Content Menu

● Introduction

● What Are Personalized Automatic Spray Booth Systems?

● Advantages of Personalized Automatic Spray Booth Systems

>> Enhanced Performance Through Customization

>> Streamlined Workflow and Increased Productivity

>> Environmental and Safety Compliance

● Core Components of Personalized Automatic Spray Booth Systems

>> Automatic Spray Guns

>> Custom Booth Design

>> Control and Automation Systems

● Industries Benefiting from Personalized Automatic Spray Booth Systems

>> Automotive and Aerospace

>> Industrial and Heavy Equipment

>> Electronics and Consumer Goods

● Designing Your Personalized Automatic Spray Booth System

>> Needs Assessment and Consultation

>> Engineering and Customization

>> Installation and Support

● Case Studies Highlighting the Impact of Personalized Systems

● Frequently Asked Questions (FAQs)

● Conclusion

Introduction

In today's competitive manufacturing and finishing industries, achieving superior coating quality while maximizing efficiency is paramount. Personalized Automatic Spray Booth Systems have emerged as a game-changing solution, offering bespoke designs that cater specifically to the unique requirements of various industries. This article explores the advantages, design considerations, and applications of these customized systems, highlighting how they optimize workflow, enhance coating quality, and meet stringent environmental and safety standards.

What Are Personalized Automatic Spray Booth Systems?

Personalized Automatic Spray Booth Systems refer to spray booth setups that are custom-engineered to fit the exact needs of a business or production process. Unlike standard, off-the-shelf booths, these systems integrate automatic spraying technologies with tailored booth dimensions, airflow management, filtration, and control features to deliver optimal finishing results.

These systems are particularly crucial in industries requiring precise and consistent coatings, such as automotive refinishing, aerospace manufacturing, heavy equipment production, and industrial painting[2][4][5].

Advantages of Personalized Automatic Spray Booth Systems

Enhanced Performance Through Customization

A key benefit of personalized automatic spray booth systems is their precision tailoring to specific operational requirements. Custom designs consider factors such as the size and shape of items being coated, types of coatings used, and environmental conditions. This ensures optimal airflow patterns, exhaust configurations, and filtration systems are implemented to maximize coating efficiency and quality[2][4].

Streamlined Workflow and Increased Productivity

By integrating automatic spray guns and robotics within a personalized booth, manufacturers achieve a more streamlined workflow. The booth layout can be optimized to reduce operator movement and downtime, while automated systems accelerate the coating process and improve consistency. Features like advanced drying technologies and specialized lighting further enhance productivity and accuracy[2][4].

Environmental and Safety Compliance

Personalized booths are designed to comply with local and international safety and environmental regulations. Proper ventilation and filtration reduce volatile organic compound (VOC) emissions and hazardous air pollutants (HAPs), protecting worker health and minimizing environmental impact[6][5].

Core Components of Personalized Automatic Spray Booth Systems

Automatic Spray Guns

Automatic spray guns, including electrostatic types, are integral to these systems. They offer high transfer efficiency, uniform coating, and reduced overspray, leading to cost savings and improved finish quality. Electrostatic spray guns charge paint particles, improving adhesion and reducing waste[6][9].

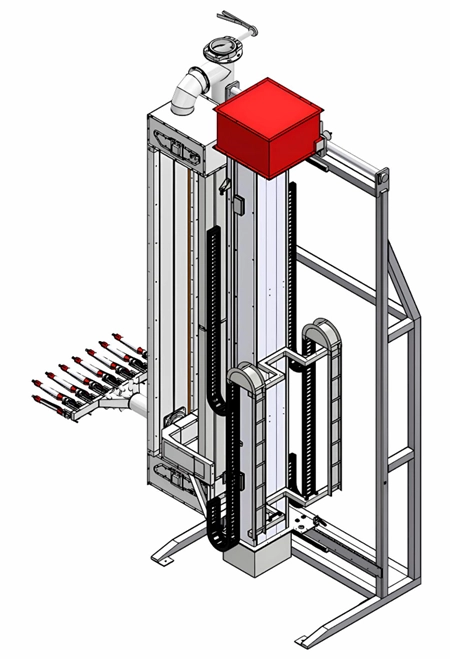

Custom Booth Design

The booth itself is engineered to fit the production environment and product specifications. This includes tailored dimensions, airflow management to control overspray and fumes, and filtration systems to maintain air quality. Custom booths can accommodate large or uniquely shaped items and integrate with robotic sprayers or automated conveyors[2][4][5].

Control and Automation Systems

Personalized systems incorporate advanced controls for regulating spray parameters, booth ventilation, and curing processes. Automation enhances repeatability and reduces operator error, ensuring consistent high-quality finishes[4].

Industries Benefiting from Personalized Automatic Spray Booth Systems

Automotive and Aerospace

High precision and efficiency are critical in automotive and aerospace coatings. Personalized booths ensure flawless finishes on complex parts and large vehicles, while meeting strict environmental standards[2][4].

Industrial and Heavy Equipment

Large equipment and industrial components require booths that can handle oversized items and specialized coatings. Custom systems optimize airflow and spray parameters to ensure durable, uniform coatings[2][4].

Electronics and Consumer Goods

Smaller-scale applications benefit from booths designed for high throughput and fine detail, using automated spray guns for consistent results[4][6].

Designing Your Personalized Automatic Spray Booth System

Needs Assessment and Consultation

The design process begins with a thorough assessment of your production needs, coating materials, and environmental requirements. Expert consultation ensures the booth system aligns with your operational goals[5].

Engineering and Customization

Based on the assessment, engineers develop a tailored solution addressing booth size, airflow dynamics, filtration, spray technology, and automation integration. This phase includes compliance checks with safety and environmental regulations[4][5].

Installation and Support

Professional installation ensures the system functions as designed. Ongoing support and maintenance services help sustain performance and adapt to evolving production needs[5].

Case Studies Highlighting the Impact of Personalized Systems

- Dixie Technical College: Customized booths designed to meet unique educational and operational requirements, demonstrating adaptability[4].

- Precision Body & Paint: A system engineered for cold climates, ensuring efficient operation year-round[4].

- Fender Music Instruments: Integration of robotic spray systems within a custom booth to achieve consistent high-quality finishes[4].

Frequently Asked Questions (FAQs)

1. What makes a spray booth system "personalized"?

A personalized spray booth system is custom-designed to meet the specific size, coating, and workflow requirements of a business, rather than using a standard, one-size-fits-all booth[2][4].

2. How do automatic spray guns improve coating efficiency?

Automatic spray guns, especially electrostatic types, provide higher transfer efficiency and uniform coverage, reducing paint waste and improving finish quality[6][9].

3. Can personalized spray booths handle different types of coatings?

Yes, these booths can be engineered to accommodate various coatings, including standard, specialty, and water-based paints, with appropriate ventilation and filtration systems[2][6].

4. What industries benefit most from personalized automatic spray booth systems?

Automotive, aerospace, industrial equipment, electronics, and consumer goods manufacturing are key industries that benefit from these tailored systems[2][4].

5. How do personalized booths ensure environmental compliance?

They incorporate advanced ventilation and filtration technologies designed to reduce VOC and HAP emissions, meeting local and international environmental regulations[5][6].

Conclusion

Personalized Automatic Spray Booth Systems represent the future of industrial coating technology. By offering tailored solutions that integrate automatic spraying with custom booth designs, these systems maximize efficiency, improve coating quality, and ensure compliance with environmental and safety standards. For manufacturers seeking to enhance their finishing processes, investing in a personalized system is a strategic move toward operational excellence.

[1] https://www.spraysystems.com

[2] https://gsbindustries.com/products/custom-paint-booths/

[3] https://relyonusa.com/custom-paint-booths-ventilation-systems/

[4] https://www.spraysystems.com/custom-solutions/

[5] https://relyonusa.com/services/custom-spray-booths/

[6] https://www.graco.com/cn/zh/in-plant-manufacturing/products/liquid-coating/spray-booth/spray-guns-applicators/electrostatic-paint-spray-guns.html

[7] https://www.paint-booths.com/custom-paint-booths.html

[8] https://patents.google.com/patent/CN107497620A/zh

[9] https://patents.google.com/patent/CN101014415A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.