Content Menu

● Understanding Electrostatic Spray Guns

>> How Electrostatic Spray Guns Work

● Common Mistakes to Avoid

>> 1. Improper Grounding of the Workpiece

>> 2. Incorrect Application Distance

>> 3. Using the Wrong Spray Gun Settings

>> 4. Neglecting Equipment Cleaning and Maintenance

>> 5. Overlooking Environmental Conditions

>> 6. Ignoring Safety Precautions

● Tips for Effective Use of Electrostatic Spray Guns

>> 1. Choose the Right Materials

>> 2. Master Spray Techniques

>> 3. Monitor and Adjust Settings

>> 4. Use Appropriate Filters and Masks

● Troubleshooting Common Problems

>> Uneven Coating or Poor Film Thickness

>> Excessive Overspray

>> Clogging or Inconsistent Spray Patterns

>> Electrical Shocks or Sparks

● Frequently Asked Questions (FAQs)

Electrostatic spray guns have become an invaluable tool for industries requiring efficient, uniform coating applications. However, improper use can lead to inefficiencies, safety hazards, or poor finishing results. This comprehensive guide discusses the common mistakes to avoid when operating an electrostatic spray gun, ensuring optimal performance and a high-quality finish.

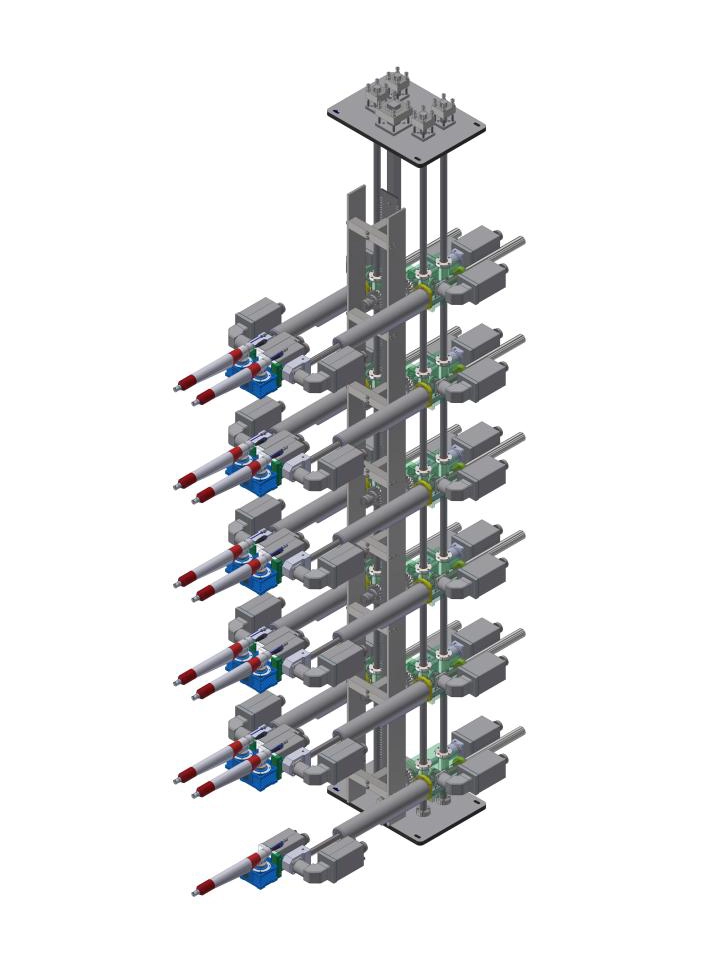

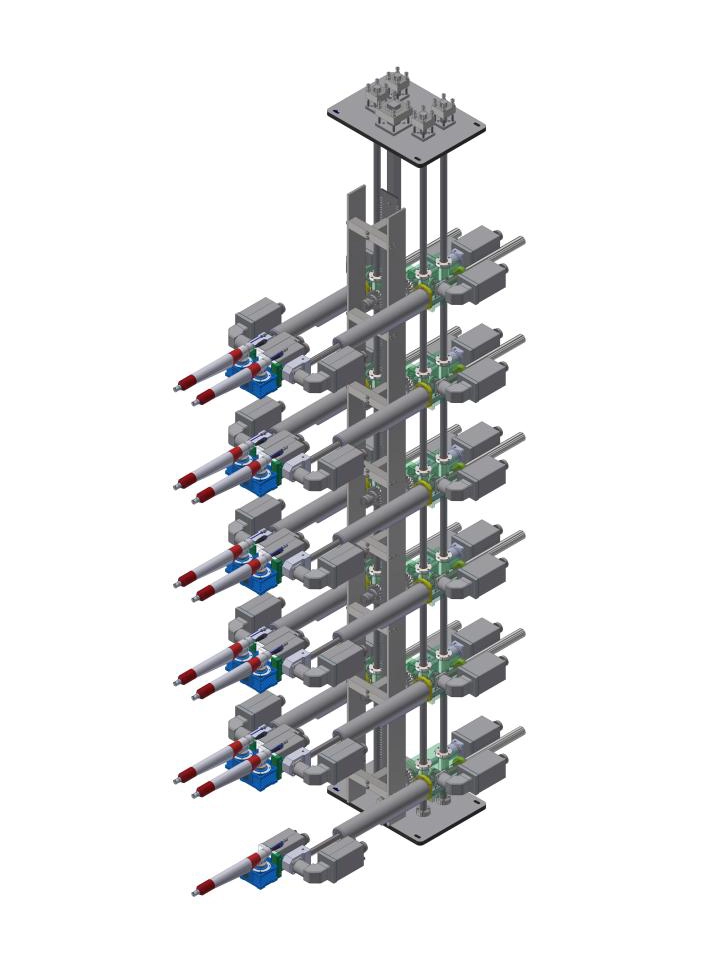

Understanding Electrostatic Spray Guns

Electrostatic spray guns use the principle of electrostatics to apply paint, powder, or other coatings. The material is electrically charged as it exits the nozzle, attracting it to the grounded target surface. This method enhances transfer efficiency, reduces overspray, and ensures even coverage.

How Electrostatic Spray Guns Work

The gun charges the particles either positively or negatively, creating an electrostatic field that directs the particles toward the opposite-charged surface. This increases the efficiency of coating material usage and leads to a smoother finish.

Common Mistakes to Avoid

Operating an electrostatic spray gun requires careful attention to several factors. The following sections highlight major errors that users often make and tips on preventing them.

1. Improper Grounding of the Workpiece

A critical mistake is failing to properly ground the object being sprayed. Since electrostatic spraying relies on the attraction between charged particles and a grounded surface, poor grounding dramatically reduces transfer efficiency.

- Always ensure the workpiece is securely grounded.

- Use grounding clamps or grounding wires recommended by the manufacturer.

- Regularly test grounding connections to avoid buildup of static charge.

2. Incorrect Application Distance

The distance between the spray gun and the target surface significantly affects coating quality. Spraying too close or too far can cause uneven coverage or excessive overspray.

- Maintain the recommended distance, usually between 6 to 10 inches.

- Adjust the distance depending on the type of coating material and part geometry.

- Practice consistent movement speed and maintain a perpendicular spray angle to the surface.

3. Using the Wrong Spray Gun Settings

Each coating or paint type requires specific pressure, voltage, and flow rate settings. Using incorrect settings can result in poor atomization, inconsistent charging, or excessive overspray.

- Refer to the spray gun and coating material manuals for optimal settings.

- Regularly calibrate the equipment to maintain accurate voltage and pressure levels.

- Adjust the settings in small increments to achieve the desired finish.

4. Neglecting Equipment Cleaning and Maintenance

Residue buildup inside the spray gun nozzle or charging components can impede performance and cause clogging.

- Clean the spray gun thoroughly after each use.

- Inspect and replace worn or damaged parts regularly.

- Follow manufacturer-recommended maintenance schedules.

5. Overlooking Environmental Conditions

Humidity, temperature, and airflow affect electrostatic spray performance. High humidity can reduce charge buildup, while excessive airflow can disperse charged particles unevenly.

- Avoid spraying in extremely humid or windy environments.

- Control airflow using screens or barriers if necessary.

- Maintain an optimal temperature range as specified by the equipment manual.

6. Ignoring Safety Precautions

Electrostatic spraying involves high voltages and flammable materials. Skipping safety protocols can result in electrical shock, fires, or exposure to harmful substances.

- Always wear protective gear, including gloves, goggles, and respirators.

- Ground all equipment correctly.

- Keep flammable materials away from the spray area.

- Follow local regulations for ventilation and hazardous material handling.

Tips for Effective Use of Electrostatic Spray Guns

Beyond avoiding mistakes, here are best practices to maximize the benefits of electrostatic spraying.

1. Choose the Right Materials

Ensure your coating materials are compatible with electrostatic spraying. Some paints and powders are specially formulated to optimize charge retention and film formation.

2. Master Spray Techniques

Practice steady, overlapping strokes to achieve uniform film thickness without runs or sags. Move the gun at a consistent speed to avoid uneven buildup.

3. Monitor and Adjust Settings

Regularly check spray patterns and thickness, adjust voltage and pressure as needed, and fine-tune the gun's parameters based on surface geometry and distance.

4. Use Appropriate Filters and Masks

Prevent contamination by using filters on compressed air and wearing masks to avoid inhaling overspray or powder particles.

Troubleshooting Common Problems

Even with care, problems can arise. Below are common issues and practical solutions.

Uneven Coating or Poor Film Thickness

- Check grounding connections and spray technique.

- Confirm correct gun distance and spray angle.

- Adjust voltage and pressure settings.

Excessive Overspray

- Reduce applied voltage or lower pressure.

- Maintain recommended spraying distance.

- Use spray screens or barriers around the work area.

Clogging or Inconsistent Spray Patterns

- Clean gun components regularly.

- Replace worn nozzles or damaged parts.

- Use the appropriate coating viscosity for the gun.

Electrical Shocks or Sparks

- Confirm all grounding is secure.

- Avoid spraying in damp conditions.

- Ensure all equipment is inspected and maintained for electrical safety.

Frequently Asked Questions (FAQs)

Q1: Why is grounding so essential in electrostatic spraying?

Grounding completes the electrical circuit, allowing charged particles to be attracted to the target. Without grounding, particles disperse into the air, reducing transfer efficiency and increasing waste.

Q2: How often should I clean my electrostatic spray gun?

It is best to clean the gun thoroughly after each use to prevent buildup and maintain consistent performance.

Q3: Can electrostatic spray guns be used outdoors?

While possible, outdoor use requires controlling environmental factors, especially wind and humidity, to avoid poor finish quality.

Q4: What safety precautions are necessary during electrostatic spraying?

Wear appropriate protective equipment, ensure grounding of all components, work in well-ventilated areas, and keep flammable materials away.

Q5: How do I know if my spray gun settings are correct?

Consult the equipment manual and coating material guidelines, and perform test sprays to optimize voltage, pressure, and distance for the best finish.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.