Introduction to Electrostatic Spray Gun Systems

As a pioneering Hong Kong-based company with over 38 years of experience in researching and innovating spraying equipment, we specialize in creating fully integrated powder coating solutions for the global market. Our products are renowned for their exceptional design, high performance, and stability, earning us a revered reputation among clients worldwide. At the heart of our offerings is the electrostatic spray gun system, a cutting-edge technology that revolutionizes the powder coating process.

What is an Electrostatic Spray Gun System?

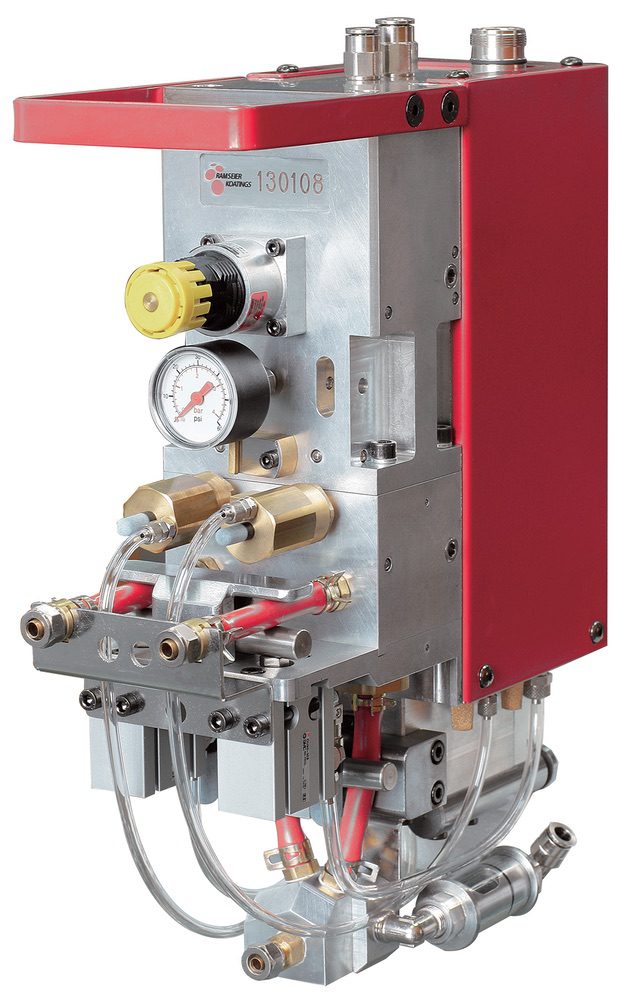

An electrostatic spray gun system is a sophisticated device designed to enhance the efficiency and quality of powder coating applications. It consists of several key components, including the electrostatic spray gun, a high-voltage electrostatic generator, and powder supply system. These components work in harmony to ensure a uniform and efficient coating process.

Components of an Electrostatic Spray Gun System

1. Electrostatic Spray Gun: This is the core component of the system, responsible for charging the powder particles. It uses a high-voltage electrostatic field to attract the powder to the grounded workpiece, ensuring a smooth and even coating.

2. High-Voltage Electrostatic Generator: This device generates the high voltage necessary for creating the electrostatic field. It is crucial for maintaining the optimal charge on the powder particles.

3. Powder Supply System: This includes powder hoppers and feeders that ensure a consistent supply of powder to the spray gun. The system is designed to maintain a precise flow rate, which is essential for achieving the desired coating thickness.

4. Control System: Our smart control and data management system allows for precise monitoring and adjustment of the electrostatic spray gun system. It optimizes performance by analyzing voltage needs, troubleshooting issues, and providing real-time feedback.

Operating Principle of an Electrostatic Spray Gun System

The electrostatic spray gun system operates based on the principle of electrostatic attraction. The powder particles are charged negatively as they pass through the spray gun, while the workpiece is grounded, creating a positive charge. This difference in charge causes the powder particles to be attracted to the workpiece, ensuring a high transfer efficiency with minimal waste. The process involves:

Corona Discharge: A high-voltage discharge at the tip of the spray gun generates a corona, which charges the powder particles.

Electrostatic Field: The charged particles are then directed towards the workpiece by the electrostatic field, ensuring they adhere evenly.

Wrap-Around Effect: The charged particles can change direction in mid-air, allowing them to coat complex shapes and wrap around objects, increasing the surface area covered.

Features of an Electrostatic Spray Gun System

1. High Transfer Efficiency: The electrostatic spray gun system achieves transfer efficiencies of up to 90%, significantly reducing waste and saving materials.

2. Uniform Coating: The electrostatic attraction ensures a smooth, even coating, which is crucial for achieving high-quality finishes.

3. Environmental Benefits: By minimizing overspray and reducing the amount of coating material needed, the system lowers VOC emissions and environmental impact.

4. Increased Productivity: The efficiency of the electrostatic spray gun system allows for faster production cycles, making it ideal for high-volume applications.

Applications of an Electrostatic Spray Gun System

The electrostatic spray gun system is versatile and widely used across various industries, including:

Automotive Parts: For coating car components such as wheels and body parts.

Furniture and Wood Products: Enhancing the finish of wood furniture with a durable, smooth coat.

Sheet Metal and Appliances: Providing protective and decorative coatings for metal products.

Construction and Engineering Machinery: Applying durable coatings to machinery parts for protection against corrosion.

In conclusion, our electrostatic spray gun system is a comprehensive solution designed to optimize powder coating processes. With its advanced technology and numerous benefits, it is an indispensable tool for industries seeking high-quality finishes while minimizing environmental impact. Whether you are looking to enhance production efficiency, reduce waste, or achieve superior coating quality, our electrostatic spray gun system is the ideal choice.

Additional Solutions for Enhanced Efficiency

To further enhance the efficiency of your electrostatic spray gun system, we offer complementary products such as:

Automatic Spray Booth Systems: Designed for high-volume production, these systems automate the coating process, ensuring consistency and speed.

Manual Spray Booth Systems: Suitable for smaller-scale operations or specialized coatings, these systems provide flexibility and control.

Reciprocators and Automation: These components automate the movement of the spray gun, ensuring uniform coverage and reducing labor costs.

Powder Management Center and Hoppers: Essential for maintaining a consistent powder supply, these systems optimize powder usage and minimize waste.

By integrating these solutions with our electrostatic spray gun system, you can create a fully streamlined powder coating process that maximizes efficiency, quality, and profitability.

FAQ

Here are some common questions and answers related to electrostatic spray gun systems:

1. What are the primary benefits of using an electrostatic spray gun system?

The electrostatic spray gun system offers several key benefits, including high transfer efficiency, reduced waste, improved coating quality, and enhanced productivity. It is particularly effective in minimizing overspray, which not only saves materials but also reduces environmental impact by lowering VOC emissions.

2. How does the electrostatic spray gun system ensure safety during operation?

Safety is a critical aspect of operating an electrostatic spray gun system. Proper grounding of all equipment and personnel is essential to prevent static sparks that could lead to fires or electrical shocks. Operators should wear conductive shoes or use grounding straps to ensure any built-up charge can dissipate safely. Additionally, modern electrostatic spray gun systems often include safety features that adjust the electric charge if the gun gets too close to a grounded object.

3. Can waterborne paints be used with an electrostatic spray gun system?

Yes, waterborne paints can be used with an electrostatic spray gun system, but the selection of the gun and related equipment is crucial. Waterborne electrostatic systems often require specialized components to ensure proper charging and application of the paint. These systems are beneficial for reducing VOCs and improving environmental sustainability.

4. How does the electrostatic spray gun system improve coating adhesion?

While the electrostatic spray gun system enhances transfer efficiency, it does not directly improve coating adhesion. Adhesion is primarily dependent on the condition of the substrate and the properties of the coatings used. Proper surface preparation is key to achieving high-quality finishes.

5. What are the recommended operating conditions for an electrostatic spray gun system?

For optimal performance, the air flow speed in the spray booth should be lower than that used for traditional air-based spraying. This helps maintain the electrostatic effect and ensures efficient paint absorption. Grounding requirements are also critical; all equipment and personnel must be properly grounded to prevent static buildup.

6. How does the electrostatic spray gun system compare to traditional air spray guns in terms of efficiency and waste reduction?

The electrostatic spray gun system is significantly more efficient than traditional air spray guns. It achieves higher transfer efficiencies, reducing waste and material usage. This not only saves costs but also minimizes environmental impact by reducing VOC emissions and overspray.

In conclusion, the electrostatic spray gun system is a powerful tool for enhancing efficiency, quality, and sustainability in powder coating applications. By understanding its benefits, operation, and integration with other systems, manufacturers can optimize their production processes and achieve superior results.

In today's competitive manufacturing landscape, adopting cutting-edge technologies like the electrostatic spray gun system is crucial for staying ahead. With its unparalleled efficiency, environmental benefits, and versatility, this system is poised to revolutionize the powder coating industry. Whether you are a seasoned manufacturer or an emerging player, our electrostatic spray gun system offers the perfect blend of innovation and reliability to elevate your production capabilities.

Contact Us

To learn more about how our electrostatic spray gun system can transform your business, please do not hesitate to contact us. Our team of experts is ready to provide personalized solutions tailored to your specific needs. Together, let's harness the power of electrostatic technology to achieve unparalleled success in the world of powder coating.

Additional Considerations for Electrostatic Spray Gun Systems

When implementing an electrostatic spray gun system, it's essential to consider the entire production environment. This includes ensuring proper ventilation in the spray booth, maintaining optimal humidity levels, and using appropriate personal protective equipment to safeguard against potential hazards. By integrating these considerations with the advanced features of our electrostatic spray gun system, you can create a safe, efficient, and highly productive coating process.

Future Developments in Electrostatic Spray Gun Technology

As technology continues to evolve, we anticipate further advancements in electrostatic spray gun systems. These may include more sophisticated control systems, enhanced safety features, and expanded compatibility with a wider range of coating materials. Our commitment to innovation ensures that our clients remain at the forefront of powder coating technology, equipped with the latest tools to meet emerging challenges and opportunities.

In summary, the electrostatic spray gun system represents a significant leap forward in powder coating technology. Its ability to enhance efficiency, reduce waste, and improve coating quality makes it an indispensable asset for manufacturers across various industries. By embracing this technology and integrating it with complementary solutions, businesses can achieve superior results while contributing to a more sustainable future.