Content Menu

● Introduction

● What Is Powder Coating and Why DIY?

>> What Is Powder Coating?

>> Benefits of DIY Powder Coating Equipment

● Essential Components of DIY Powder Coating Equipment

>> Powder Coating Gun

>> Air Compressor

>> Powder Coating Booth

>> Curing Oven

● Step-by-Step DIY Powder Coating Process

>> 1. Surface Preparation

>> 2. Setting Up the Equipment

>> 3. Applying the Powder

>> 4. Curing the Coating

● Tips for Successful DIY Powder Coating

● Advantages of Powder Coating Over Traditional Painting

● Frequently Asked Questions (FAQs)

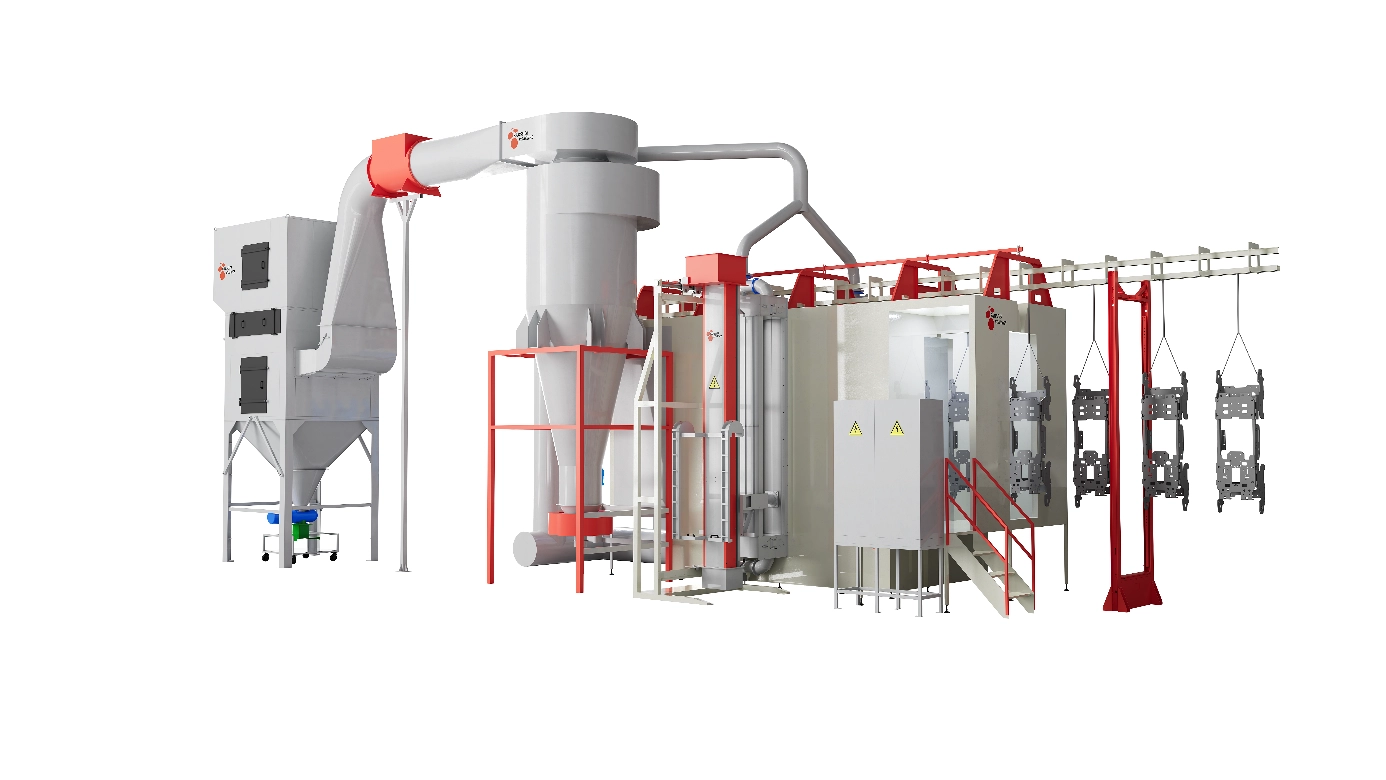

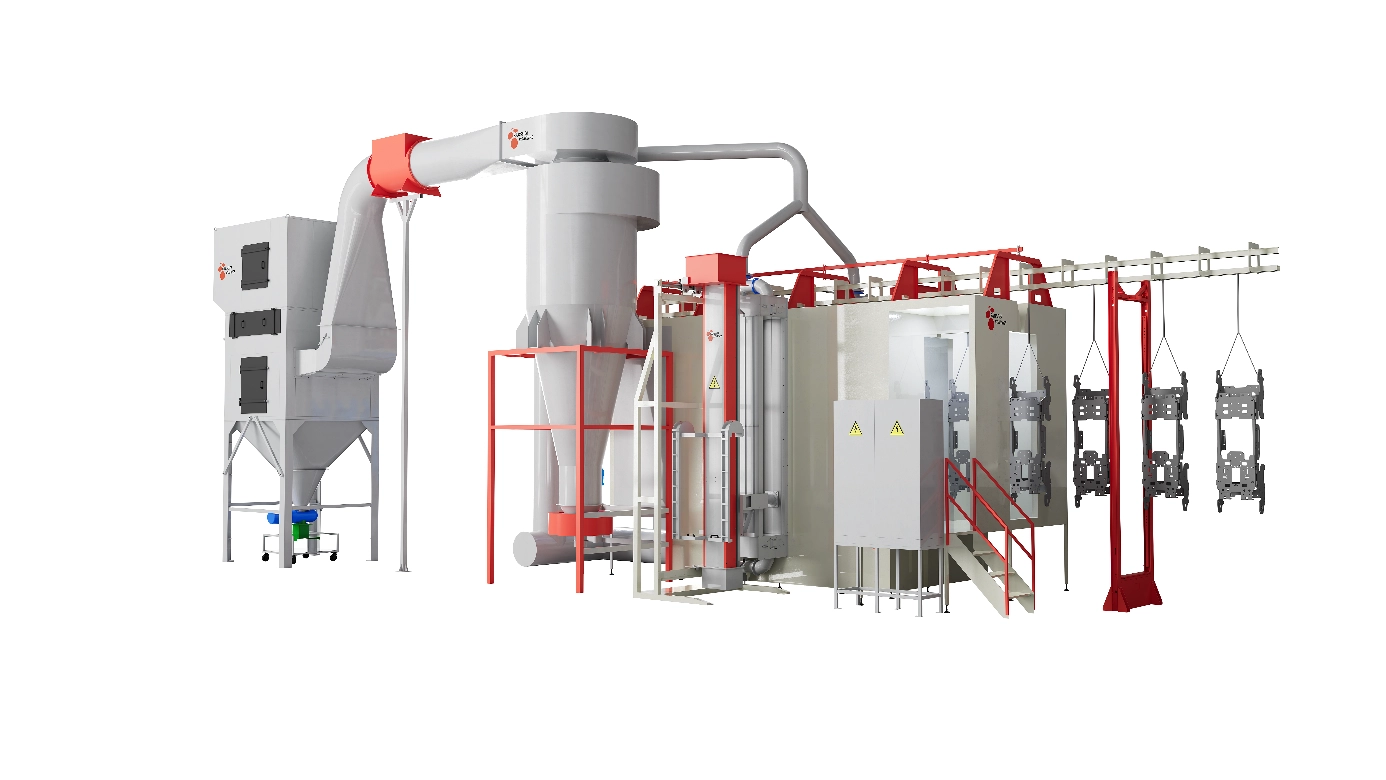

Introduction

As a leading Chinese manufacturer, supplier, and OEM service provider of powder coating equipment, we understand the growing interest in "powder coating equipment DIY" among hobbyists, small businesses, and even industrial users worldwide. This comprehensive guide explores how to build, operate, and optimize your own powder coating equipment, empowering you to achieve professional-grade finishes at home or in your workshop. Whether you are a brand, wholesaler, or producer looking to expand your capabilities or a DIY enthusiast eager to learn the craft, this article covers everything you need to know.

What Is Powder Coating and Why DIY?

What Is Powder Coating?

Powder coating is a finishing process where a dry powder is electrostatically applied to a surface and then cured under heat to form a durable, high-quality coating. Unlike traditional liquid paints, powder coating is less messy, more environmentally friendly, and produces a tougher finish.

Benefits of DIY Powder Coating Equipment

- Cost Savings: Building your own powder coating equipment reduces expenses compared to buying commercial units.

- Customization: Tailor your setup to your specific needs and parts.

- Quality Control: Full control over the coating process ensures superior results.

- Convenience: Perform powder coating at your own pace and schedule.

- Learning Experience: Gain valuable skills in surface finishing technology[4][7].

Essential Components of DIY Powder Coating Equipment

Powder Coating Gun

The heart of any powder coating setup is the powder coating gun. DIY options range from simple homemade guns using air dusters and conduit pipes to more advanced models with ion generators for electrostatic charging.

- A typical DIY gun can be made from an air duster connected to a compressor, brass connectors, tubing, and a high-voltage power supply generating around 20,000 volts to charge the powder particles[7].

- Commercial powder coating guns are also available for integration with DIY systems[1].

Air Compressor

A reliable air compressor is crucial to deliver consistent airflow. While large tanks (e.g., 60 gallons) are beneficial, smaller compressors (2.5 gallons) suffice for most DIY projects[2].

Powder Coating Booth

A well-ventilated booth with proper filtering, lighting, and a rotating system improves coating quality and safety. DIY booths can be constructed from MDF or plywood with added LED lighting and 3D-printed rotating carousels for part handling[4].

Curing Oven

Powder coating requires curing at elevated temperatures (typically 180-200°C). Small toaster ovens work well for small parts, while larger wall-mounted ovens suit bigger components[2][4].

Step-by-Step DIY Powder Coating Process

1. Surface Preparation

- Thoroughly clean and degrease parts using acetone or specialized degreasers.

- Remove rust, old paint, and contaminants by sandblasting or sanding.

- Ensure parts are completely dry before coating[2][4].

2. Setting Up the Equipment

- Connect the powder coating gun to the air compressor.

- Attach the grounding clip to the part to ensure proper electrostatic charge.

- Prepare the powder supply in the gun's cup or hopper[5][7].

3. Applying the Powder

- Hold the gun approximately 8 inches from the part.

- Use the trigger to control powder flow and a foot pedal to control electrical charge.

- Apply powder evenly, paying attention to hard-to-reach areas.

- Use gravity and part orientation to achieve full coverage[5].

4. Curing the Coating

- Place the coated part in the preheated oven.

- Cure for 10 to 20 minutes, depending on powder specifications.

- Allow parts to cool naturally before handling[2][4].

Tips for Successful DIY Powder Coating

- Always wear protective gear, including masks, gloves, and eye protection, to avoid inhaling powder particles.

- Ensure your workspace is well-ventilated.

- Ground all equipment properly to prevent electrical hazards.

- Experiment with different powders and finishes to achieve desired aesthetics.

- Maintain your equipment regularly for consistent performance[4][5].

Advantages of Powder Coating Over Traditional Painting

| Feature | Powder Coating | Traditional Painting |

| Toxicity | Low (no solvents) | Higher (solvents used) |

| Drying Time | Minutes in oven | Hours to days |

| Durability | Hard, chip-resistant finish | Softer, prone to chipping |

| Environmental Impact | Less waste, easy cleanup | More waste, toxic runoff |

| Application Mess | Minimal dust and overspray | Messy with drips and spills |

Frequently Asked Questions (FAQs)

Q1: Can I use a regular kitchen oven for powder coating?

A1: Yes, for small parts, a toaster or kitchen oven works well, but ensure it is dedicated to powder coating due to potential contamination[2][4].

Q2: Is DIY powder coating safe?

A2: Yes, with proper ventilation, grounding, and protective equipment, DIY powder coating is safe. Avoid inhaling powder particles and follow electrical safety practices[4][5].

Q3: What powders are best for DIY powder coating?

A3: Polyester powders are common for outdoor durability, while epoxy powders are good for indoor use. Many colors and finishes are available commercially[7].

Q4: How much does it cost to build a DIY powder coating setup?

A4: Costs vary but can be as low as a few hundred dollars for basic equipment, much cheaper than commercial systems[7].

Q5: Can I powder coat non-metal materials?

A5: Powder coating is primarily for metal substrates but some powders and processes allow coating of certain plastics and composites with proper preparation[4].

[1] https://www.youtube.com/watch?v=aevtL9Id4ms

[2] https://www.youtube.com/watch?v=85ZqeC3xXFc

[3] https://www.reddit.com/r/DIY/comments/67o5u5/powder_coating_at_home_is_cheap_and_easy/

[4] https://indystry.cc/how-to-diy-powder-coating/

[5] https://www.rodauthority.com/tech-stories/paint-body/powder-coating-at-home-a-how-to-guide-for-the-home-handyman/

[6] https://www.dlhitech.gov.cn/resources/news/newsConstantImages/20200825172656759.pdf

[7] https://airgunforums.co.uk/threads/powder-coating-diy-at-home.31970/

[8] https://www.desfarges-charpente-menuiserie.fr/2020/Mar/26_363.html

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.