Content Menu

● Introduction

● Understanding Powder Coating Systems

>> What is Powder Coating?

>> Components of a Powder Coating System

● The Spray Gun Unit: Definition and Importance

>> What is a Spray Gun Unit?

>> Importance in the Powder Coating Process

● Types of Spray Gun Units in Powder Coating

>> Corona Spray Guns

>> Tribo Spray Guns

>> Hybrid Systems

● Smart Technologies in Spray Gun Units

>> Integration of Sensors

>> Automated Adjustment and Feedback Systems

>> Connectivity and Data Analytics

● Benefits of Smart Spray Gun Units in Powder Coating Systems

>> Enhanced Coating Quality

>> Increased Powder Transfer Efficiency

>> Improved Operational Efficiency

>> Predictive Maintenance and Reduced Downtime

● Installation and Calibration of Spray Gun Units

>> Proper Installation Considerations

>> Calibration Procedures

● Maintenance and Troubleshooting of Spray Gun Units

>> Routine Maintenance

>> Common Issues and Solutions

● Future Trends in Spray Gun Units for Smart Powder Coating

>> AI and Machine Learning Integration

>> Advanced Materials for Electrodes and Nozzles

>> Miniaturization and Portability

>> Enhanced Environmental Sustainability

● Conclusion

● Common Questions and Answers

Introduction

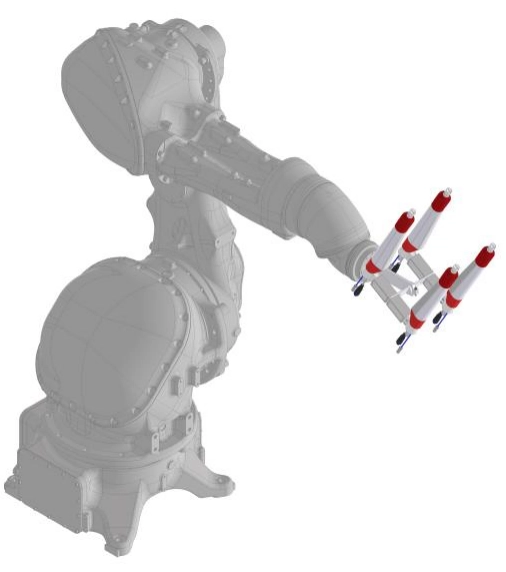

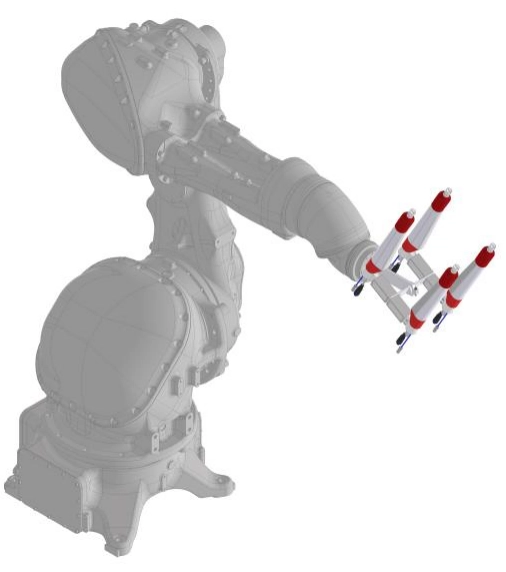

In the realm of industrial surface finishing, powder coating has emerged as a superior technique, offering durability, environmental benefits, and aesthetic appeal. With the advent of Industry 4.0, the integration of smart technologies into powder coating processes has become essential to enhance efficiency, quality, and repeatability. Among the various components of a smart powder coating system, spray gun units play a pivotal role. They are the interface between the powder delivery system and the workpiece, determining the coating quality and operational efficiency directly.

This article explores the crucial role of spray gun units in smart powder coating systems. It covers the types of spray gun units, their working principles, the integration of smart technologies, and how these innovations transform the powder coating industry. The discussion will also delve into maintenance, troubleshooting, and future trends to provide a comprehensive view.

Understanding Powder Coating Systems

What is Powder Coating?

Powder coating is a finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto a grounded metal surface. Once applied, the coated piece is baked in an oven where the powder melts and forms a continuous, durable, and protective layer.

Components of a Powder Coating System

A typical powder coating system includes:

- Powder supply units (hoppers or feeders)

- Spray gun units

- Grounding equipment

- Control units

- Curing ovens

Among these, the spray gun unit is the critical component that manages the application of powder onto the surface.

The Spray Gun Unit: Definition and Importance

What is a Spray Gun Unit?

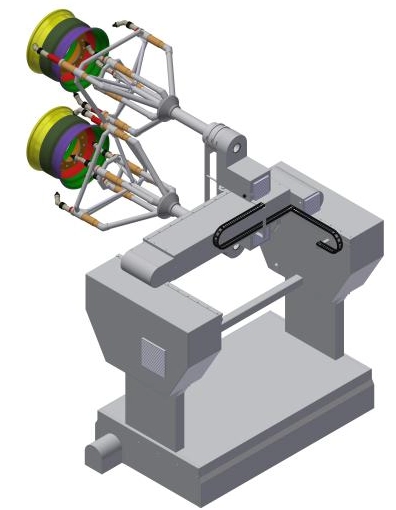

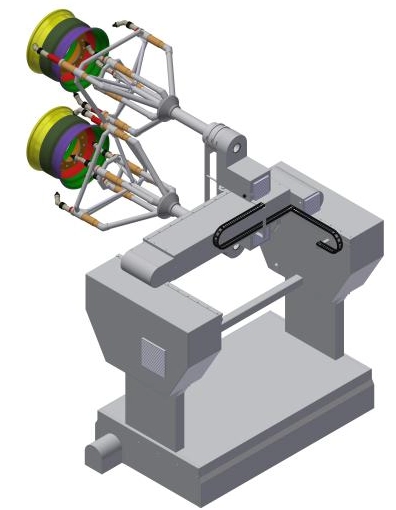

A spray gun unit in powder coating systems is a device that delivers powder particles to the target surface using an electrostatic charge. The gun creates an electrostatic field that charges the powder, ensuring particles adhere uniformly to the workpiece. Spray guns vary in design but generally consist of a powder feeding mechanism, a charging electrode, an air cap nozzle, and controls for powder flow and charge levels.

Importance in the Powder Coating Process

The spray gun unit influences:

- Coating uniformity and thickness

- Powder transfer efficiency (how much powder reaches and sticks to the surface)

- Reduction of overspray and powder waste

- The quality and speed of the coating process

A well-functioning spray gun unit is vital to achieving high-quality finishes and cost-effective operations.

Types of Spray Gun Units in Powder Coating

Corona Spray Guns

Corona spray guns use a high-voltage corona discharge to impart an electrostatic charge to the powder particles. This technology is widely used due to its simplicity and effectiveness for standard applications. The powder is fluidized and then drawn towards the electrode, where it becomes charged and sprayed.

Tribo Spray Guns

In tribo spray guns, powder particles are charged through friction by rubbing against a specially coated or designed surface inside the gun. This method relies on the triboelectric effect, and it is particularly effective for certain powder materials and complex workpiece shapes.

Hybrid Systems

Some modern spray guns combine corona and tribo charging technologies to leverage the advantages of both. They provide enhanced control over charging and application, suitable for sophisticated production requirements.

Smart Technologies in Spray Gun Units

Integration of Sensors

Sensor technology is crucial in smart spray gun units. Sensors can monitor parameters such as powder flow rate, charge level, air pressure, voltage, and temperature in real-time. This data allows for precise control and adjustment during the coating process, minimizing defects and waste.

Automated Adjustment and Feedback Systems

Smart spray guns are integrated into automated systems that adjust operational parameters dynamically based on sensor feedback. For example, if the powder flow decreases or the electrostatic charge fluctuates, the system can correct settings instantly to maintain consistent coating quality.

Connectivity and Data Analytics

Modern guns are equipped with connectivity features enabling communication with central control systems or the Internet of Things (IoT) platforms. This allows operators to track performance, predict maintenance needs, and optimize production processes using big data analytics and machine learning.

Benefits of Smart Spray Gun Units in Powder Coating Systems

Enhanced Coating Quality

Smart spray guns provide uniform powder distribution and consistent charge, leading to smooth, defect-free finishes. This reduces the frequency of rework and improves customer satisfaction.

Increased Powder Transfer Efficiency

By precise control of powder delivery and electrostatic charging, smart units reduce overspray and powder wastage, significantly cutting material costs and environmental impact.

Improved Operational Efficiency

Automated controls and real-time monitoring streamline the coating process, reduce operator intervention, and enable higher throughput.

Predictive Maintenance and Reduced Downtime

The integration of diagnostic sensors and IoT connectivity allows for predictive maintenance. Issues are detected early, preventing unplanned downtime that can disrupt production schedules.

Installation and Calibration of Spray Gun Units

Proper Installation Considerations

Correct installation ensures optimal spray pattern and powder flow. The gun must be positioned with an appropriate spray distance and angle for the target surface. Grounding and electrical connections must meet safety and performance standards.

Calibration Procedures

Calibration involves adjusting parameters such as powder feed rate, voltage level, and airflow to match the workpiece specifications. Regular calibration is critical to maintain consistent coating quality over time.

Maintenance and Troubleshooting of Spray Gun Units

Routine Maintenance

Regular cleaning of powder feed passages, electrodes, and air caps prevents clogging and ensures consistent performance. Components like nozzles and electrodes may require periodic replacement due to wear.

Common Issues and Solutions

- Powder flow inconsistency: Clean or replace clogged feed lines; check for proper powder supply.

- Weak electrostatic charge: Inspect and clean electrodes; verify voltage settings.

- Uneven coating or spray patterns: Adjust gun angle, spray distance, or air pressure; replace worn nozzles.

- Excessive overspray: Check grounding of workpieces; fine-tune powder flow and voltage.

Future Trends in Spray Gun Units for Smart Powder Coating

AI and Machine Learning Integration

The future of spray gun units includes AI algorithms that learn from operational data to optimize settings autonomously, predict failures earlier, and guide operators with decision support tools.

Advanced Materials for Electrodes and Nozzles

Research into durable, anti-wear materials aims to extend the lifespan of gun components, reducing maintenance frequency and improving reliability.

Miniaturization and Portability

Development of compact, portable smart spray guns can enable on-site powder coating in remote or constrained environments, expanding the versatility of the technology.

Enhanced Environmental Sustainability

Innovations will focus on reducing powder waste further, lowering energy consumption during coating, and developing eco-friendly powder formulations compatible with smart guns.

Conclusion

Spray gun units are central to the effectiveness of smart powder coating systems. Their role in material delivery, electrostatic charging, and coating uniformity dictates the overall quality and efficiency of the powder coating process. The advancement from traditional manual guns to smart, sensor-integrated, and AI-enhanced units has revolutionized surface finishing by enabling precise control, reduced waste, and predictive maintenance. As the industry evolves, ongoing innovations promise even smarter, more reliable, and environmentally conscious powder coating systems, making spray gun technology a cornerstone of modern industrial coatings.

Common Questions and Answers

1. What factors influence the efficiency of a spray gun unit in powder coating?

Factors include powder flow rate, charging voltage, air pressure, gun-to-workpiece distance, and environmental conditions. Optimizing these ensures maximum transfer efficiency and uniform coating.

2. How do corona and tribo spray guns differ in powder charging?

Corona guns use a high-voltage corona discharge to charge powder particles, while tribo guns rely on the frictional (triboelectric) effect between powder and the gun's internal surfaces.

3. Why is sensor integration important in smart spray guns?

Sensors provide real-time data on critical parameters, allowing automatic adjustments, reducing defects, minimizing waste, and enabling predictive maintenance.

4. Can spray gun units be used for coatings on non-metal substrates?

Typically, powder coating requires conductive substrates to hold the electrostatic charge; however, special grounding methods and powders enable coating of some non-metal materials.

5. What maintenance practices extend the life of spray gun units?

Regular cleaning of nozzles and electrodes, inspection and replacement of worn parts, and calibration of operational parameters are essential for long-term performance.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.