Content Menu

● Introduction to Powder Coating and Precision Demands

● Understanding High-Precision Powder Coating

>> Why High-Precision Matters

● Key Features of a High-Precision Powder Spray Gun Unit

>> 1. Consistency and Uniformity of Film Thickness

>> 2. Advanced Electrostatic Technology

>> 3. Adjustable Nozzle and Volume Controls

>> 4. Ergonomics and Ease of Handling

>> 5. Minimal Overspray and Effective Powder Recovery

● Types of Spray Gun Units

>> Manual vs. Automatic Spray Guns

>> Corona vs. Tribo Charging Guns

● Criteria for Selecting the Best Spray Gun Unit

>> Powder Output and Consistency

>> Adjustable Controls and Versatility

>> Advanced Charging and Atomization

>> Quality Construction and Build Materials

>> Ease of Cleaning and Maintenance

>> Digital Integration and Monitoring

● Top Candidates: Industry-Leading High-Precision Powder Spray Guns

>> 1. Gema OptiFlex Pro Series

>> 2. Wagner PEM-X1

>> 3. Nordson Encore HD

>> 4. Sames Kremlin Inocoat

>> 5. Eastwood Elite PCS-1000

● How to Use a High-Precision Powder Spray Gun Unit Effectively

>> Workspace Preparation

>> Optimizing Gun Settings

>> Application Techniques

>> Troubleshooting Common Issues

● Maintenance and Longevity Tips for Your Spray Gun Unit

● Precision Powder Coating in Industrial Sectors

>> Automotive and Transportation

>> Electronics and Medical Devices

>> Aerospace and Defense

>> Artisanal and Decorative Applications

● Advanced Innovations in Powder Coating Spray Guns

● Frequently Asked Questions

>> Q1: What is the primary difference between a high-precision powder spray gun and a standard spray gun?

>> Q2: How does powder coating with a high-precision spray gun reduce waste?

>> Q3: Can a high-precision unit handle multiple types of powder or colors?

>> Q4: What maintenance does a high-precision powder spray gun require?

>> Q5: Is it possible to retrofit existing powder coating systems with high-precision spray guns?

Powder coating technology has revolutionized the way industries and artisans protect and beautify metal surfaces. At the heart of this technology lies the spray gun unit, a tool engineered to deliver fine, consistent coatings for both aesthetic and protective purposes. Selecting the best spray gun unit for high-precision powder coating applications requires a nuanced understanding of the science behind powder coating, the various types of spray gun units, and the factors that influence performance. In this comprehensive guide, we'll explore the critical aspects that define high-precision powder coating, break down the top criteria for choosing the ideal spray gun, and review top products and innovations in the field. We will also answer pressing questions that users frequently encounter and provide a concise summary at the end.

Introduction to Powder Coating and Precision Demands

Powder coating is an environmentally friendly, durable, and aesthetically versatile method for finishing metal and other surfaces. Unlike liquid paint, powder coating relies on an electrically charged powder applied to grounded parts. The powder adheres via electrostatic attraction and is then cured to form a hard, smooth finish.

While powder coating is prized for its robustness and versatility, some applications—such as electronics, automotive parts, aerospace components, and designer fixtures—demand a level of precision unattainable through general-purpose equipment. In these contexts, the right spray gun unit becomes critical. Precision powder coating requires consistency in film thickness, minimal overspray, sharp edges, and flawless finish—all of which rely on equipment that delivers unparalleled control.

Understanding High-Precision Powder Coating

Why High-Precision Matters

High-precision powder coating is essential for components where tight tolerances and meticulous finish are not mere aesthetic choices, but operational requirements. Some reasons for demanding such precision include:

- Functionality: Electrical components and machinery parts often require exact coating thicknesses for effective insulation or movement.

- Aesthetics: Visible surfaces must be free of blemishes, "orange peel" texture, and uneven coating, especially for luxury goods.

- Durability: Even and uniform coatings shield against corrosion, wear, and environmental factors more efficiently.

- Cost and Waste Reduction: Precision application means less wasted powder and reduced post-processing.

Key Features of a High-Precision Powder Spray Gun Unit

1. Consistency and Uniformity of Film Thickness

A top-tier spray gun unit must ensure reliable film thickness with every pass, avoiding uneven spots and run-off. This is achieved through accurate control of powder output and optimal atomization technology.

2. Advanced Electrostatic Technology

A premium unit should employ advanced charging technology, such as high-voltage cascade modules and optimized electrode designs. These features ensure each powder particle is properly charged for uniform adhesion.

3. Adjustable Nozzle and Volume Controls

Precision requires fine-tuning. A quality spray gun offers easily adjustable nozzles, powder flow, and spray pattern controls to accommodate different substrates, geometries, and detail work.

4. Ergonomics and Ease of Handling

High-precision work often means extended hours of operation, meticulous component coating, and intricate techniques. Ergonomically designed guns reduce user fatigue and allow for steadier, more controlled application.

5. Minimal Overspray and Effective Powder Recovery

Reducing overspray is fundamental in high-value projects. The best units are designed to minimize waste, often incorporating efficient powder recovery systems that maintain cleanliness and reduce costs.

Types of Spray Gun Units

Manual vs. Automatic Spray Guns

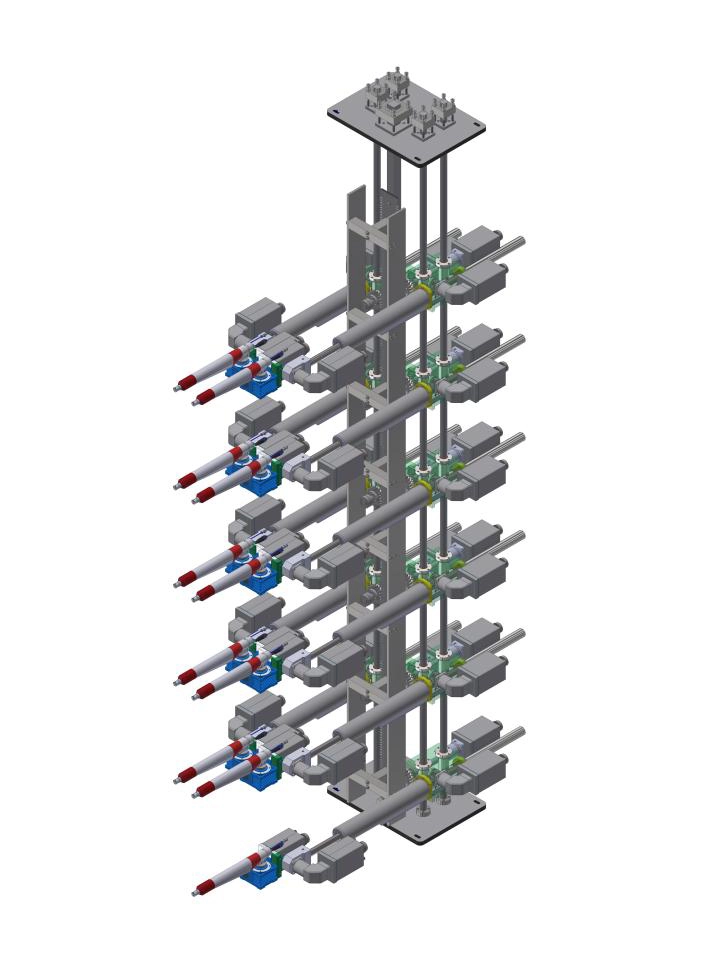

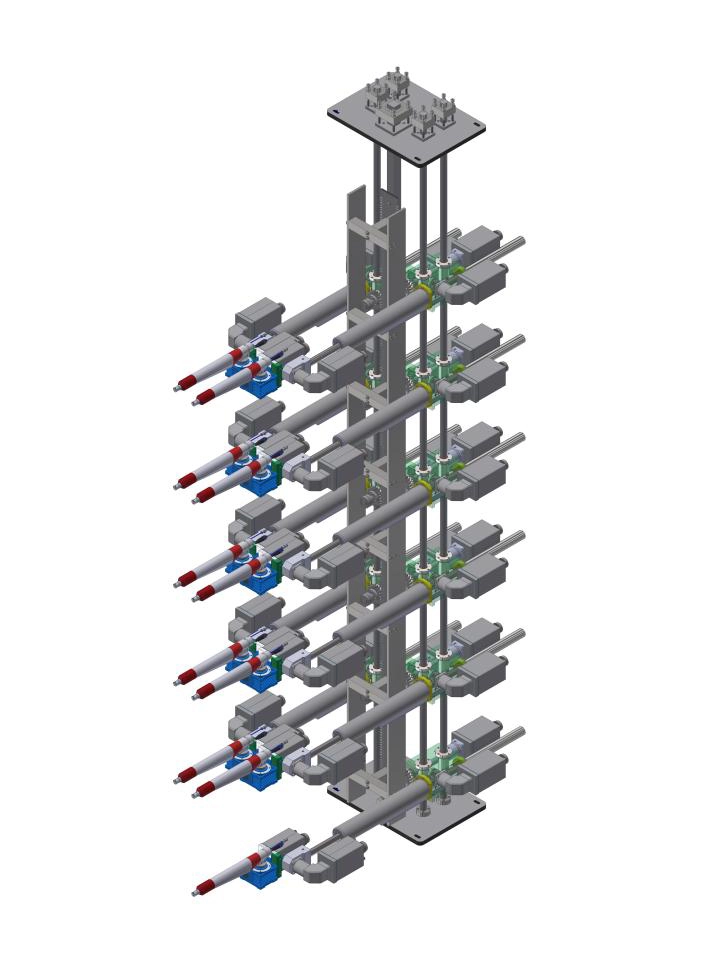

- Manual Powder Spray Guns: Ideal for craftsmen and smaller production runs where adaptability and human control are essential. Offer direct manipulation for targeting delicate areas.

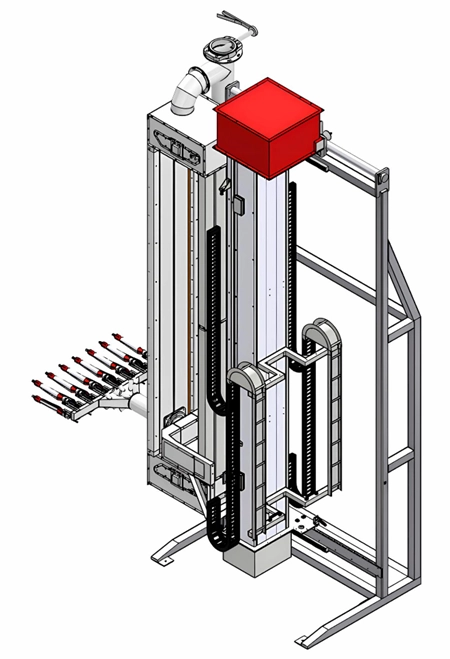

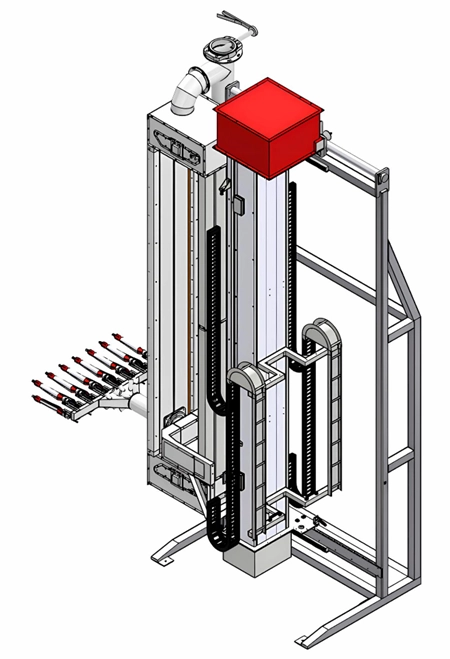

- Automatic Spray Guns: Best suited for large-scale manufacturing, these guns can be programmed for consistency and speed. High-precision automatic systems are vital for industries requiring mass production with tight tolerances.

Corona vs. Tribo Charging Guns

- Corona Guns: Use high-voltage electrodes to charge powder particles electrostatically. Typically, they allow for broader application but may be susceptible to Faraday cage effects.

- Tribo Guns: Rely on frictional charging (powder rubs against the gun's interior). These guns provide excellent penetration in complex geometries and reduce some of the challenges associated with corona discharge in intricate parts.

Criteria for Selecting the Best Spray Gun Unit

Powder Output and Consistency

The ability to deliver a consistent powder flow—even at low volumes—is non-negotiable for precise applications. Any variability can affect not just aesthetics but essential functional performance.

Adjustable Controls and Versatility

Operators must easily adjust the spray pattern, flow rate, and charge settings. This flexibility ensures the same gun can handle multiple part types, materials, and powder formulations.

Advanced Charging and Atomization

Units with superior charging modules create a stronger and more uniform electrostatic field, ensuring powder wraps around complex parts for full coverage—even on hidden surfaces or sharp angles.

Quality Construction and Build Materials

Durability is vital. Units should feature corrosion-resistant components and robust housings, ensuring reliable operation in industrial environments.

Ease of Cleaning and Maintenance

Quick-change nozzles, smooth powder pathways, and easy-to-clean designs help prevent cross-contamination and down-time between color changes or projects.

Digital Integration and Monitoring

High-precision modern units may incorporate digital readouts, programmable settings, and integration with factory automation systems for real-time monitoring and quality assurance.

Top Candidates: Industry-Leading High-Precision Powder Spray Guns

When precision matters, several leading manufacturers consistently deliver quality and innovation in powder coating equipment. Below are five top contenders, each with strengths suited to various precision applications.

1. Gema OptiFlex Pro Series

Key Benefits:

- Digital control system with up to 100,000 volts of charging for extremely fine application.

- Adaptive nozzle technology allowing fast swaps between different spray patterns.

- Consistent powder transfer efficiency and rapid color change capabilities.

- Ergonomically engineered for minimal operator fatigue.

Ideal For: Automotive refinishing, electronics, and intricate frames that require sharp details.

2. Wagner PEM-X1

Key Benefits:

- Patented cascade technology for uniform particle charging.

- Precise control of powder output with ultra-fine application capabilities.

- Balanced gun weight and grip for prolonged use in detail-oriented work.

- Exceptional penetration in complex part geometries.

Ideal For: Aerospace components, luxury goods, and large-scale industrial parts with tight tolerances.

3. Nordson Encore HD

Key Benefits:

- High density, dense-phase powder delivery for low-velocity, high-precision application.

- In-gun voltage control with digital display.

- Consistent film thickness and reduced overspray.

- Quick color change design.

Ideal For: Medical device coatings, precision electronics, and decorative finishes where uniformity is key.

4. Sames Kremlin Inocoat

Key Benefits:

- Soft-spray technology for reduced bounce and minimal powder loss.

- Integrated smart controls with job memory.

- Tribo compatible, making it suitable for difficult geometries.

- Lightweight design and premium build quality.

Ideal For: OEM manufacturing, fine metalwork, and complex-shaped parts.

5. Eastwood Elite PCS-1000

Key Benefits:

- Affordable precision for small workshops and boutique shops.

- Consistent output, easy controls, and durable construction.

- Suitable for low- to mid-volume high-precision work.

Ideal For: Artisans, restorers, and prototype shops handling intricate custom jobs.

How to Use a High-Precision Powder Spray Gun Unit Effectively

Workspace Preparation

- Ensure the workspace is clean, dust-free, and humidity controlled.

- Use proper personal protective equipment (PPE), including respirators and gloves.

Optimizing Gun Settings

- Adjust powder output, voltage, and spray pattern before starting.

- Test the settings on sample pieces or scrap parts to avoid waste.

Application Techniques

- Maintain consistent gun-to-part distance, usually 6-12 inches, for uniform coverage.

- Move the gun smoothly, overlapping each pass by around 50% for even film build.

- Focus on complex or recessed areas first to avoid excessive build-up.

Troubleshooting Common Issues

- Orange Peel Effect: May result from improper gun distance, excessive powder, or incorrect temperature.

- Faraday Cage Effect: Adjust voltage or use a tribo gun for deep recesses and sharp corners.

- Uneven Coverage: Check powder flow, ensure grounding, and regulate hand movement.

Maintenance and Longevity Tips for Your Spray Gun Unit

- Clean all powder passages and nozzles after every use to prevent clogging.

- Store guns in a dry, clean location.

- Service electrostatic modules and check wiring regularly.

- Replace consumable parts (nozzles, electrodes) as per the manufacturer's recommendations.

Precision Powder Coating in Industrial Sectors

Automotive and Transportation

Use of high-precision powder coating allows for flawless finishes on visible car components, intricate parts for electric vehicles, and protection of exposed metals.

Electronics and Medical Devices

Thin, even coatings are essential for insulation, aesthetics, and bio-compatibility in sensitive equipment.

Aerospace and Defense

Consistency in coverage directly impacts component durability, safety, and performance under extreme conditions.

Artisanal and Decorative Applications

Fine, even coverage elevates finishes on lamps, furniture, and luxury hardware, meeting demanding consumer expectations.

Advanced Innovations in Powder Coating Spray Guns

Modern powder spray units incorporate several state-of-the-art technologies to further enhance precision:

- Smart Feedback Systems: Sensors in the gun body provide real-time feedback on application metrics.

- Data Logging and Analytics: Integration with software enables process optimization through historical data analysis.

- Customizable Spray Profiles: Operators can save and recall settings, ensuring consistency across production runs.

- Energy-Efficient Modes: Reduce power consumption during idle periods without sacrificing performance.

These innovations are rapidly advancing the possibilities for powder coating quality, speed, and repeatability.

Frequently Asked Questions

Q1: What is the primary difference between a high-precision powder spray gun and a standard spray gun?

A: High-precision spray guns offer more accurate control over powder output, particle charging, and spray pattern. They are optimized to deliver consistent, thin, uniform coatings necessary for critical applications, whereas standard guns may be more suited for less demanding finishes.

Q2: How does powder coating with a high-precision spray gun reduce waste?

A: These guns minimize overspray due to their fine atomization and superior powder charging, ensuring more powder adheres to the target part. This, combined with efficient recovery systems, results in less powder lost to the environment and less need for post-coating cleanup.

Q3: Can a high-precision unit handle multiple types of powder or colors?

A: Yes, most modern high-precision spray guns are designed for rapid color changes and can accommodate different powder types with minimal cross-contamination, provided they are properly cleaned and maintained.

Q4: What maintenance does a high-precision powder spray gun require?

A: Routine maintenance includes cleaning powder pathways and nozzles, checking electrical connections, inspecting media lines, replacing worn parts, and regular software or firmware updates if digital controls are present.

Q5: Is it possible to retrofit existing powder coating systems with high-precision spray guns?

A: In many cases, yes. As long as the powder feed, control systems, and booth infrastructure are compatible, upgrading to a high-precision gun can enhance the capabilities of an existing system. Always consult manufacturer guidelines for compatibility.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.