Introduction to Manual Spray Booth System

As a renowned Manual Spray Booth System Supplier with over 38 years of experience in innovating spraying equipment, we specialize in providing high-performance and stable solutions for powder coating applications. Our Manual Spray Booth System is designed to cater to the diverse needs of industries seeking efficient and cost-effective powder coating processes. This system is ideal for small to medium-sized production environments where manual control and flexibility are essential.

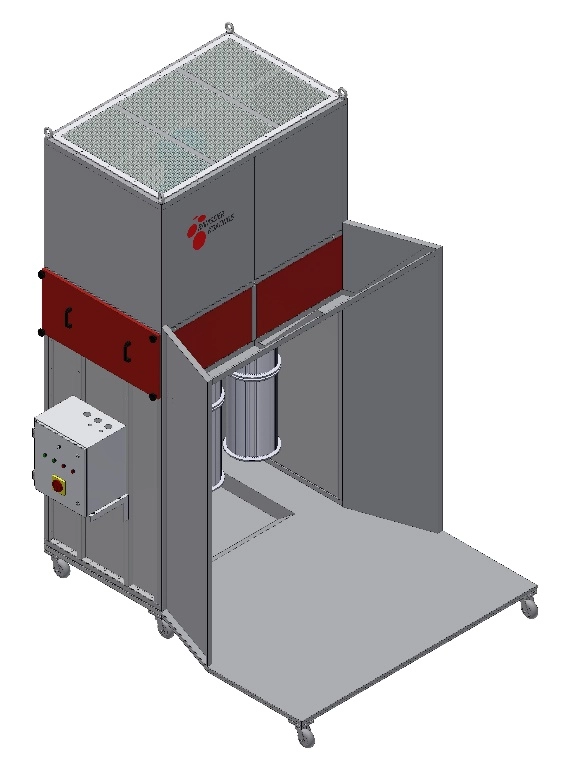

Our Manual Spray Booth System is engineered to ensure a controlled environment for powder coating operations. It features a robust booth enclosure typically made of metal or plastic, which effectively contains overspray and debris, protecting the surrounding environment. The system includes a powder feed system, spray gun, and a filtration system to capture overspray particles and fumes. The booth's interior is well-lit, allowing operators to clearly view the workpiece during the coating process.

Operation Method of Manual Spray Booth System

Operating a Manual Spray Booth System involves several key steps:

1. Preparation: Ensure the booth is properly ventilated and all safety devices are functioning correctly. Conduct regular checks for leaks and ensure the water level (if applicable) is within the recommended range. As a Manual Spray Booth System Supplier, we emphasize the importance of safety and efficiency in every aspect of our systems.

2. Startup Procedure: Switch on the mains isolator and press the start button. The fans and pumps will activate, and the extraction system will be ready for use. Check the manometer to confirm the filter system is operating correctly. Our systems are designed to provide a seamless startup process, ensuring that operators can focus on the coating process.

3. Spraying: Use the spray gun to apply powder coating to the workpiece. Ensure even coverage and avoid spraying directly at one part of the water screen (if using a water curtain system). Our Manual Spray Booth System allows for precise control over the coating process, making it ideal for custom jobs and small batches.

4. Post-Operation: After completing the coating process, turn off the equipment and perform routine maintenance tasks such as cleaning the booth and checking the filtration system. Regular maintenance is crucial to maintaining the efficiency and longevity of our Manual Spray Booth System.

Features of Manual Spray Booth System

Our Manual Spray Booth System offers several distinctive features that make it a preferred choice among industries:

Flexibility: Suitable for small batch to conveyorized production, allowing for flexible production scheduling. As a Manual Spray Booth System Supplier, we understand the need for adaptability in various production settings.

Cost-Effectiveness: Offers a cost-efficient solution compared to automated systems, ideal for smaller production volumes. This makes our Manual Spray Booth System an attractive option for businesses looking to manage costs while maintaining quality.

Easy Maintenance: Designed for simplicity, making maintenance tasks straightforward and reducing downtime. Our systems are engineered to minimize technical issues, ensuring continuous operation.

Safety Compliance: Constructed with safety in mind, adhering to relevant safety standards and regulations. We prioritize the safety of operators and the environment, ensuring our Manual Spray Booth System meets all necessary safety protocols.

Production Process of Manual Spray Booth System

As a Manual Spray Booth System Supplier, our production process involves several stages:

1. Design and Planning: We work closely with clients to understand their specific needs and design the booth accordingly. This includes determining the booth size, layout, and required features such as ventilation and filtration systems. Our expertise in customizing Manual Spray Booth Systems ensures that each system meets the unique requirements of our clients.

2. Material Selection: We use high-quality materials that are durable and compliant with safety standards. This includes non-flammable materials for the booth enclosure and explosion-proof fixtures. Our commitment to quality ensures that our Manual Spray Booth System performs optimally and safely.

3. Manufacturing: The booth enclosure is fabricated using metal or plastic, depending on the client's requirements. The powder feed system, spray gun, and filtration system are assembled and integrated into the booth. Our manufacturing process is streamlined to ensure efficiency and precision in every aspect of our Manual Spray Booth System.

4. Quality Control: Each system undergoes rigorous testing to ensure it meets our high standards for performance and safety. As a Manual Spray Booth System Supplier, we guarantee that our systems are reliable and efficient.

5. Installation and Training: We provide comprehensive installation services and training for operators to ensure smooth integration into existing production lines. Our support extends beyond the initial installation, ensuring that our clients can maximize the potential of their Manual Spray Booth System.

Why Choose Our Manual Spray Booth System?

As a trusted Manual Spray Booth System Supplier, we offer:

Expertise: With decades of experience, we understand the intricacies of powder coating and tailor our systems to meet specific industry needs.

Customization: Our systems can be customized to fit unique production requirements, ensuring optimal performance and efficiency.

Support: We provide ongoing support and maintenance services to ensure our systems continue to perform at their best.

Whether you are looking to enhance your existing powder coating capabilities or establish a new production line, our Manual Spray Booth System is designed to deliver high-quality finishes while ensuring safety and efficiency. As a leading Manual Spray Booth System Supplier, we are committed to providing innovative solutions that meet the evolving needs of industries worldwide.

Benefits of Using a Manual Spray Booth System

Our Manual Spray Booth System offers several benefits that make it an essential tool for various industries:

Improved Safety: By containing hazardous materials and fumes, our system protects operators and the environment. This is a critical aspect of our design, as safety is paramount in any production environment.

Better Finish: The controlled environment provided by our Manual Spray Booth System ensures a high-quality finish on coated surfaces. This is achieved through precise control over temperature, humidity, and dust levels.

Increased Productivity: By reducing the time spent on cleanup and preparation, our system helps increase productivity. This is particularly beneficial in small to medium-sized production settings where efficiency is crucial.

Flexibility and Adaptability: Our Manual Spray Booth System is ideal for custom jobs and small batches, allowing for intricate detailing that automated systems may struggle to replicate.

Types of Manual Spray Booths

There are various types of manual spray booths available, each suited to different applications:

Cross-Draft Spray Booths: These booths have air flowing perpendicular to the spray area, making them easy to construct and cost-effective. However, they may not provide the best airflow for larger vehicles.

Downdraft Spray Booths: These booths draw air downward, providing a stable environment suitable for painting large vehicles. They are more efficient and offer better airflow control.

Semidowndraft Spray Booths: Combining elements of cross-draft and downdraft booths, these systems minimize overspray and contaminants. They are more affordable than downdraft booths and commonly used in smaller workshops.

Portable Spray Booths: These booths are not permanent structures and can be set up and disassembled quickly. They are ideal for small businesses or mobile painting services.

Inflatable Spray Booths: Designed with inflatable walls, these booths create a controlled environment for quick painting jobs. They are suitable for mobile services and require minimal setup.

Maintenance of Manual Spray Booth System

Regular maintenance is essential to ensure the optimal performance of our Manual Spray Booth System. This includes:

Cleaning: Regularly clean the booth, focusing on hard-to-reach areas to prevent dust accumulation. Use a scrubbing brush and a solution of water and paint remover for smaller booths.

Filter Replacement: Change filters regularly to maintain airflow efficiency. For daily use, filters should be replaced every three weeks.

Safety Checks: Conduct daily, weekly, and monthly checks on safety devices and systems to ensure they are functioning correctly.

By following these maintenance practices, our Manual Spray Booth System will continue to provide a safe and efficient coating environment.

As a Manual Spray Booth System Supplier, we are dedicated to delivering high-quality, customizable solutions that meet the diverse needs of industries worldwide. Our Manual Spray Booth System is designed to provide a controlled environment for powder coating, ensuring safety, efficiency, and a superior finish. Whether you are seeking to enhance your existing production capabilities or establish a new line, our systems are engineered to meet your specific requirements. With our expertise and commitment to innovation, we continue to be a trusted partner for businesses looking to optimize their powder coating processes.

Come and contact us to shop! ! !