Content Menu

● Understanding Uniform Coating Thickness

● Challenges in Achieving Uniform Coating Thickness

● Working Principle of Electrostatic Spray Guns

>> What is Electrostatic Spraying?

>> Components of an Electrostatic Spray Gun

>> How It Works

● Advantages of Electrostatic Spray Guns for Uniform Coating Thickness

>> 1. Enhanced Transfer Efficiency

>> 2. Improved Surface Coverage

>> 3. Reduced Overspray and Environmental Impact

>> 4. Consistent Droplet Size and Distribution

>> 5. Faster Drying and Improved Adhesion

● Types of Electrostatic Spray Guns

>> Electrostatic Air Spray Guns

>> Electrostatic Airless Spray Guns

>> Electrostatic Powder Spray Guns

● Practical Tips to Achieve Uniform Coating Thickness Using Electrostatic Spray Guns

>> Preparation and Setup

>> Environmental Control

>> Material Selection and Handling

● Case Studies of Electrostatic Spray Guns in Achieving Uniform Coatings

>> Automotive Industry

>> Electronics Manufacturing

>> Furniture and Woodworking

● Maintenance and Safety Tips for Electrostatic Spray Guns

>> Regular Maintenance

>> Safety Precautions

● Frequently Asked Questions (FAQs)

● Conclusion

Achieving uniform coating thickness is a critical objective in many industries, from automotive manufacturing to electronics and furniture finishing. The quality, durability, and aesthetics of a coated product highly depend on an even and consistent application of the coating material. Electrostatic spray guns have revolutionized the coating industry by enhancing the uniformity and efficiency of coatings. This article explores how electrostatic spray guns help you achieve uniform coating thickness, detailing their working principles, benefits, essential components, and practical applications.

Understanding Uniform Coating Thickness

Uniform coating thickness refers to the consistent layer of the coating material applied across the entire surface of a substrate. Achieving this goal ensures:

- Enhanced durability and corrosion resistance

- Improved surface appearance and finish

- Optimal material usage and cost efficiency

- Better control over product quality and performance

Even minor variations in thickness can lead to defects like uneven drying, cracking, flaking, or poor adhesion. Therefore, precise control during the application stage is essential.

Challenges in Achieving Uniform Coating Thickness

Before delving into how electrostatic spray guns address this challenge, it is vital to understand the common obstacles faced during conventional coating applications:

- Overspray and Material Waste: Traditional spraying technologies often lead to excessive overspray, causing waste and inconsistency.

- Uneven Distribution: Gravity, surface geometry, and operator technique can lead to uneven thickness, especially on complex shapes.

- Environmental Factors: Airflow, temperature, and humidity can affect droplet behavior and drying patterns, resulting in non-uniform coatings.

- Recoil and Bounce-back: Some spray particles may bounce off the surface, creating an irregular coating layer.

Electrostatic spray guns have been developed to overcome these issues, enabling more precise and efficient coating application.

Working Principle of Electrostatic Spray Guns

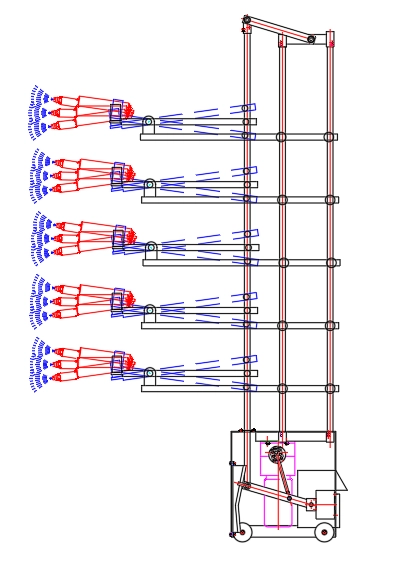

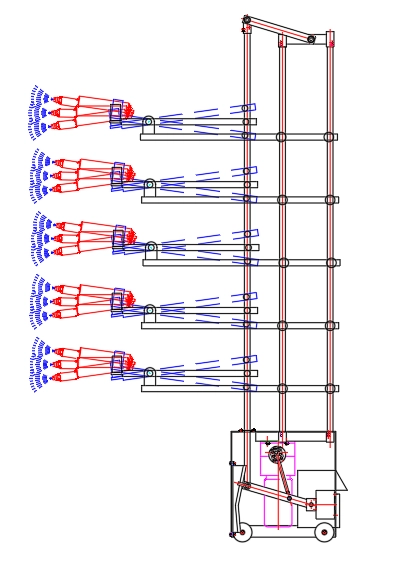

What is Electrostatic Spraying?

Electrostatic spraying is an advanced coating method where the coating material is atomized into fine droplets and then electrically charged. These charged droplets are attracted to the oppositely charged or grounded workpiece, resulting in better transfer efficiency and uniform deposition.

Components of an Electrostatic Spray Gun

An electrostatic spray gun typically includes:

- Atomizing Nozzle: Breaks the coating material into fine droplets.

- Electrification Electrode: Imparts an electric charge to each droplet.

- High-Voltage Power Supply: Provides the charge needed to electrify the droplets.

- Grounding System: Ensures the workpiece or spray target has an opposite or neutral charge to attract the droplets.

- Air Supply (in air-atomized guns): Assists with atomization and spray control.

How It Works

1. The coating material is pressurized and forced through the nozzle to form a spray pattern.

2. As the droplets exit the nozzle, they pass an electrode that charges them with either a positive or negative polarity.

3. The substrate being coated is electrically grounded or given an opposite charge.

4. The electrostatic force attracts the droplets to the surface, causing them to wrap around and coat even hidden or recessed areas.

5. The charged droplets repel each other, improving dispersion and preventing clumping.

This process leads to a more uniform coating thickness with minimal overspray.

Advantages of Electrostatic Spray Guns for Uniform Coating Thickness

1. Enhanced Transfer Efficiency

Electrostatic attraction forces droplets to stick to the surface, increasing transfer efficiency to up to 90% or more, compared to 30-60% with conventional spray methods. Less paint or powder is wasted, and the coating thickness becomes more even.

2. Improved Surface Coverage

Because charged particles are attracted and wrap around the substrate, even complex geometries like corners and crevices receive consistent coating layers. This means fewer touch-ups and enhanced production quality.

3. Reduced Overspray and Environmental Impact

By reducing the amount of material that misses the target, electrostatic spraying decreases solvent emissions and material waste. This approach contributes to cost savings and reduced environmental footprint.

4. Consistent Droplet Size and Distribution

Electrostatic spray guns produce uniformly charged droplets with consistent size and velocity, leading to a homogenous paint film.

5. Faster Drying and Improved Adhesion

The uniform coating layer has consistent thickness, translating into even drying rates and fewer defects such as runs or sags, which promotes better adhesion and durability.

Types of Electrostatic Spray Guns

Electrostatic Air Spray Guns

These guns use compressed air to atomize the coating and simultaneously charge the droplets electrostatically. They are suitable for a wide range of materials including aqueous and solvent-based coatings.

Electrostatic Airless Spray Guns

Airless guns create high-pressure streams to atomize the material, then apply an electrostatic charge. They are known for producing finer finishes and are especially effective for thick coatings or industrial applications.

Electrostatic Powder Spray Guns

Instead of liquid paint, these guns spray electrically charged powder particles, which adhere to the electrically grounded surface. They are widely used in powder coating processes where uniform thickness and durability are required.

Practical Tips to Achieve Uniform Coating Thickness Using Electrostatic Spray Guns

Preparation and Setup

- Proper Grounding: Ensure the substrate is properly grounded or charged with an opposite polarity for effective attraction.

- Correct Voltage and Polarity: Adjust the voltage supply and polarity according to the coating material and substrate to optimize droplet behavior.

- Optimal Spray Distance: Maintain the recommended distance between the gun and the workpiece; too close can cause buildup, too far reduces transfer efficiency.

- Consistent Gun Movement: Use steady, even passes with overlap to ensure the coating is applied uniformly.

Environmental Control

- Maintain temperature and humidity within the recommended ranges to avoid uneven drying.

- Minimize airflow disturbances that can deflect charged droplets.

Material Selection and Handling

- Use coatings compatible with electrostatic processes.

- Ensure the material is properly mixed and strained to avoid nozzle clogs or inconsistent atomization.

Case Studies of Electrostatic Spray Guns in Achieving Uniform Coatings

Automotive Industry

Automakers use electrostatic spray guns extensively for painting car bodies and parts. The technique enables uniform coverage even on complex shapes like door handles and wheel wells, reducing defects and improving finish quality.

Electronics Manufacturing

Electrostatic spraying allows thin, consistent coatings of conformal protectants or insulating materials on circuit boards, providing protection while maintaining tight thickness tolerances.

Furniture and Woodworking

Electrostatic spray guns provide smooth, even finishes on furniture surfaces, reducing material usage and enhancing the appearance compared to traditional brushing or rolling methods.

Maintenance and Safety Tips for Electrostatic Spray Guns

Regular Maintenance

- Clean the nozzle and electrode tips regularly to prevent clogging or charge disruption.

- Inspect hoses and grounding connections for damage.

- Replace worn parts to maintain spraying performance and coating uniformity.

Safety Precautions

- Use appropriate personal protective equipment (PPE) due to high voltage presence.

- Prevent sparks or ignition sources near flammable coatings and powder materials.

- Follow manufacturer guidelines for voltage settings and grounding procedures.

Frequently Asked Questions (FAQs)

Q1: Can electrostatic spray guns be used with all types of coatings?

A1: While many coatings can be applied with electrostatic spray guns, water-based and solvent-based paints as well as powders are most common. Some specialty coatings may require compatibility testing.

Q2: How close should I hold the electrostatic spray gun to the surface?

A2: The optimal distance usually ranges from 6 to 12 inches, depending on the gun and coating type. Too close can lead to excess buildup; too far reduces transfer efficiency.

Q3: How does electrostatic spraying reduce material waste?

A3: Charged droplets are attracted to the grounded surface, minimizing overspray and bounce-back, thereby conserving more coating material.

Q4: Can electrostatic spray guns be used on non-conductive materials?

A4: Yes, but non-conductive materials usually need special conductive primers or grounding techniques to achieve proper electrostatic attraction.

Q5: Are electrostatic spray guns suitable for outdoor use?

A5: They can be used outdoors, but weather conditions such as wind and humidity must be controlled to maintain spraying accuracy and uniformity.

Conclusion

Electrostatic spray guns significantly enhance the ability to achieve uniform coating thickness, a fundamental requirement across numerous manufacturing and finishing processes. By electrically charging the coating droplets, these guns improve transfer efficiency, reduce overspray, ensure even surface coverage, and handle complex geometries with ease. Proper setup, environmental control, and maintenance maximize the benefits and result in superior coating quality and durability. As industries continue to demand high-quality finishes with cost-effectiveness and environmental responsibility, electrostatic spray technology remains an indispensable tool.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.