Introduction to Automatic Spray Booth Systems

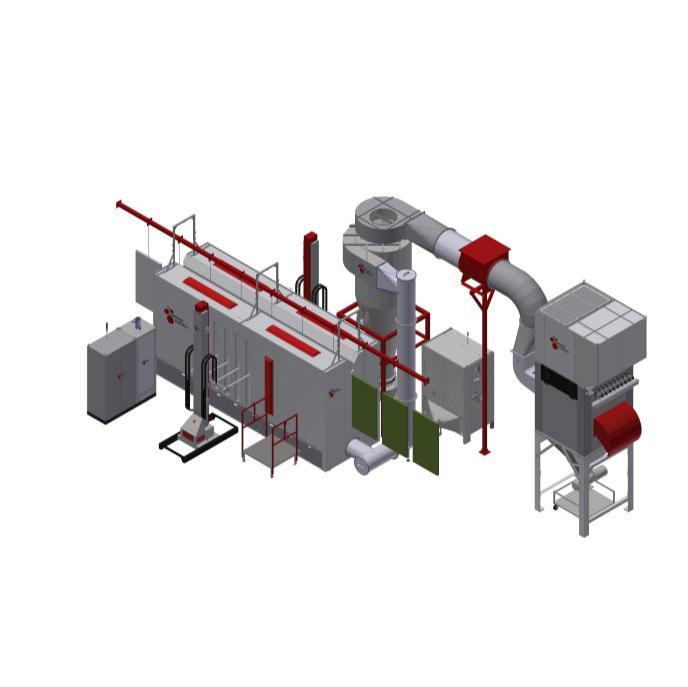

As a renowned automatic spray booth systems manufacturer, we specialize in creating fully integrated powder coating solutions for global clients. Our products are celebrated for their exceptional design, high performance, and stability, earning us a revered reputation worldwide. In this section, we will delve into the world of automatic spray booth systems, exploring their functionality, workflow, advantages, and usage guidelines.

What are Automatic Spray Booth Systems?

Automatic spray booth systems are advanced, high-tech solutions designed to automate the surface treatment process in various industries, including automotive, electronics, and furniture manufacturing. These systems utilize robotics and AI technology to ensure precise and consistent coating applications, significantly enhancing productivity and reducing costs compared to manual methods. As an automatic spray booth systems manufacturer, we focus on delivering systems that not only improve efficiency but also ensure high-quality finishes across diverse product lines.

Workflow of Automatic Spray Booth Systems

The workflow of automatic spray booth systems is streamlined and efficient:

1. Product Loading: Parts are loaded onto a conveyor system that moves them into the spray booth. This conveyor system is customizable to accommodate various product sizes and shapes, ensuring that every item receives an equal amount of paint or coating.

2. Spray Application: Robotic arms equipped with advanced spray nozzles apply coatings according to pre-programmed patterns and speeds. These nozzles are designed for high precision, minimizing overspray and ensuring consistent coverage on all surfaces.

3. Drying and Curing: The parts are then moved to a drying and curing section where they are exposed to controlled temperatures and airflow. This step is crucial for achieving a smooth, durable finish.

4. Quality Inspection: Finally, the finished products undergo quality checks before being unloaded from the system. This ensures that every product meets the required standards, reducing the need for rework and enhancing overall quality.

Advantages of Automatic Spray Booth Systems

As an automatic spray booth systems manufacturer, we highlight several key benefits of these systems:

Improved Consistency: Manual spray painting relies heavily on operator skill, leading to variability. With automatic spray booth systems, the process is controlled by robotics, which guarantees that each part receives an identical finish. Sensors and AI technology ensure that the spray pattern is adjusted in real-time, eliminating defects such as runs, drips, or uneven layers.

Speed and Efficiency: An automatic spray booth can operate at speeds far beyond what manual operators can achieve. The conveyor systems used in these booths allow continuous painting, where parts move through the booth without stopping, ensuring a steady production rate. This leads to significant time savings, especially for high-volume operations such as automotive or electronics manufacturing.

Reduced Waste and Cost: One of the major advantages of automatic spray booth systems is their ability to reduce waste. Transfer efficiency, or the amount of paint that actually adheres to the surface versus what is lost to overspray, is much higher in automated systems. This translates into less paint used per part, lowering material costs and contributing to a more environmentally friendly operation.

Enhanced Worker Safety: Paint and coating materials often contain hazardous chemicals that can pose health risks to workers. Automatic spray booth systems significantly reduce human exposure to these harmful substances. Workers are not directly involved in the spray painting process, as the machinery does all the work inside a contained environment with proper ventilation.

Using Automatic Spray Booth Systems: Safety and Operational Considerations

While automatic spray booth systems offer numerous advantages, there are important considerations for safe and effective operation:

1. Safety Measures: Ensure proper ventilation to prevent the buildup of flammable vapors and maintain a safe working environment. Install fire detection and suppression systems, and use explosion-proof electrical components. Regular maintenance of ventilation systems and filters is crucial to prevent malfunctions and ensure optimal performance.

2. Regular Maintenance: Regularly inspect and maintain electrical equipment, conveyor systems, and robotic arms to prevent malfunctions and ensure optimal performance. This includes monitoring the ventilation system to ensure proper airflow is maintained through the booth.

3. Training and Compliance: Ensure all personnel are trained in operating the system and adhere to local safety regulations and standards. This includes understanding the proper use of personal protective equipment (PPE) and following safety protocols for handling flammable materials.

4. Environmental Considerations: Implement sustainable practices by reducing waste and using eco-friendly coatings when possible. Automatic spray booth systems can be retrofitted to accommodate low-VOC paints and water-based coatings, ensuring compliance with environmental standards while maintaining high-quality finishes.

Choosing the Right Automatic Spray Booth System

As an automatic spray booth systems manufacturer, we understand that selecting the right system for your needs is crucial. Here are some factors to consider:

Production Volume: Determine if you need a synchronous, non-synchronous, single station, or continuous booth based on your production volume and frequency.

Product Dimensions: Ensure the booth is designed to accommodate the size and shape of your products. Customizable conveyor systems allow for flexibility in handling diverse product lines.

Desired Finish Quality: Consider the level of precision and consistency required for your coatings. Automatic spray booth systems can be programmed to achieve specific finishes, from smooth automotive coatings to durable aerospace components.

Future Trends in Automatic Spray Booth Systems

The future of automatic spray booth systems is marked by innovation in automation, digitalization, and eco-friendly solutions. As industries demand higher-quality finishes, faster production rates, and reduced environmental impact, automatic spray booth systems manufacturers are integrating Industry 4.0 and IoT technologies. These advancements enable real-time data analysis, predictive maintenance, and optimized spray painting processes, ensuring consistent finishes and minimizing waste.

In conclusion, automatic spray booth systems are a game-changer for industries requiring precise and efficient surface treatment. As a leading automatic spray booth systems manufacturer, we are committed to providing cutting-edge solutions that enhance productivity, safety, and environmental sustainability. Whether you're looking to upgrade your existing facilities or integrate new technology into your production line, our expertise and products are designed to meet your specific needs and exceed your expectations.

Contact Us

If you're interested in learning more about how automatic spray booth systems can transform your manufacturing process, please don't hesitate to reach out. Our team of experts is ready to guide you through the selection and implementation process, ensuring that you find the perfect solution for your business. Contact us now!

About Us

With decades of experience in the industry, we pride ourselves on being a trusted automatic spray booth systems manufacturer. Our mission is to innovate and deliver high-quality products that set new standards in performance and reliability. Join us in embracing the future of surface treatment technology.