Content Menu

● The Rise of Automation in Powder Coating

>> Enhanced Precision with Robotics

>> Integration of Industry 4.0 Technologies

● Sustainability and Eco-Friendly Practices

>> Adoption of Sustainable Materials

>> Energy Efficiency in Production

● Customization and Flexibility

>> Demand for Personalized Coatings

>> Quick Changeover Capabilities

● Quality Control and Consistency

>> Real-Time Monitoring Systems

>> Predictive Maintenance

● The Future of Powder Coating Automation

>> Fully Automated Production Lines

>> Integration of Smart Technologies

● Conclusion

>> Frequently Asked Questions

The powder coating industry is undergoing a significant transformation driven by automation and advanced technologies. As manufacturers strive for greater efficiency, quality, and sustainability, understanding the key trends in automation is essential for staying competitive. This article explores the latest automation trends in the powder coating industry, highlighting the technologies and practices that are shaping its future.

The Rise of Automation in Powder Coating

Enhanced Precision with Robotics

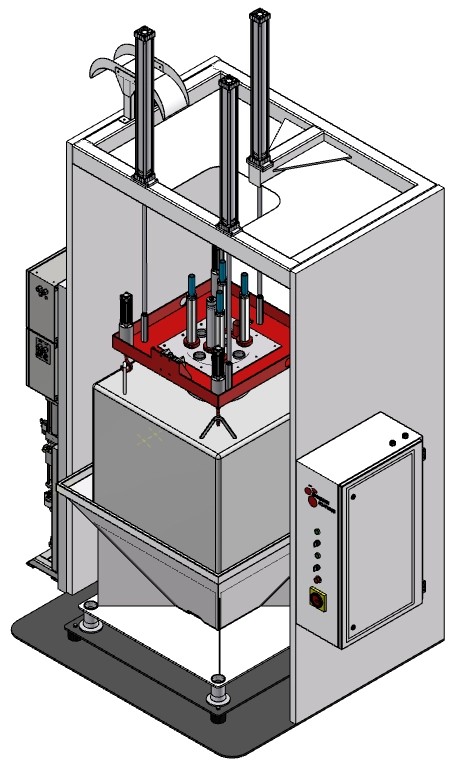

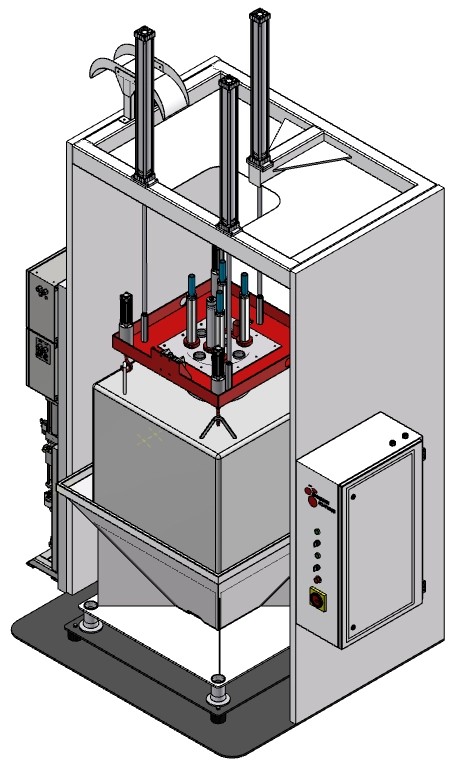

One of the most notable trends in the powder coating industry is the increasing use of robotics. Automated systems equipped with robotic arms are now commonplace in powder coating facilities. These robots ensure precise application of coatings, significantly reducing human error and enhancing the overall quality of the finish. The ability to program these robots for specific tasks allows for greater flexibility in production, enabling manufacturers to switch between different products with minimal downtime.

Integration of Industry 4.0 Technologies

The advent of Industry 4.0 has brought about a new era of connectivity and data-driven decision-making in manufacturing. In the powder coating sector, this means integrating Internet of Things (IoT) devices and artificial intelligence (AI) into production processes. IoT sensors can monitor various parameters such as temperature, humidity, and powder flow in real-time, allowing for immediate adjustments to maintain optimal conditions. AI algorithms analyze this data to predict maintenance needs and optimize production schedules, leading to increased efficiency and reduced waste.

Sustainability and Eco-Friendly Practices

Adoption of Sustainable Materials

As environmental concerns continue to rise, the powder coating industry is responding by adopting more sustainable practices. This includes the use of eco-friendly powders that are free from volatile organic compounds (VOCs). These materials not only reduce environmental impact but also improve workplace safety for employees. Manufacturers are increasingly seeking certifications for their products to demonstrate their commitment to sustainability, which can enhance their marketability.

Energy Efficiency in Production

Automation also plays a crucial role in improving energy efficiency within powder coating operations. Automated systems can optimize energy use by adjusting the curing process based on real-time data. For instance, smart ovens can modify their energy consumption based on the load and type of coating being applied, leading to significant cost savings and a reduced carbon footprint.

Customization and Flexibility

Demand for Personalized Coatings

The market is witnessing a growing demand for customized powder coating solutions. Automation allows manufacturers to quickly adapt to these changing customer preferences. Automated systems can be programmed to handle various colors and finishes, enabling rapid changes without the need for extensive manual intervention. This flexibility not only meets customer demands but also enhances production efficiency.

Quick Changeover Capabilities

Modern automated powder coating systems are designed for quick changeovers between different products. This capability is essential for manufacturers looking to reduce lead times and increase throughput. Automated color change systems can switch between different powder colors with minimal waste, allowing for more efficient production runs.

Quality Control and Consistency

Real-Time Monitoring Systems

Quality control is paramount in the powder coating industry, and automation is enhancing this aspect significantly. Real-time monitoring systems equipped with advanced sensors can detect inconsistencies in the coating process as they occur. This allows for immediate corrective actions, ensuring that the final product meets the required specifications. Automated quality checks reduce the likelihood of defects and rework, ultimately saving time and resources.

Predictive Maintenance

Another critical aspect of automation in powder coating is predictive maintenance. By utilizing IoT devices and AI, manufacturers can monitor the health of their equipment continuously. Predictive maintenance systems analyze data from machinery to forecast potential failures before they occur. This proactive approach minimizes downtime and extends the lifespan of equipment, leading to more efficient operations.

The Future of Powder Coating Automation

Fully Automated Production Lines

The future of powder coating is leaning towards fully automated production lines. These systems will operate with minimal human intervention, relying on advanced robotics and AI to manage the entire coating process. This shift not only enhances efficiency but also allows for greater scalability in production, enabling manufacturers to meet increasing demand without compromising quality.

Integration of Smart Technologies

As technology continues to evolve, the integration of smart technologies in powder coating processes will become more prevalent. This includes the use of machine learning algorithms that can adapt processes based on historical data and real-time feedback. Such advancements will lead to even higher levels of efficiency and quality, positioning manufacturers at the forefront of the industry.

Conclusion

The powder coating industry is on the brink of a technological revolution, driven by automation and smart technologies. As manufacturers embrace these trends, they will not only improve their operational efficiency but also enhance product quality and sustainability. Staying ahead in this rapidly evolving landscape requires a commitment to innovation and a willingness to adapt to new technologies.

Frequently Asked Questions

1. What are the main benefits of automation in powder coating?

Automation enhances precision, reduces human error, improves efficiency, and allows for real-time monitoring of the coating process.

2. How does Industry 4.0 impact powder coating?

Industry 4.0 introduces IoT and AI technologies that enable data-driven decision-making, predictive maintenance, and improved production efficiency.

3. What sustainable practices are being adopted in powder coating?

Manufacturers are using eco-friendly powders, optimizing energy consumption, and implementing waste reduction strategies to minimize environmental impact.

4. How does automation improve quality control in powder coating?

Automated systems provide real-time monitoring and immediate corrective actions, ensuring consistent quality and reducing defects.

5. What is the future of automation in the powder coating industry?

The future includes fully automated production lines and the integration of smart technologies that enhance efficiency and adaptability in manufacturing processes.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.