Content Menu

● Understanding Manual Electrostatic Spray Guns

>> What Are Manual Electrostatic Spray Guns?

>> Advantages of Electrostatic Powder Coating

● Key Features of 2025's Best Manual Electrostatic Spray Guns

>> Ergonomic and Lightweight Design

>> Advanced Electrostatic Charging Technology

>> Precise Control and Adjustability

>> Durable Construction and Easy Maintenance

>> Compatibility with Different Powders and Materials

● Top Manual Electrostatic Spray Guns in 2025

>> Wagner GM 5000 EACW

>> OTSON OTS-3000+G7

>> Dezhou Aohai AH-S500

>> Gema OptiFlex Pro W

>> Cangzhou Astar Manual Electrostatic Powder Coating Gun

● How to Choose the Right Manual Electrostatic Spray Gun

>> Application Requirements

>> Powder Compatibility

>> Ease of Maintenance and Color Change

>> Budget and Support

● Best Practices for Using Manual Electrostatic Spray Guns

>> Surface Preparation

>> Gun Settings Optimization

>> Operator Training

>> Regular Maintenance

● Frequently Asked Questions (FAQs)

Manual electrostatic spray guns remain a critical tool for professionals seeking high-quality powder coating finishes in 2025. These guns utilize electrostatic charging technology to attract powder particles to the target surface, ensuring efficient, uniform coverage with minimal waste. With advancements in design, ergonomics, and control, the best manual electrostatic spray guns blend precision, ease of use, and durability to meet the demanding needs of industrial and commercial powder coating applications.

Understanding Manual Electrostatic Spray Guns

What Are Manual Electrostatic Spray Guns?

Manual electrostatic spray guns are handheld devices designed to apply powder coatings by electrically charging powder particles as they are sprayed. The charged particles are attracted to the grounded workpiece, resulting in a wrap-around effect and reducing overspray. Unlike automated systems, manual guns rely on an operator to control the application, offering flexibility for varied parts and complex shapes.

Advantages of Electrostatic Powder Coating

Electrostatic powder coating is valued for its durability, environmental benefits, and finish quality. Key advantages include:

- High transfer efficiency reduces powder waste and material costs.

- Excellent surface coverage with fewer coats required.

- Environmentally friendly with no solvents and low VOC emissions.

- Durable finishes resistant to corrosion, chemicals, and wear.

- Versatile application on metals, plastics, and other substrates.

Key Features of 2025's Best Manual Electrostatic Spray Guns

Ergonomic and Lightweight Design

Newer manual spray guns prioritize operator comfort with lightweight materials and ergonomic handles. This reduces fatigue during extended use and improves precision in coating application.

Advanced Electrostatic Charging Technology

Leading models incorporate optimized high-voltage power supplies to consistently charge powder particles at voltages around 60-100 kV. This ensures efficient attraction and adhesion to complex geometries.

Precise Control and Adjustability

Integrated control panels allow for fine-tuning of voltage, powder flow, and air pressure to adapt to different powder types and surface conditions. This flexibility helps achieve a uniform finish across diverse applications.

Durable Construction and Easy Maintenance

The best guns are built with corrosion-resistant materials suitable for harsh environments. Modular designs simplify cleaning and reduce downtime during maintenance or color changes.

Compatibility with Different Powders and Materials

Top manual electrostatic guns can handle various powders including epoxy, polyester, and polyurethane, making them adaptable for automotive, industrial, and architectural coatings.

Top Manual Electrostatic Spray Guns in 2025

Wagner GM 5000 EACW

The Wagner GM 5000 EACW is a high-pressure, aircoat manual electrostatic spray gun designed for water-based and powder coatings. It offers around 70 kV charging power with up to 250 bar material pressure, delivering excellent wrap-around and transfer efficiency. Its ergonomic, lightweight design reduces operator fatigue, while the integrated control panel provides precise adjustment for demanding coatings. Ideal for metal, plastic, and wood finishing, the GM 5000 combines efficiency with superior surface quality.

OTSON OTS-3000+G7

The OTSON OTS-3000+G7 manual liquid electrostatic spray gun excels at applying solvent and waterborne paints and lacquers with high atomization quality. Weighing only 470 grams, its lightness and low VOC emissions make it excellent for long operations. It features high transfer efficiency and easy maintenance, reducing overspray and ensuring consistent coating coverage with minimal waste.

Dezhou Aohai AH-S500

Designed with ergonomics and intelligent control systems, the AH-S500 from Dezhou Aohai provides advanced manual powder coating solutions. It features adjustable voltage and powder output for versatile, high-quality application on a variety of metal surfaces. The gun's reliable build and user-friendly interface make it ideal for intensive industrial use.

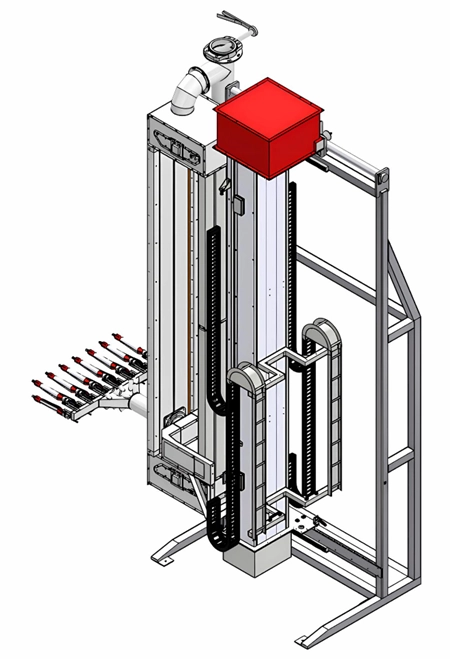

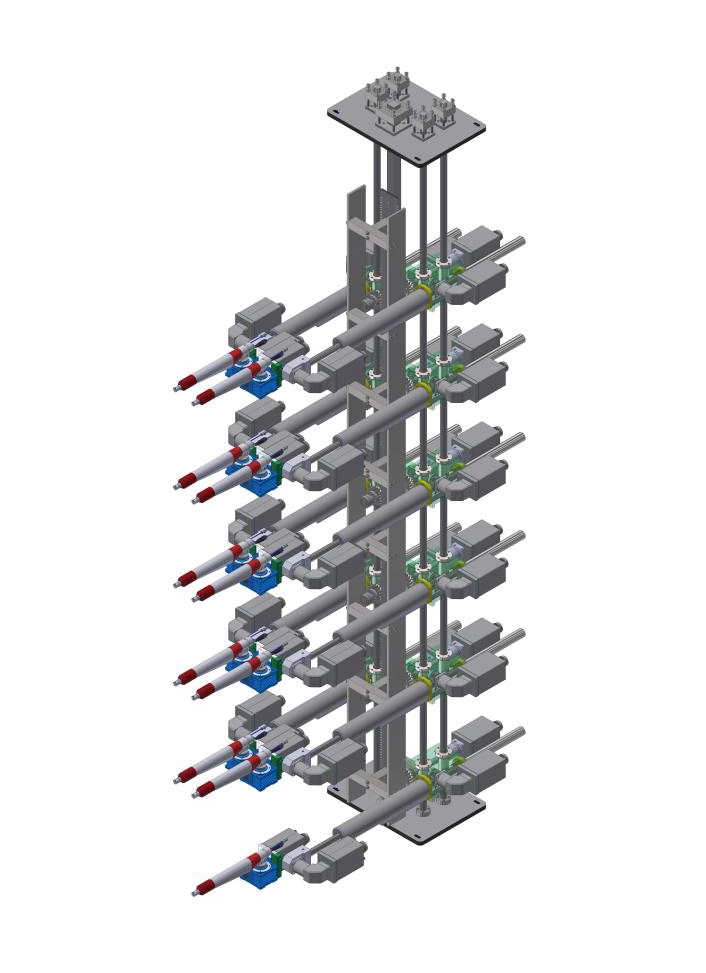

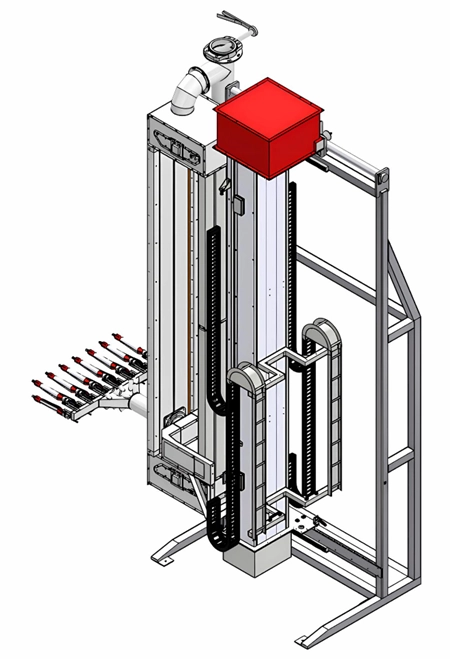

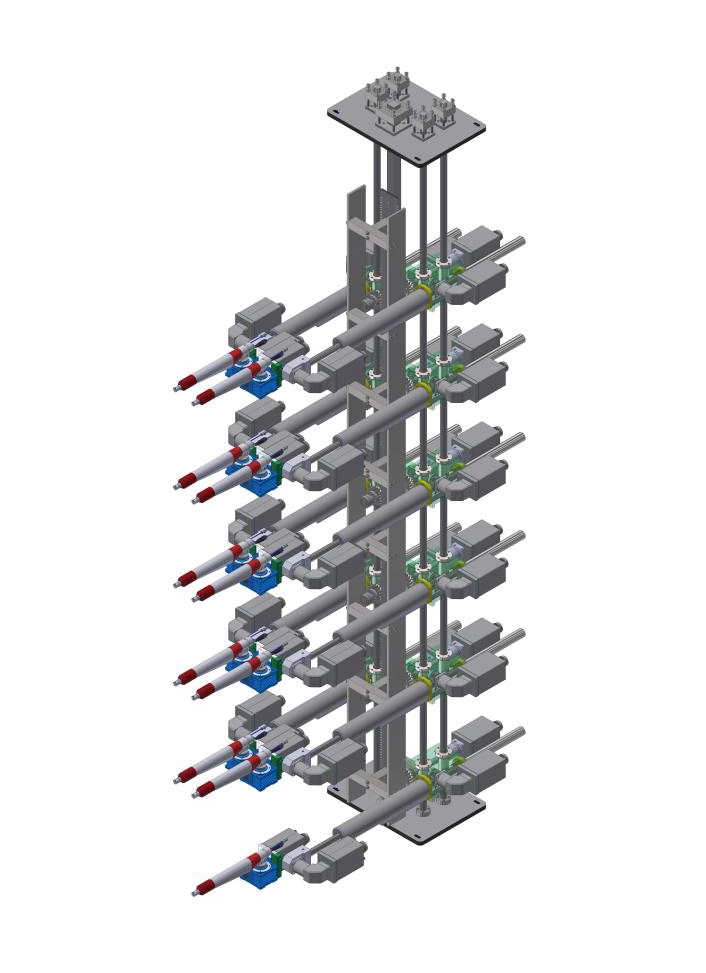

Gema OptiFlex Pro W

Gema's OptiFlex Pro W manual spray gun system integrates directly into existing lines with advanced injector technology and dense-phase powder flow. This ensures a stable and repeatable coating application even over long production runs. Its sturdy design and easy color change capabilities reduce downtime and improve productivity for professional powder coating shops.

Cangzhou Astar Manual Electrostatic Powder Coating Gun

From Cangzhou Astar, this full manual electrostatic powder coating gun offers a complete set suitable for industrial applications. Operating at 12 or 24 volts with output voltages up to 100 kV, it supports epoxy polyester powders and provides competitive pricing. Its durable steel construction and CE certification make it a reliable choice for workshops and manufacturing environments.

How to Choose the Right Manual Electrostatic Spray Gun

Application Requirements

Assess the size and complexity of parts to be coated. Ergonomics and gun weight are crucial if you have long, detailed jobs. For high-throughput operations, consider guns with better powder flow rates and stable voltage control.

Powder Compatibility

Verify the gun supports your powder type—epoxy, polyester, or specialty blends. Ensure it maintains efficient charging for the specific materials you use.

Ease of Maintenance and Color Change

Look for designs allowing quick disassembly and cleaning. Easy color changes improve efficiency in multi-color production environments.

Budget and Support

Balance performance features with cost and after-sales support. Established brands may offer better warranties and service networks, which matter in industrial production.

Best Practices for Using Manual Electrostatic Spray Guns

Surface Preparation

Clean and degrease parts to maximize coating adhesion. Proper grounding of the workpiece is critical for effective particle attraction.

Gun Settings Optimization

Adjust voltage, powder feed, and air pressure based on powder type and environmental conditions. Trial runs help find optimal parameters to ensure uniform coating thickness.

Operator Training

Train operators on proper gun handling, maintenance routines, and safety protocols to reduce defects and ensure consistent results.

Regular Maintenance

Frequent cleaning of nozzles, filters, and hoses prevents clogging and maintains spray quality. Replace worn parts promptly.

Frequently Asked Questions (FAQs)

Q1: What is the main advantage of manual electrostatic spray guns compared to automatic systems?

A1: Manual guns offer greater flexibility to coat complex shapes and small batches without large capital investment, making them ideal for varied or custom jobs.

Q2: Can manual electrostatic spray guns be used with all powder types?

A2: Most high-quality manual guns support common powders like epoxy and polyester, but it's important to confirm compatibility with specialty powders.

Q3: How do I reduce overspray when using an electrostatic spray gun?

A3: Optimize voltage and powder feed settings, ensure proper grounding, maintain correct spray distance, and use ergonomic gun handling techniques.

Q4: What maintenance is required for manual electrostatic powder guns?

A4: Routine cleaning of powder pathways and nozzles, inspecting electrical connections, and replacing worn parts are essential to maintain performance.

Q5: How important is operator training in manual electrostatic powder coating?

A5: Critical. Proper training reduces coating defects, ensures safety, and maximizes the efficiency and lifespan of the equipment.

[1] https://store.cetinc.com/wagner-electrostatic-spray-gun-gm-5000-eacw-high-pressure-aircoat-for-water-based-2309873/

[2] https://www.alibaba.com/showroom/electrostatic-spray-gun-coating-machine.html

[3] https://ai.otson.com/coating-electrostatic-spray/ots-3000-manual-liquid-electrostatic-spray-gun-led-version/

[4] https://www.alibaba.com/showroom/automatic-electrostatic-powder-coating-spray-gun.html

[5] https://www.gemapowdercoating.com/en/products/manual-equipment-and-guns

[6] https://chinese.alibaba.com/product-detail/High-quality-complete-set-Manual-electrostatic-60498847680.html

[7] https://www.powdercoatingonline.com/powder-coating-spray-guns-page-1/

[8] https://patents.google.com/patent/CN101184555B/zh

[9] https://www.ramseierkoatings.com/best-electrostatic-spray-guns-for-industrial-powder-coating-in-2025.html

[10] https://patents.google.com/patent/CN101014415A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.