Content Menu

● Understanding Electrostatic Spray Guns

>> How Electrostatic Spray Guns Work

● Key Factors to Consider When Choosing an Electrostatic Spray Gun

>> 1. Type of Coating Material

>> 2. Production Volume and Part Size

>> 3. Voltage and Charging Technology

>> 4. Atomization Technology

>> 5. Ergonomics and Maintenance

● Detailed Selection Criteria

>> H2: Coating Material Compatibility

>>> H3: Powder Coatings

>>> H3: Liquid Coatings

>> H2: Production Environment and Part Specifications

>>> H3: Batch vs. Conveyor Systems

>>> H3: Part Geometry and Size

>> H2: Technical Features of Electrostatic Spray Guns

>>> H3: Voltage and Safety

>>> H3: Atomization and Spray Patterns

>>> H3: Maintenance and Ergonomics

● Practical Tips for Choosing and Using Electrostatic Spray Guns

● Frequently Asked Questions (FAQs)

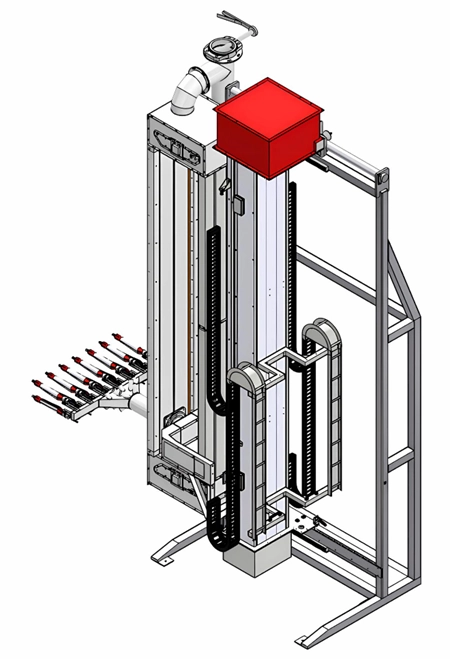

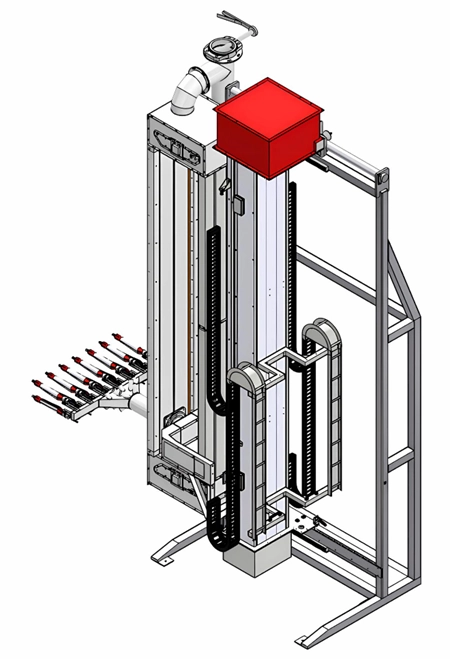

Electrostatic spray guns are essential tools in modern coating lines, offering superior finish quality, material savings, and environmental benefits. However, selecting the right electrostatic spray gun requires understanding various factors such as coating type, part geometry, production scale, and technical features of the spray gun. This comprehensive guide will help you navigate the selection process to optimize your coating line's efficiency and finish quality.

Understanding Electrostatic Spray Guns

Electrostatic spray guns use an electrostatic charge to attract coating particles—either powder or liquid paint—to a grounded workpiece. This technology ensures a uniform, durable coating with minimal overspray and waste.

How Electrostatic Spray Guns Work

- The spray gun imparts a positive electrical charge to the coating material.

- The workpiece is grounded, creating an opposite charge.

- Charged particles are attracted to the workpiece, wrapping around edges and recesses for even coverage.

- The coating is then cured, typically by baking or drying, to form a hard, protective finish.

This process is widely used in automotive, agricultural, medical, and industrial equipment manufacturing due to its efficiency and quality advantages.

Key Factors to Consider When Choosing an Electrostatic Spray Gun

1. Type of Coating Material

Electrostatic spray guns are designed to work with different coating materials:

- Powder Coatings: Charged powder particles adhere to the grounded surface and are cured with heat. Powder coatings offer thick, durable finishes without solvents or VOCs.

- Liquid Coatings: Charged liquid paint particles provide smooth, even coverage with less overspray than conventional spray guns.

Choosing a gun compatible with your coating material is critical. Some guns are optimized for powder, others for liquid, and some can handle both with interchangeable components.

2. Production Volume and Part Size

- Batch vs. Conveyor Line: Batch-style electrostatic spray guns provide flexibility for small lot sizes, complex parts, or oversized items that don't fit conveyor lines. Conveyor line guns are designed for high-volume, uniform parts.

- Part Geometry: Complex shapes, cavities, and recesses require guns with adjustable spray patterns and high voltage to ensure full coverage.

3. Voltage and Charging Technology

The electrostatic charge level affects transfer efficiency and coating uniformity:

- Higher voltage guns (up to 93 kV) offer better wrap-around and material savings.

- Some guns feature automatic current limiting to adjust charge for different part profiles, improving coverage in hard-to-reach areas.

- Safety features such as current limiting and insulation are essential to protect operators and equipment.

4. Atomization Technology

- Air Spray: Uses compressed air to atomize the coating material; suitable for fine finishes.

- High Volume Low Pressure (HVLP): Provides efficient atomization with reduced overspray and better transfer efficiency.

- Some advanced guns combine both technologies for versatility.

5. Ergonomics and Maintenance

- Comfortable handle design reduces operator fatigue.

- Quick-flush fluid passages and rugged construction minimize downtime and maintenance costs.

- Availability of multiple fluid tips and air caps allows customization for different coatings and part sizes.

Detailed Selection Criteria

H2: Coating Material Compatibility

H3: Powder Coatings

Powder electrostatic spray guns must control powder flow, pressure, and charge precisely. Adjusting parameters like spray pressure, gas flow rate, nozzle size, and spray distance is critical to achieving uniform coating thickness. The gun should allow fine-tuning to match specific powders and workpieces.

H3: Liquid Coatings

For liquid paints, the gun's atomization quality and charge stability are paramount. The gun should maintain a consistent charge on paint particles to ensure adhesion and reduce waste. Some guns use external electrodes or internal charging needles to optimize performance.

H2: Production Environment and Part Specifications

H3: Batch vs. Conveyor Systems

Batch systems offer flexibility for small or complex parts and allow the use of non-traditional coatings like nylon or vinyl. Conveyor systems are suited for high throughput with uniform parts but may limit coating options and part size.

H3: Part Geometry and Size

Parts with cavities, crevices, or large dimensions require guns with adjustable spray patterns and higher voltage to ensure complete coverage. Features like automatic current limiting help adapt the charge to complex shapes.

H2: Technical Features of Electrostatic Spray Guns

H3: Voltage and Safety

Higher voltage guns provide better transfer efficiency but must include safety features such as current limiting and proper insulation. Some guns achieve voltages up to 93 kV, maximizing coating wrap and reducing material waste.

H3: Atomization and Spray Patterns

Selecting the right aircap and fluid tip combination is essential for consistent atomization. HVLP guns reduce overspray and improve transfer efficiency, while air spray guns may be preferred for certain finishes.

H3: Maintenance and Ergonomics

Guns with quick-flush fluid passages simplify cleaning, reducing downtime. Ergonomic designs improve operator comfort and productivity, especially in manual applications.

Practical Tips for Choosing and Using Electrostatic Spray Guns

- Test with Your Materials: Always test the gun with your specific coating materials and parts to optimize settings.

- Adjust Parameters: Fine-tune spray pressure, voltage, and spray distance for uniform coverage.

- Consider Safety: Ensure the gun meets safety standards and includes features like automatic current limiting.

- Plan for Maintenance: Choose guns with easy-to-clean designs and readily available replacement parts.

- Match to Production Needs: Select batch or conveyor-compatible guns based on your production volume and part complexity.

Frequently Asked Questions (FAQs)

Q1: Can one electrostatic spray gun handle both powder and liquid coatings?

A1: Some advanced electrostatic spray guns offer interchangeable components or dual functionality, but typically, powder and liquid coatings require specialized guns optimized for each type.

Q2: What voltage is ideal for electrostatic spray guns?

A2: Voltages up to 93 kV are available and provide superior transfer efficiency. The ideal voltage depends on part size, geometry, and coating material.

Q3: How important is spray gun ergonomics?

A3: Ergonomics significantly affect operator comfort and productivity, especially in manual spray applications. A well-designed handle reduces fatigue and improves precision.

Q4: Can electrostatic spray guns coat complex shapes effectively?

A4: Yes, guns with adjustable charge and spray patterns, along with features like automatic current limiting, ensure even coating on complex geometries.

Q5: What maintenance is required for electrostatic spray guns?

A5: Regular cleaning of fluid passages, inspection of electrodes, and replacement of worn tips or caps are essential to maintain performance and safety.

[1] https://www.powderspraymachine.com/tune-the-powder-spray-gun-for-stable-coating-thickness/

[2] https://patents.google.com/patent/CN1171684C/zh

[3] https://www.precisioncoatingtech.com/electrostatic-spray-coating/

[4] https://patents.google.com/patent/CN118142738A/zh

[5] https://www.nordson.com/en/products/industrial-coating-systems-products/trilogy-electrostatic---spray-systems

[6] https://patents.google.com/patent/CN101014415A/zh

[7] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/electrostatic-spray-gun-basics.html

[8] https://patents.google.com/patent/CN103025436B/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.