Content Menu

● Understanding Electrostatic Spray Guns

>> What Are Electrostatic Spray Guns?

>> How Do Electrostatic Spray Guns Work?

● Advantages of Electrostatic Spray Guns in Professional Coating Lines

>> Enhanced Transfer Efficiency

>> Superior Coating Quality and Finish

>> Reduced Overspray and Material Waste

>> Environmental Benefits

>> Increased Productivity and Reduced Labor Costs

● Applications of Electrostatic Spray Guns in Various Industries

>> Automotive Industry

>> Furniture and Woodworking

>> Electronics and Appliances

>> Aerospace and Defense

>> Metal Fabrication

● Electrostatic Spray Guns vs. Conventional Spray Guns

● How to Choose the Right Electrostatic Spray Gun for Your Coating Line

>> Consider the Coating Material

>> Determine Desired Voltage and Current Settings

>> Evaluate the Application Environment

>> Maintenance and Ease of Use

>> Budget and Return on Investment

● Operating Tips for Optimal Electrostatic Coating Performance

● Challenges and Considerations

>> Initial Investment and Complexity

>> Limitations with Non-Conductive Materials

>> Safety Precautions

● Future Trends in Electrostatic Coating Technology

● Frequently Asked Questions

Electrostatic spray guns have become an essential tool in professional coating lines due to their efficiency, effectiveness, and environmental benefits. They transform traditional painting and coating processes by offering precise application, reducing waste, and improving coating quality. This article explores why professional coating lines prefer electrostatic spray guns, examining their working principles, advantages, various applications, and how they compare to conventional spray methods. Additionally, it addresses common questions related to the technology.

Understanding Electrostatic Spray Guns

What Are Electrostatic Spray Guns?

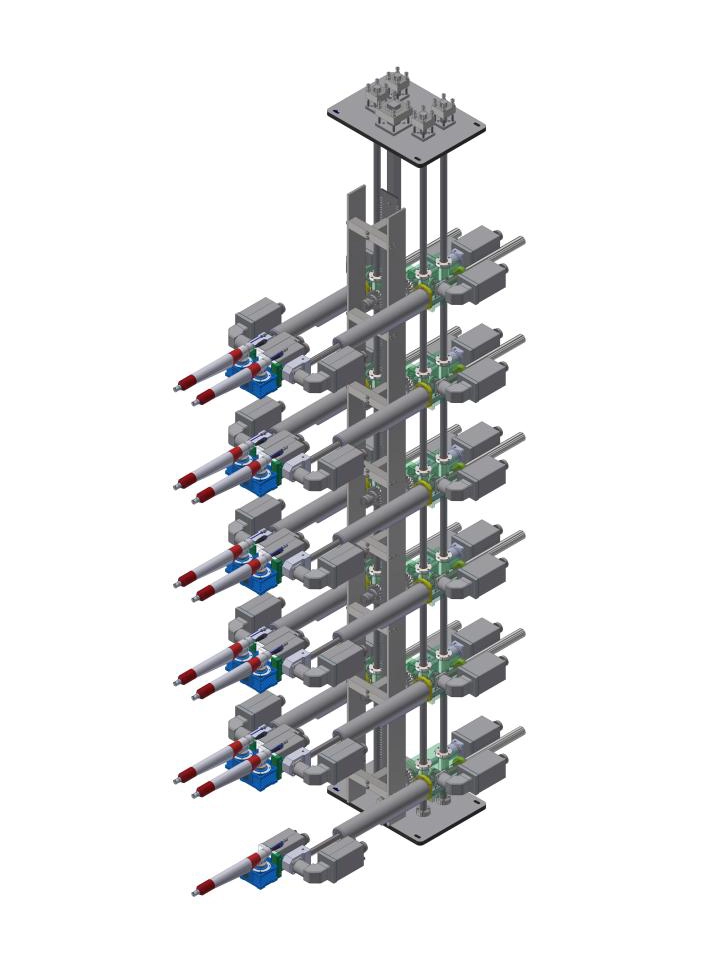

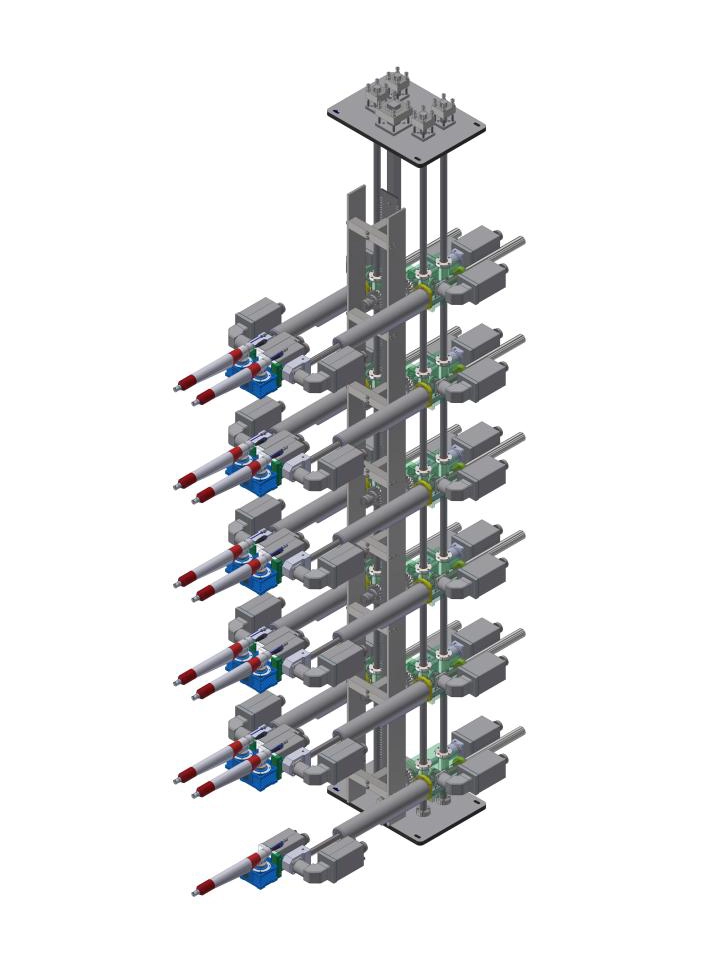

Electrostatic spray guns are devices that apply paint or coating materials by charging the particles electrically. These charged particles are attracted to the grounded workpiece, resulting in a consistent and even coating. The gun imparts a positive or negative charge to the paint particles as they exit the nozzle, which then adhere to surfaces due to electrostatic attraction.

How Do Electrostatic Spray Guns Work?

The gun atomizes the coating material into fine droplets and simultaneously applies an electrical charge to those droplets. The target object, usually grounded, creates an opposite charge that attracts the charged particles. This process dramatically improves transfer efficiency, meaning less overspray and waste.

Advantages of Electrostatic Spray Guns in Professional Coating Lines

Enhanced Transfer Efficiency

One of the most significant advantages is the improved transfer efficiency. Conventional spray guns may have transfer efficiencies as low as 30-40%, meaning most paint misses the target and becomes waste. Electrostatic spray guns can achieve transfer efficiencies of 85% or more by using electrical attraction to draw the paint particles to the surface.

Superior Coating Quality and Finish

Electrostatic spray guns allow for more uniform coating thickness, which leads to a higher quality finish. The charged particles wrap around complex shapes and reach recessed areas where traditional spray methods might struggle. This "wrap-around" effect ensures comprehensive coverage without additional passes.

Reduced Overspray and Material Waste

Due to the higher transfer efficiency, there is a significant reduction in overspray, which means less paint usage and lower material costs. This is economically advantageous for professional coating lines, especially when using expensive coatings or paints.

Environmental Benefits

Reducing overspray also decreases air pollution caused by volatile organic compounds (VOCs) emitted during spraying. Many electrostatic spray guns are designed to be compatible with water-based and low-VOC coatings, contributing to greener manufacturing processes and compliance with environmental regulations.

Increased Productivity and Reduced Labor Costs

Since electrostatic spray guns apply coatings faster and with fewer passes, production speeds increase, reducing labor hours. The precise control minimizes coating defects and rework, boosting overall line efficiency.

Applications of Electrostatic Spray Guns in Various Industries

Automotive Industry

The automotive sector heavily relies on electrostatic spray guns for painting vehicles and components. The technology allows even coatings on complex vehicle shapes, ensuring durability and aesthetic appeal with minimal paint usage.

Furniture and Woodworking

Wood products often require delicate finishing. Electrostatic guns provide smooth and even finish coats on furniture pieces, cabinets, and flooring, enhancing visual appeal and protection.

Electronics and Appliances

Electrostatic coatings are used in electronics to protect devices from moisture, dust, and corrosion. Consistent thin coatings are essential in this sector, making electrostatic guns ideal.

Aerospace and Defense

The aerospace industry demands high-performance coatings for resistance to extreme environments. Electrostatic spray technology ensures reliable protective layers on aircraft components.

Metal Fabrication

For metal parts and fabricated structures, electrostatic spray guns provide corrosion resistance and decorative finishes efficiently, improving product longevity and appearance.

Electrostatic Spray Guns vs. Conventional Spray Guns

| Feature | Electrostatic Spray Guns | Conventional Spray Guns |

| Transfer Efficiency | Up to 85-95% | 30-40% |

| Overspray | Minimal | Significant |

| Coating Uniformity | Superior, even on complex shapes | Uneven in some areas |

| Material Waste | Low | High |

| Environmental Impact | Reduced VOC emissions | Higher VOC emissions |

| Suitable for Complex Shapes | Excellent | Limited |

| Coating Speed | Faster | Slower |

How to Choose the Right Electrostatic Spray Gun for Your Coating Line

Consider the Coating Material

Different coatings like paints, powders, and stains require specific gun types. Ensure your gun is compatible with the coatings used in your process.

Determine Desired Voltage and Current Settings

The voltage applied affects the particle charge and ultimately the coating quality. Professional guns offer adjustable settings to optimize the coating process.

Evaluate the Application Environment

Indoor or outdoor use, ventilation, and grounding possibilities influence spray gun choice. Proper grounding is critical to achieve effective electrostatic attraction.

Maintenance and Ease of Use

Select spray guns that are easy to clean and maintain, especially if your coating line changes materials frequently.

Budget and Return on Investment

Though electrostatic spray guns might have higher upfront costs, their benefits in material savings and productivity often result in faster ROI.

Operating Tips for Optimal Electrostatic Coating Performance

- Always ensure proper grounding of the workpiece.

- Use recommended voltage and air pressure settings.

- Maintain a consistent spray distance to avoid uneven coverage.

- Clean and maintain equipment regularly to avoid clogging or performance degradation.

- Train operators thoroughly on gun handling and safety due to high voltage usage.

Challenges and Considerations

Initial Investment and Complexity

Electrostatic spray guns require a higher initial investment and more technical training than conventional guns. Some processes may need modifications to ensure proper grounding and setup.

Limitations with Non-Conductive Materials

Many non-conductive substrates do not effectively attract charged particles, reducing the benefits of the technology unless a conductive primer is applied.

Safety Precautions

High voltage use necessitates strict safety protocols to avoid shocks or sparks, especially in flammable environments.

Future Trends in Electrostatic Coating Technology

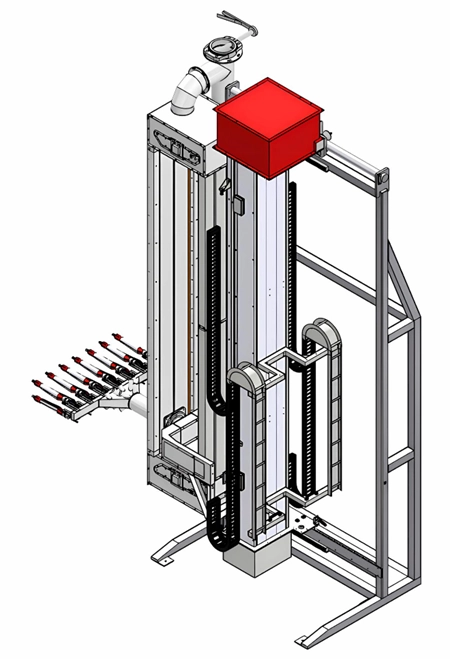

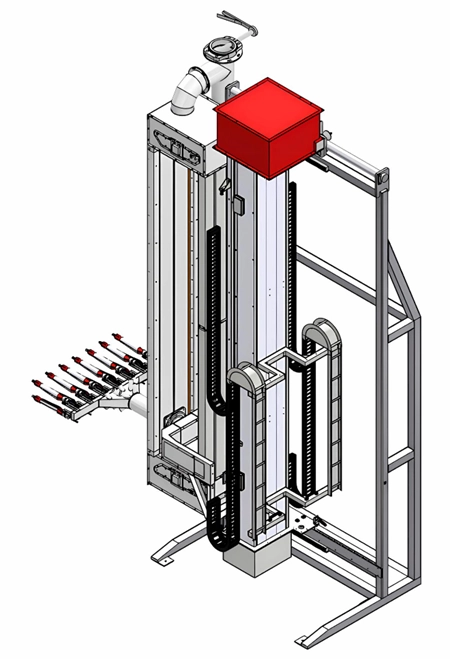

New developments focus on improving atomization quality, reducing energy consumption, and enhancing control systems with digital interfaces. Integration with robotics and automation is growing in professional coating lines for greater precision and consistency.

Frequently Asked Questions

Q1: What makes electrostatic spray guns more efficient than traditional guns?

A1: Electrostatic guns charge the paint particles and attract them to grounded surfaces, minimizing overspray and maximizing transfer efficiency.

Q2: Can electrostatic spray guns be used with powder coatings?

A2: Yes, many electrostatic guns are compatible with powder coatings, providing uniform and high-quality finishes.

Q3: Are electrostatic spray guns safe to use?

A3: Yes, with proper training and adherence to safety protocols, electrostatic spray guns are safe. They operate at high voltage but low current, which reduces shock risks.

Q4: How do I maintain an electrostatic spray gun?

A4: Regular cleaning after use, checking for blockages, inspecting electrical insulation, and proper storage are necessary maintenance steps.

Q5: Can electrostatic spray guns be used on plastic or other non-conductive materials?

A5: They can be used if the substrate is pretreated with a conductive primer so that the charged particles can adhere effectively.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.