Content Menu

● Understanding Spray Gun Units

>> What Is a Spray Gun Unit?

>> Components of a Spray Gun Unit

● How Spray Gun Units Enhance Coating Uniformity

>> Atomization Quality

>>> Factors Influencing Atomization

>> Controlled Spray Patterns

● Improving Coverage with Spray Gun Units

>> Consistent Material Flow

>> Pressure Regulation

>> Efficient Transfer Efficiency

● Types of Spray Gun Units and Their Impact on Coating Quality

>> Conventional Spray Guns

>> High Volume Low Pressure (HVLP) Guns

>> Electrostatic Spray Guns

>> Airless Spray Guns

● Operational Techniques to Maximize Uniformity and Coverage

>> Maintaining Correct Distance and Angle

>> Overlapping Each Pass

>> Adjusting Speed and Movement

>> Multiple Thin Coats vs. One Thick Coat

● Maintenance and Calibration for Consistent Performance

>> Cleaning the Spray Gun Thoroughly

>> Checking and Replacing Nozzles

>> Calibrating Pressure and Flow

>> Inspecting and Maintaining Air Compressors

● Benefits of Using Advanced Spray Gun Units for Coating Applications

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What factors affect the uniformity of a spray coating?

>> 2. How does an HVLP spray gun improve coverage compared to conventional guns?

>> 3. Why is maintenance important for spray gun units?

>> 4. What role does spray pattern adjustment play in coating quality?

>> 5. Can electrostatic spray guns be used for all types of coatings?

Achieving a high-quality finish in painting and coating applications is pivotal for durability, aesthetics, and protection of surfaces across various industries. One of the most critical tools in this process is the spray gun unit. Spray gun units enhance coating uniformity and coverage, ensuring that the applied material forms a consistent, even layer that adheres well and lasts long. This comprehensive article explores how spray gun units improve coating uniformity and coverage, delving into their types, components, operational techniques, and maintenance.

Understanding Spray Gun Units

What Is a Spray Gun Unit?

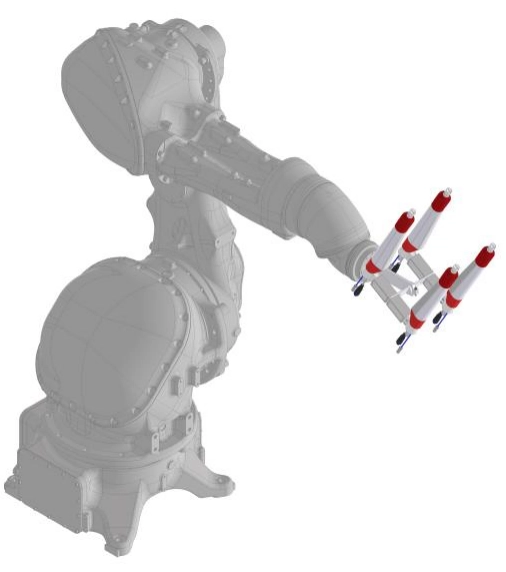

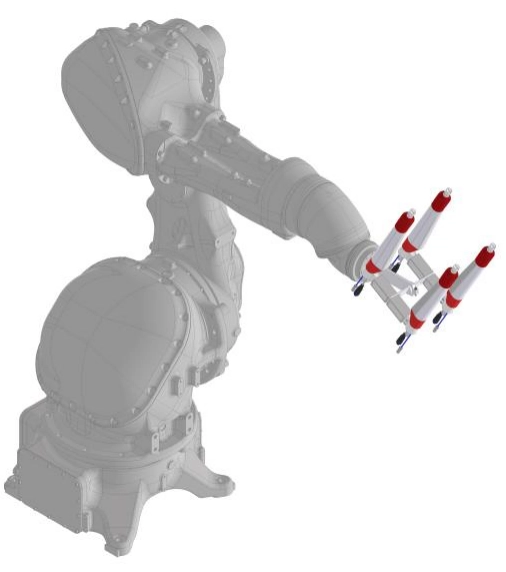

A spray gun unit is a device that atomizes coating materials, such as paint, lacquer, or varnish, into fine droplets and propels them onto a surface. The unit typically includes a spray gun, an air compressor or pressure source, and accessory components like hoses and regulators. Spray gun units are crucial in industries ranging from automotive and aerospace to furniture manufacturing and construction.

Components of a Spray Gun Unit

- Spray Gun: The main tool that mixes air and coating material to create a spray pattern.

- Air Compressor: Supplies compressed air to atomize the coating material and deliver it consistently.

- Hoses and Regulators: Control the flow and pressure of air and materials to optimize spray performance.

- Material Cup or Container: Holds the coating material to be sprayed.

How Spray Gun Units Enhance Coating Uniformity

Achieving uniformity in coating involves covering the surface evenly without streaks, drips, or thin spots. Spray gun units contribute to this goal in several ways.

Atomization Quality

Atomization refers to breaking down the coating material into tiny droplets. Spray guns with high-quality atomization create fine, consistent droplets that distribute evenly on the target surface. This reduces the risk of uneven buildup or splotches and promotes smooth finishes.

Factors Influencing Atomization

- Air Pressure: Correct air pressure breaks the liquid into smaller particles.

- Nozzle Size: Appropriately sized nozzles produce a consistent droplet size.

- Viscosity of Coating Material: Spray guns can adjust for different viscosities to maintain fine atomization.

Controlled Spray Patterns

Spray guns offer adjustable spray patterns—such as fan, circular, or elliptical shapes—that match the requirements of the surface and product type. This control helps achieve uniform coverage by customizing the spray width and overlap.

Improving Coverage with Spray Gun Units

Coating coverage refers to how well the sprayed material envelops the surface, including hard-to-reach areas, corners, and edges.

Consistent Material Flow

Spray gun units allow precise regulation of the material flow rate, ensuring an adequate amount of coating is applied without waste or overapplication. This consistency prevents patchiness and reduces the need for excessive layers.

Pressure Regulation

Maintaining a stable and optimal pressure throughout the spraying process results in smooth and continuous material delivery. Pressure regulators and feedback systems help avoid fluctuations that could cause uneven coating thickness.

Efficient Transfer Efficiency

Transfer efficiency is the percentage of coating material that adheres to the substrate compared to what is sprayed. Spray gun technologies aim to maximize this through better atomization and spray control, minimizing overspray and wastage.

Types of Spray Gun Units and Their Impact on Coating Quality

Various spray gun units exist, each designed for specific needs and coating types. Understanding their differences is essential to selecting the right tool for achieving optimal uniformity and coverage.

Conventional Spray Guns

Conventional spray guns use high air pressure to atomize and propel paint. They tend to create more overspray and lower transfer efficiency, but are still preferred for certain jobs requiring heavy-duty application.

High Volume Low Pressure (HVLP) Guns

HVLP guns atomize paint at low pressure while using a high volume of air. They provide better transfer efficiency and less overspray, resulting in more uniform coatings and controlled coverage, especially for detailed finishes.

Electrostatic Spray Guns

Electrostatic guns impart an electric charge to the coating particles, causing them to be attracted to the grounded workpiece. This effect improves transfer efficiency dramatically and promotes uniform coverage, even in complex geometries.

Airless Spray Guns

Airless spray guns use high fluid pressure without compressed air for atomization. They deliver thicker coats with fewer passes, reducing application time, and often produce very uniform coverage on large surfaces.

Operational Techniques to Maximize Uniformity and Coverage

Proper use of spray gun units is critical to optimizing coating results. Some key operating techniques include:

Maintaining Correct Distance and Angle

Holding the spray gun at the correct distance (usually 6 to 12 inches) and a perpendicular angle to the surface promotes even material deposition without excess buildup.

Overlapping Each Pass

Consistent overlapping of spray passes by approximately 50% ensures that no gaps are left between passes, improving uniformity.

Adjusting Speed and Movement

Smooth and steady movement at a controlled speed prevents runs or sags by distributing the coating evenly.

Multiple Thin Coats vs. One Thick Coat

Applying several thin layers instead of one thick layer reduces drip formation, improves drying times, and results in a more uniform finish.

Maintenance and Calibration for Consistent Performance

Regular maintenance of spray gun units enhances their ability to provide uniform and consistent coverage.

Cleaning the Spray Gun Thoroughly

Coating residue can clog nozzles, disrupt flow, and affect spray patterns. Thorough cleaning after every use is critical to maintain atomization quality.

Checking and Replacing Nozzles

Nozzle wear changes the spray pattern and droplet size. Inspecting and replacing worn nozzles ensures consistent spray characteristics.

Calibrating Pressure and Flow

Periodically calibrating the air pressure, flow rate, and spray pattern settings keeps the equipment performing at peak efficiency.

Inspecting and Maintaining Air Compressors

Clean, dry, and regulated air supply contributes to stable spraying conditions, reducing defects caused by inconsistent atomization.

Benefits of Using Advanced Spray Gun Units for Coating Applications

Spray gun units engineered with modern technology offer numerous advantages:

- Improved Finish Quality: Enhanced atomization and control eliminate surface defects.

- Material Savings: Higher transfer efficiency minimizes overspray and waste.

- Faster Application: Better coverage reduces the number of coats and application time.

- Health and Environmental Impact: Modern units reduce volatile organic compound (VOC) emissions by optimizing material usage.

- Versatility: Adjustable settings tailor the spray to a wide range of materials and surfaces.

Conclusion

Spray gun units play a vital role in improving coating uniformity and coverage by delivering finely atomized material in controlled spray patterns and consistent flow rates. The choice of spray gun type, proper operational techniques, and rigorous maintenance are equally important in achieving high-quality, durable finishes. As technology advances, spray gun units continue to evolve, providing better control, efficiency, and environmental benefits for various coating applications.

Frequently Asked Questions (FAQ)

1. What factors affect the uniformity of a spray coating?

Uniformity depends on atomization quality, air pressure, nozzle size, spray pattern, distance, angle, and operator technique.

2. How does an HVLP spray gun improve coverage compared to conventional guns?

HVLP guns use lower pressure and higher air volume, reducing overspray and increasing transfer efficiency, leading to more uniform coverage and less wasted material.

3. Why is maintenance important for spray gun units?

Maintenance prevents clogging, nozzle wear, and inconsistent air or material flow, all of which can negatively impact coating uniformity and coverage.

4. What role does spray pattern adjustment play in coating quality?

Adjusting the spray pattern aligns the sprayed material to the surface shape and size, ensuring even application and minimizing gaps or heavy spots.

5. Can electrostatic spray guns be used for all types of coatings?

Electrostatic spray guns are effective for many coatings but work best with conductive materials and grounded substrates; some coatings or surfaces may require different methods.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.