk to operators | Improved; reduces operator exposure to powder and fumes |

| Flexibility | Very flexible; easy to switch parts and colors | Flexible but requires programming and setup |

Advantages of Reciprocators in Powder Coating Lines

H2: Enhanced Coating Uniformity and Quality

Reciprocators provide consistent, uniform powder distribution by moving spray guns in precise, repeatable patterns. This minimizes coating defects such as uneven thickness, runs, or thin spots that can occur with manual spraying. The ability to program stroke length and speed allows for optimized coverage tailored to part size and shape, resulting in superior finish quality.

H2: Increased Productivity and Efficiency

Automating the powder coating process with reciprocators significantly increases production rates. Since the system operates continuously and precisely, it reduces cycle times and labor costs. Operators can be redeployed to other tasks, improving overall plant efficiency. Additionally, reciprocators reduce powder waste by minimizing overspray and optimizing powder flow, lowering material costs.

H2: Improved Safety and Work Environment

Manual powder coating exposes workers to airborne powder and fumes, posing health risks. Reciprocators reduce operator exposure by automating the spraying process, enhancing workplace safety. This also helps companies comply with occupational health regulations.

H2: Versatility for Various Part Sizes and Shapes

Different types of reciprocators exist to accommodate diverse production needs:

- Single-Axis Reciprocators: Move spray guns along one axis, suitable for flat or simple-shaped parts.

- Dual-Axis Reciprocators: Allow movement in two axes for more complex spray patterns.

- Robotic Reciprocators: Employ multi-axis robotic arms for intricate parts with complex geometries, including internal surfaces and recesses.

This versatility enables manufacturers to coat a wide range of products efficiently on the same line.

Advantages of Manual Powder Coating

H2: Lower Initial Investment

Manual powder coating requires minimal capital expenditure compared to automated reciprocators. For businesses with low production volumes or limited budgets, manual coating is often more cost-effective.

H2: Flexibility for Small Batches and Custom Jobs

Manual coating is highly adaptable, allowing operators to quickly switch between different parts, colors, and coating specifications without the need for reprogramming or setup changes. This makes it ideal for small batch production, prototypes, or custom jobs.

H2: Simplicity and Ease of Use

Manual systems are straightforward to implement and maintain, requiring less technical expertise. They can be deployed quickly without complex integration into existing lines.

Challenges of Each Method

H2: Challenges with Reciprocators

- High Capital Cost: The upfront investment for reciprocators and associated automation equipment can be substantial.

- Programming and Maintenance: Requires skilled personnel to program and maintain the equipment.

- Less Suitable for Very Small or Highly Variable Production: Frequent changeovers may reduce efficiency.

H2: Challenges with Manual Coating

- Inconsistent Quality: Operator skill variability can lead to uneven finishes.

- Labor Intensive: Requires continuous attention and effort from operators.

- Higher Powder Waste: Manual spraying often results in more overspray and material loss.

- Safety Concerns: Increased exposure to powder particles and fumes.

When to Choose Reciprocators

- Your production volume is medium to high and requires consistent, high-quality finishes.

- You want to reduce labor costs and improve throughput.

- Your parts have complex shapes that benefit from precise, repeatable coating patterns.

- You prioritize workplace safety and regulatory compliance.

- You aim to minimize powder waste and improve material efficiency.

When to Choose Manual Coating

- Your business focuses on low volume or custom production.

- You have budget constraints limiting capital investment.

- You require maximum flexibility for frequent color or part changes.

- Your parts are relatively simple and can be coated effectively by skilled operators.

- You want to avoid the complexity of programming and maintaining automated systems.

Integrating Both Methods: Hybrid Approaches

Some manufacturers combine manual coating and reciprocators to balance flexibility and efficiency. For example, reciprocators can handle high-volume, standard parts, while manual coating is reserved for prototypes or complex custom jobs. This approach leverages the strengths of both methods.

Frequently Asked Questions (FAQs)

Q1: Can reciprocators coat all types of parts?

A1: Reciprocators are versatile and can coat a wide range of parts, especially with robotic arms that reach complex geometries. However, extremely irregular or delicate parts may still require manual touch-up.

Q2: How much powder waste reduction can reciprocators achieve?

A2: Reciprocators optimize powder flow and minimize overspray, often reducing powder waste by 20-30% compared to manual coating.

Q3: Are reciprocators difficult to maintain?

A3: While they require regular maintenance and occasional programming updates, reciprocators are generally reliable and designed for industrial use. Proper training ensures smooth operation.

Q4: What is the typical payback period for investing in reciprocators?

A4: Payback depends on production volume and labor costs but often ranges from 1 to 3 years due to increased efficiency and reduced waste.

Q5: Can manual coating achieve the same finish quality as reciprocators?

A5: Skilled operators can achieve good finish quality, but reciprocators provide more uniform and consistent results, especially on complex or high-volume parts.

[1] https://ems-powdercoating.com/powder-coating-reciprocator/

[2] https://patents.google.com/patent/CN105188958B/zh

[3] https://statfieldequipments.com/automatic-vs-manual-powder-coating-finding-the-right-fit-for-your-business/

[4] https://patents.google.com/patent/WO2014154668A1/zh

[5] https://ems-powdercoating.com/powder-coating-robots-reciprocators/

[6] https://www.linguee.com/english-chinese/translation/powder+coating+equipment.html

[7] https://www.hinahcoatingline.com/news/the-advantages-of-powder-coating-robot-in-your-powder-coating-line

[8] https://www.nordson.com/zh-cn/about-us/newsroom/industrial-coating-systems-news/complete-guide-to-powder-coating

[9] https://reasonablechoice.net/en/blog/automation-of-powder-coating-application

[10] https://patents.google.com/patent/CN115707332A/en

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.