Content Menu

● How Automatic Electrostatic Spray Guns Work

● Key Features to Consider When Buying

>> Transfer Efficiency and Coating Performance

>> Compatibility with Coating Materials

>> Physical Build and Durability

>> Automation Compatibility and Installation

>> Safety Features

>> Maintenance and Cleaning

>> Routine Maintenance Steps

● Additional Considerations

>> Power Source and Mobility

>> Cost and Warranty

● Frequently Asked Questions (FAQs)

An automatic electrostatic spray gun is a highly efficient tool that leverages electrostatic charge to apply coatings such as paint, powder, pesticides, and other liquids uniformly and with minimal waste. This technology is widely used in industrial and agricultural applications to optimize coverage, reduce overspray, and save material. Choosing the right automatic electrostatic spray gun can significantly affect the quality of the finish and the operational costs. This guide covers the key features to consider when buying an automatic electrostatic spray gun, explains how the technology works, and explores practical aspects of selection, maintenance, and usage.

How Automatic Electrostatic Spray Guns Work

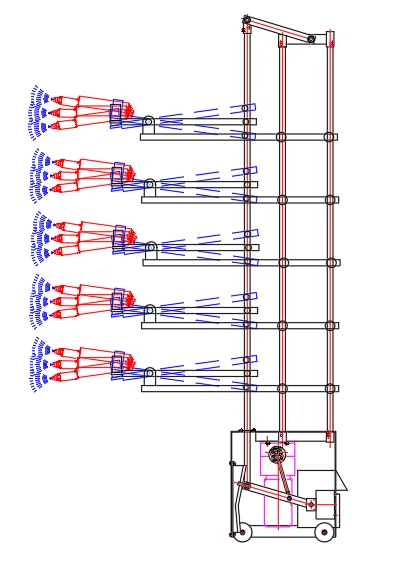

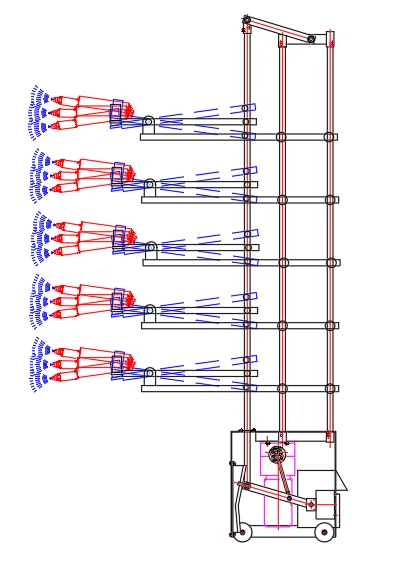

Automatic electrostatic spray guns operate by electrically charging paint or coating particles as they pass through the nozzle. These charged particles are then attracted to the grounded surface being coated, which enhances the efficiency of the coverage and reduces overspray. The electrostatic charge allows particles to wrap around complex shapes for uniform coverage even in hard-to-reach areas.

The automatic feature refers to the motorized or robotic system that continuously feeds paint or coating to the spray gun, allowing faster and more consistent application compared to manual spray guns. This integration with automated painting systems or robots is common in manufacturing lines.

Key advantages of automatic electrostatic spray guns include:

- Transfer efficiency up to 90%, meaning less wasted material

- Superior finish quality with smooth, even coats

- Reduced volatile organic compound (VOC) emissions due to less overspray

- Time savings through continuous feed and automation integration

- Environmental benefits via material conservation

Key Features to Consider When Buying

Transfer Efficiency and Coating Performance

Transfer efficiency measures how much of the sprayed material actually adheres to the target surface versus what is lost to overspray or bounce-back. Higher transfer efficiency means less wasted paint, cost savings, and less environmental impact.

- Look for spray guns with transfer efficiencies of 80-90% or higher.

- Electrostatic charging is the main driver of high transfer efficiency.

- Adjustable voltage ranges (typically 40,000 to 100,000 volts) let you optimize for different coatings and substrates.

The quality of atomization and spray pattern also affects performance:

- Adjustable atomizing air and fan air controls allow precise control of droplet size and spray width.

- Consistent spray repeatability enhances finish quality, especially important in automated systems.

Compatibility with Coating Materials

Different coatings such as single-pack paints, two-component (2K) coatings, waterborne paints, or powder coatings may require specific gun compatibility.

- Verify the gun's materials and seals are compatible with your intended coatings to prevent corrosion or degradation.

- Some guns offer independent control for materials in single or twin-pack systems.

- Waterborne guns might need isolation systems to handle conductivity safely.

- Automatic electrostatic guns can handle high flow rates, often up to 1000cc/minute, suited for high volume production.

Physical Build and Durability

Durability is crucial in industrial settings where spray guns operate for extended hours or in harsh conditions.

- Select spray guns made with high-quality materials such as stainless steel or aluminum alloy for corrosion resistance.

- Heavy-duty pistons and robust triggers ensure longer life and reliable performance.

- Consider spray guns designed for easy serviceability, such as quick disconnect features that allow rapid replacement or cleaning without dismantling the entire setup.

Automation Compatibility and Installation

Automatic electrostatic spray guns are designed to integrate with traversing machines, robots, or production lines.

- Modular installation systems and manifold styles support hookup to different automation equipment.

- Look for guns that offer easy mounting options and electrical connections.

- Some models have internal power supplies, eliminating external cables and improving safety.

- Consider if the spray gun supports multiple operating modes or is optimized for a specific task.

Safety Features

Because electrostatic spray guns use high voltage, safety measures are critical.

- Ensure the gun has proper insulation and anti-static filters that reduce static hazards.

- Quick disconnect fluid tips prevent operator exposure to hazardous fluids during maintenance.

- Fire hazard reduction features such as compatibility with non-flammable cleaning solvents and safe cleaning procedures are important.

Maintenance and Cleaning

Maintaining cleanliness and proper functioning ensures consistent performance and longer service life.

- The spray gun should be easy to disassemble and clean regularly, ideally within minutes of use or after each painting session.

- Soak parts like triggers, nozzles, and paint cups in compatible cleaning solutions, avoiding flammable sprays.

- Regular use of gun wash and compressed air helps remove dried or caked paint.

- Maintenance-friendly design with easily accessible parts reduces downtime.

Routine Maintenance Steps

- Spray out leftover paint before cleaning.

- Disassemble parts except electrical components.

- Soak and brush to clean hard-to-reach areas.

- Dry and reassemble carefully.

Additional Considerations

Power Source and Mobility

- While most industrial automatic electrostatic guns are fixed and powered via production line systems, some portable models powered by batteries or manual feed systems exist for smaller jobs.

- Choose based on application scale, coating material, and operational environment.

Cost and Warranty

- Automatic electrostatic spray guns vary widely in cost depending on features, compatibility, and durability.

- Consider the total cost of ownership including warranty, cost of consumables, and maintenance.

- Longer warranties often indicate robust design and manufacturer confidence.

Frequently Asked Questions (FAQs)

1. What is the main benefit of using an automatic electrostatic spray gun?

It provides higher transfer efficiency, reducing paint waste and improving finish quality, while enabling faster automated application.

2. Can an automatic electrostatic spray gun be used with waterborne paints?

Yes, but it's best to check if the gun supports waterborne coatings and whether isolation systems are needed to safely handle conductivity.

3. How often should an electrostatic spray gun be cleaned?

Ideally, after every painting job or within 20 minutes of pausing to prevent clogging and maintain spray quality.

4. Are there safety risks with electrostatic spray guns?

High voltage use means proper insulation, grounding, and anti-static measures are critical to prevent shocks and fire hazards.

5. What types of automation equipment are compatible with automatic electrostatic spray guns?

They commonly integrate with traversing machines, robotic arms, and production line manifolds designed for precise, repeatable coating application.

[1] https://binks.com/product/estaquick-automatic-gun/

[2] https://www.alibaba.com/showroom/electrostatic-spray-gun-price.html

[3] https://www.graco.com/us/en/in-plant-manufacturing/products/liquid-coating/spray-booth/spray-guns-applicators/pro-xp-auto.html

[4] https://www.alibaba.com/showroom/electrostatic-spray-gun-parts.html

[5] https://www.patvin.co.in/capabilities-overview/paint-application-system/applicators/guns/automatic-paint-guns/electrostatic-paint-gun/

[6] https://patents.google.com/patent/CN101184555B/zh

[7] https://www.sames.com/usa/en/product-trp-501-automatic-electrostatic-spraygun.html

[8] https://patents.google.com/patent/WO2021012778A1/zh

[9] https://www.sprayequipment.com/products/spray-guns/electrostatic

[10] https://patents.google.com/patent/CN1006447B/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.