Content Menu

● Understanding the Basics of Spray Gun Units

>> What is a Spray Gun Unit?

>> Types of Spray Guns

● Key Technical Factors That Define a High-Quality Spray Gun Unit

>> 1. Atomization Efficiency

>> 2. Adjustable Spray Patterns

>> 3. Material Compatibility and Fluid Delivery

>> 4. Ergonomics and Handling

>> 5. Durability and Maintenance

● Advanced Features in Premium Spray Gun Units

>> HVLP Technology and Transfer Efficiency

>> Electrostatic Charging for Superior Adhesion

>> Advanced Air Filtration Systems

● Choosing the Right Spray Gun Unit for Your Application

>> Industrial vs. Hobby Use

>> Surface and Material Considerations

>> Budget and Maintenance

● Best Practices for Maintaining Spray Gun Units

>> Daily Cleaning Procedures

>> Periodic Inspections

>> Proper Storage

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is the main difference between HVLP and conventional spray guns?

>> 2. How important is nozzle size in a spray gun?

>> 3. Can I use the same spray gun for different types of paint?

>> 4. Why is atomization efficiency important in a spray gun?

>> 5. How often should spray guns be cleaned?

Spray guns are essential tools in many industries, from automotive painting to woodworking, manufacturing, and even medical applications. The quality of a spray gun unit directly impacts the efficiency, finish, and overall results of the application process. But what truly defines a high-quality spray gun unit? This article dives deep into the technical aspects and key features that make a spray gun unit stand out, helping professionals and hobbyists alike make informed decisions.

Understanding the Basics of Spray Gun Units

What is a Spray Gun Unit?

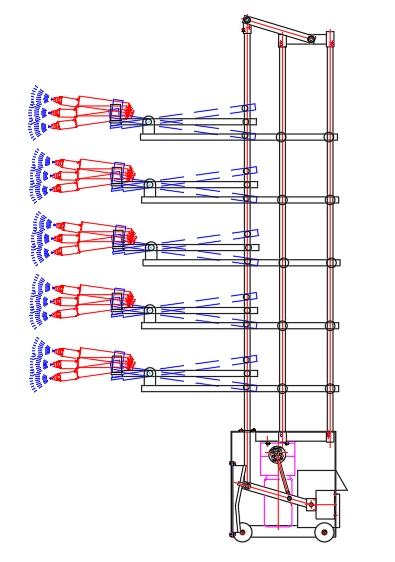

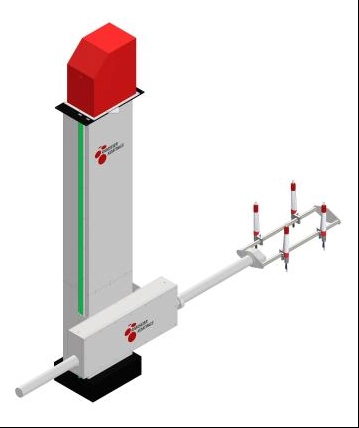

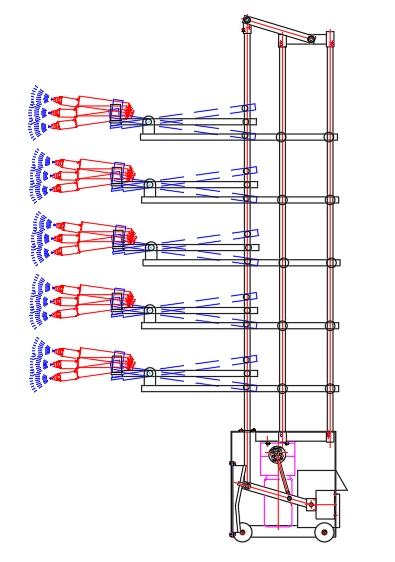

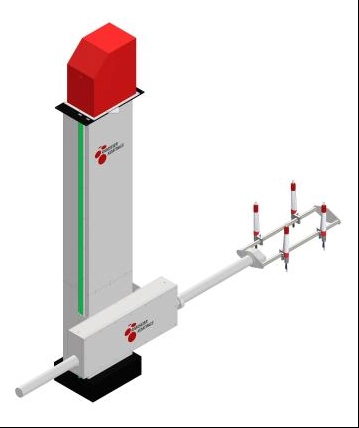

A spray gun is a device used to apply paint, coatings, or other liquids in fine droplets to a surface. It works by atomizing the liquid into a spray pattern using compressed air or other propellants. A spray gun unit typically consists of the gun itself, a paint container (cup or hopper), an air compressor or source, and sometimes a regulator or filter system.

Types of Spray Guns

- Conventional Spray Guns: Use high air pressure to atomize paint.

- High Volume Low Pressure (HVLP) Guns: Deliver a high volume of paint at lower pressure, reducing overspray and wastage.

- Airless Spray Guns: Use high fluid pressure instead of air to atomize the paint, often used for thicker coatings.

- Electrostatic Spray Guns: Use an electrical charge to attract paint particles to the target surface, improving transfer efficiency.

Each type has its advantages and is chosen based on application needs, material viscosity, and desired finish quality.

Key Technical Factors That Define a High-Quality Spray Gun Unit

1. Atomization Efficiency

Atomization is the core function of a spray gun. A high-quality unit produces a fine, uniform mist of paint particles, ensuring smooth and even application.

- Nozzle and Tip Design: Precision-machined nozzles with consistent orifice sizes promote uniform paint flow and fine atomization. Materials like stainless steel or carbide enhance durability.

- Air Cap Engineering: Good air caps help shape the spray pattern and improve paint breakup, reducing large droplets and runs.

- Pressure Regulation: Stable, adjustable air pressure ensures consistent atomization without spitting or uneven spray.

2. Adjustable Spray Patterns

Different tasks require different spray widths and shapes. A versatile spray gun unit offers adjustable spray patterns such as:

- Round Spray: Best for detail work and edges.

- Fan Spray: Ideal for broad, even coverage.

- Oval or Horizontal/Vertical Spray: Useful for corners or irregular surfaces.

A controllable pattern adjustment knob or air cap rotation adds to operational flexibility.

3. Material Compatibility and Fluid Delivery

High-quality spray guns can handle a broad range of materials including lacquers, enamels, urethanes, primers, and stains. This versatility depends on:

- Fluid Tip Size: Various tip sizes accommodate different fluid viscosities.

- Cup/Hopper Design: Gravity-feed, siphon-feed, or pressure-feed systems each suit different materials and volume requirements.

- Sealing and Build Materials: Resistant seals and corrosion-resistant materials avoid degradation when using harsh chemicals or water-based paints.

4. Ergonomics and Handling

Spray painting can be physically demanding. A high-grade spray gun unit emphasizes:

- Weight: Lightweight yet sturdy materials reduce operator fatigue.

- Grip Design: Rounded, textured grips improve comfort and control.

- Trigger Sensitivity: Smooth, responsive triggers allow precise output control to avoid overspray.

5. Durability and Maintenance

Long-lasting performance reduces downtime and replacement costs:

- Material Quality: Industrial-grade metals and composites resist wear, corrosion, and impact.

- Ease of Cleaning: Quick disassembly and accessible parts simplify cleaning to prevent clogging.

- Serviceability: Availability of spare parts and straightforward repairs ensure minimal disruption.

Advanced Features in Premium Spray Gun Units

HVLP Technology and Transfer Efficiency

High Volume Low Pressure spray guns have revolutionized coating application by using lower air pressure to reduce overspray and material waste. This technology improves:

- Transfer Efficiency: A higher percentage of spray material lands on the target surface.

- Environmental Impact: Less paint mist in the air means safer workplaces and less environmental contamination.

Electrostatic Charging for Superior Adhesion

Electrostatic spray guns impart a charge to paint particles, attracting them to grounded surfaces, thereby improving:

- Coating Uniformity: Even coverage, even on complex shapes.

- Material Savings: Less paint needed for complete coverage.

- Finish Quality: Reduced runs, drips, and better curing.

Advanced Air Filtration Systems

Removing moisture, oil, and particles from compressed air prolongs spray gun life and improves finish quality. High-end units incorporate:

- Built-in Filters

- Air Regulators

- Moisture Traps

Ensuring clean, dry air is especially vital for fine finishing work.

Choosing the Right Spray Gun Unit for Your Application

Industrial vs. Hobby Use

Professional environments demand higher throughput, reliability, and precision, thus expensive and robust spray guns are justified. Hobbyists may prioritize ease of use and cost-effectiveness.

Surface and Material Considerations

Porous surfaces, metals, plastics, and wood all require different approaches:

- Heavier paints usually require larger fluid tips or airless guns.

- Fine finishes (like automotive paint) demand meticulous atomization and spray control.

Budget and Maintenance

While it might be tempting to buy cheaper, low-quality spray guns, they often require replacement more frequently and provide inconsistent results. Investing in quality reduces overall lifetime cost and enhances output quality.

Best Practices for Maintaining Spray Gun Units

Daily Cleaning Procedures

- Flush the gun immediately after use with appropriate solvents.

- Disassemble and clean nozzles and air caps regularly to prevent clogging.

Periodic Inspections

- Check for wear and tear on seals and tips.

- Inspect for corrosion, especially if water-based paints are used.

Proper Storage

- Store in a clean, dry environment.

- Use protective caps on nozzles to avoid damage.

Conclusion

A high-quality spray gun unit is defined by precise atomization, adjustable spray patterns, material compatibility, ergonomic design, and robust construction. Advanced technologies such as HVLP and electrostatic charging elevate performance further. Choosing the right spray gun depends on the specific application, material requirements, and budget considerations. Proper maintenance ensures longevity and consistent results. By focusing on these key technical insights, users can achieve superior finishes and maximize their productivity in spraying applications.

Frequently Asked Questions (FAQs)

1. What is the main difference between HVLP and conventional spray guns?

HVLP spray guns use lower air pressure with higher volume to deliver paint, resulting in less overspray and better material efficiency, while conventional guns use high air pressure which can waste more paint.

2. How important is nozzle size in a spray gun?

Nozzle size affects the thickness and volume of paint delivered. Choosing the correct size is crucial for different paint types and desired finishes.

3. Can I use the same spray gun for different types of paint?

High-quality spray guns are often versatile enough to handle various paint materials, but always check manufacturer recommendations for compatibility, especially with thicker or specialty coatings.

4. Why is atomization efficiency important in a spray gun?

Efficient atomization produces fine paint droplets ensuring an even surface finish and helps in reducing paint wastage, overspray, and defects such as runs or orange peel.

5. How often should spray guns be cleaned?

Spray guns should be cleaned after every use to prevent clogs and maintain performance. Regular deep cleaning and maintenance help extend the lifespan of the unit.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.