Content Menu

● Introduction

● What is a Personalized Electrostatic Spray Gun and Control System?

>> Understanding Electrostatic Spray Technology

>> Components of the System

● Advantages of Personalized Electrostatic Spray Guns

>> Enhanced Transfer Efficiency

>> Uniform and High-Quality Coatings

>> Customization for Specific Applications

>> Operator Comfort and Productivity

>> Reduced Maintenance and Downtime

● Key Features of Advanced Control Systems

>> Real-Time Monitoring and Adjustment

>> Automatic Current Limiting

>> Integration with Production Lines

>> Safety Certifications

● Applications of Personalized Electrostatic Spray Guns and Control Systems

>> Automotive Industry

>> Industrial and Agricultural Equipment

>> Consumer Goods and Electronics

>> Powder Coating and Liquid Coating

● Why Choose Our OEM Services for Personalized Electrostatic Spray Guns?

>> Expertise and Innovation

>> Quality and Reliability

>> Comprehensive Support

>> Competitive Pricing

● Frequently Asked Questions (FAQs)

Introduction

In the competitive world of industrial coating, achieving superior finish quality while minimizing waste is paramount. The Personalized Electrostatic Spray Gun and control system has emerged as a cutting-edge solution that transforms traditional spraying processes. By combining advanced electrostatic technology with customizable control systems, manufacturers and brand owners can optimize coating efficiency, improve operator comfort, and reduce operational costs. This article explores the features, benefits, and technological innovations of personalized electrostatic spray guns and their control systems, highlighting how OEM factories like ours in China serve global brands with tailored solutions.

What is a Personalized Electrostatic Spray Gun and Control System?

Understanding Electrostatic Spray Technology

Electrostatic spray guns use high-voltage electrostatic fields to charge coating particles, which are then attracted to the grounded workpiece. This results in a uniform, wrap-around coating that significantly reduces overspray and material waste. The Personalized Electrostatic Spray Gun and control system integrates this technology with customizable components and smart controls to meet specific application needs[5][7].

Components of the System

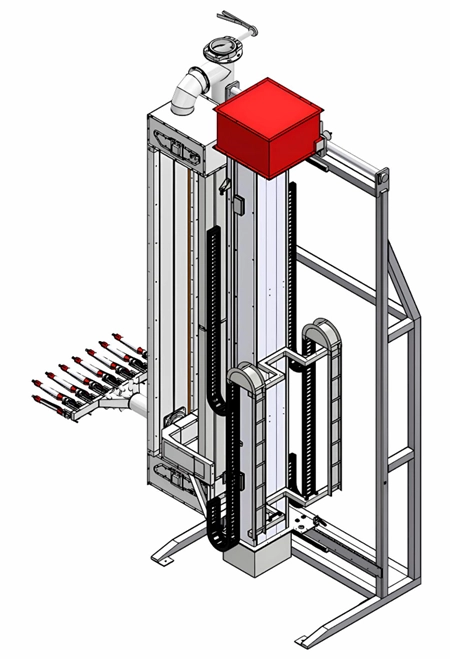

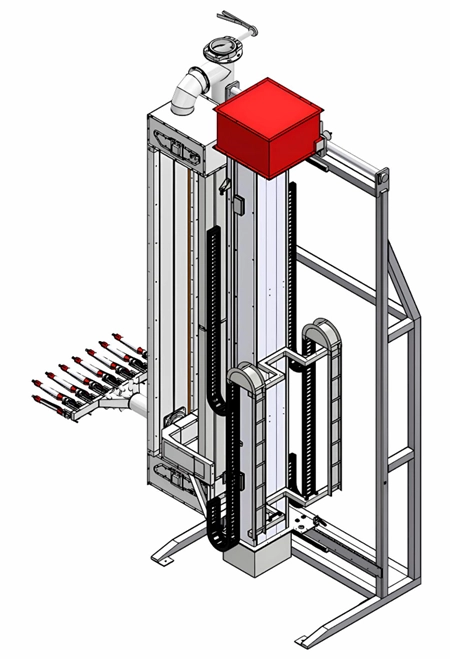

- Electrostatic Spray Gun: The core device that charges the coating particles, designed for durability and ergonomic use.

- High-Voltage Electrostatic Generator: Supplies the necessary voltage to create the electrostatic field.

- Powder or Liquid Supply System: Ensures consistent delivery of coating material.

- Control System: Advanced controllers monitor and adjust voltage, current, and spray parameters in real-time for optimal performance[5].

Advantages of Personalized Electrostatic Spray Guns

Enhanced Transfer Efficiency

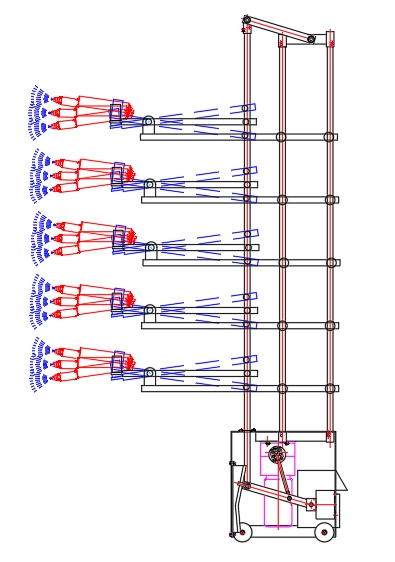

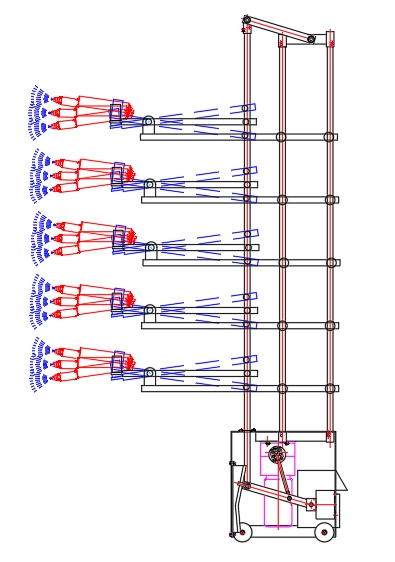

Personalized electrostatic spray guns can achieve transfer efficiencies up to 90%, meaning more coating material adheres to the target surface and less is wasted. This is due to the precise control of the electrostatic charge and optimized spray patterns[5][7].

Uniform and High-Quality Coatings

The electrostatic attraction ensures even distribution of coating particles, including complex shapes and recesses, thanks to the wrap-around effect. This results in smoother finishes and better protection for the coated parts[5].

Customization for Specific Applications

OEM factories provide personalized solutions by adjusting gun parameters, control software, and hardware configurations to suit different coating materials, substrates, and production environments. This flexibility enhances productivity and product quality[1][5].

Operator Comfort and Productivity

Ergonomic designs, such as handle-forward gun bodies and balanced weight distribution, reduce operator fatigue during long production runs. Easy-to-use controls at the fingertips allow quick adjustments without interrupting workflow[3][7].

Reduced Maintenance and Downtime

Durable materials and modular designs in personalized electrostatic spray guns minimize wear and tear. Features like quick-flush fluid passages simplify cleaning, extending equipment life and reducing maintenance costs[3].

Key Features of Advanced Control Systems

Real-Time Monitoring and Adjustment

Modern control systems provide continuous feedback on voltage, current, and spray parameters. This allows operators to fine-tune the process for consistent coating quality and troubleshoot issues promptly[5].

Automatic Current Limiting

This feature controls the electrostatic charge to prevent excessive current flow, improving safety and ensuring optimal powder or paint deposition, especially on complex part profiles[3][7].

Integration with Production Lines

Personalized control systems can be integrated with PLCs and automated production lines, enabling synchronized operation of multiple spray guns and enhancing manufacturing efficiency[3].

Safety Certifications

High-quality control systems comply with FM and CE safety standards, ensuring safe operation in industrial environments[3].

Applications of Personalized Electrostatic Spray Guns and Control Systems

Automotive Industry

Used extensively for coating car bodies and parts, these systems provide durable, uniform finishes that meet stringent quality standards while reducing paint consumption[7][8].

Industrial and Agricultural Equipment

Coating large and complex machinery benefits from the wrap-around effect and high transfer efficiency, improving corrosion resistance and appearance[7].

Consumer Goods and Electronics

Precise coating control allows for delicate finishes on small parts, enhancing product aesthetics and functionality[5].

Powder Coating and Liquid Coating

Both powder and liquid coatings can be applied using personalized electrostatic spray guns, with control systems optimized for each type to maximize efficiency and finish quality[1][5].

Why Choose Our OEM Services for Personalized Electrostatic Spray Guns?

Expertise and Innovation

With years of experience in electrostatic spray technology, our factory specializes in customizing spray guns and control systems tailored to your brand's unique requirements[1][5].

Quality and Reliability

We use high-grade materials and advanced manufacturing processes to ensure our products meet international standards and deliver long-lasting performance[5].

Comprehensive Support

From design consultation to after-sales service, we provide full support to help you integrate personalized electrostatic spray guns seamlessly into your production line[1].

Competitive Pricing

Our efficient production capabilities and supply chain management allow us to offer cost-effective OEM solutions without compromising quality[1].

Frequently Asked Questions (FAQs)

Q1: What does "personalized" mean in the context of electrostatic spray guns?

A1: It refers to customizing the spray gun and control system specifications—such as voltage settings, gun ergonomics, and software controls—to meet the specific needs of different coating applications and production environments[1][5].

Q2: How does the control system improve coating quality?

A2: The control system monitors and adjusts electrostatic parameters in real time, ensuring consistent charge levels and spray patterns, which leads to uniform coatings and reduced waste[5][7].

Q3: Can personalized electrostatic spray guns handle both powder and liquid coatings?

A3: Yes, these systems can be tailored to work with powder coatings or liquid paints, with appropriate adjustments in gun design and control settings[1][5].

Q4: What safety features are included in these systems?

A4: They comply with FM and CE certifications, include automatic current limiting to prevent electrical hazards, and use rugged materials to minimize maintenance risks[3][5].

Q5: How does customization benefit manufacturers and brand owners?

A5: Customization ensures the spray gun system matches the specific coating material, part geometry, and production speed, improving efficiency, reducing costs, and enhancing final product quality[1][5].

[1] https://www.xmsinuowei.com/electrostatic-powder-spray-gun_sp

[2] https://www.graco.com/us/en/in-plant-manufacturing/products/liquid-coating/spray-booth/spray-guns-applicators/electrostatic-paint-spray-guns.html

[3] https://www.nordson.com/en/products/industrial-coating-systems-products/trilogy-electrostatic---spray-systems

[4] https://wldspraybooth.en.made-in-china.com/product/wxcpUNGAYVhI/China-Customization-Electrostatic-Spraying-Powder-Spraying-Powder-Coating-Equipment-Spraying-Coating-Powder-Spraying-Painting-Line.html

[5] https://www.ramseierkoatings.com/electrostatic-spray-gun-and-control-system.html

[6] https://www.scribd.com/document/803743014/TXCA2024%E4%BC%9A%E5%88%8A%E7%94%B5%E5%AD%90%E7%89%88%E4%BC%98%E5%8C%96

[7] https://www.nordson.com/en/about-us/newsroom/industrial-coating-systems-news/nordson-electrostatic-trilogy-spraying-systems---2023-010-03

[8] https://www.sames.com/usa/en/product-trp-501-automatic-electrostatic-spraygun.html

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.