Content Menu

● Introduction to Electrostatic Spray Guns

>> What is an Automatic Electrostatic Spray Gun?

● Fundamentals of Electrostatic Spraying

>> Electric Charge and Electrostatic Forces

>> Coulomb Force in Electrostatic Spraying

● Core Components of an Automatic Electrostatic Spray Gun

>> 1. High-Voltage Power Supply

>> 2. Charging Electrode

>> 3. Atomizing Nozzle

>> 4. Fluid Supply and Control System

>> 5. Grounding System

● Working Principle in Detail

>> Step 1: Atomization

>> Step 2: Electrostatic Charging

>> Step 3: Particle Repulsion and Dispersion

>> Step 4: Attraction Toward the Workpiece

>> Step 5: Deposition and Adhesion

● Automatic Control and Operation

>> Integration with Automation Systems

>> Real-Time Monitoring

>> Feedback Control

● Advantages of Automatic Electrostatic Spray Guns

● Applications of Automatic Electrostatic Spray Guns

>> Automotive Industry

>> Electronics and Appliances

>> Furniture and Woodworking

>> Manufacturing and Heavy Industry

>> Powder Coating

● Challenges and Considerations

● Conclusion

● Frequently Asked Questions

Electrostatic spray guns have become a cornerstone technology in modern industrial coating and painting applications due to their efficiency and ability to provide uniform coverage with minimal waste. This article delves deeply into the working principle of automatic electrostatic spray guns, explaining their core components, electrostatic theory, atomization mechanisms, control systems, advantages, and their applications in various industries.

Introduction to Electrostatic Spray Guns

Electrostatic spray guns apply coatings by electrically charging the paint or powder particles and directing them toward a grounded target. The resulting electrostatic attraction improves transfer efficiency by pulling the charged particles onto the object and reducing overspray.

What is an Automatic Electrostatic Spray Gun?

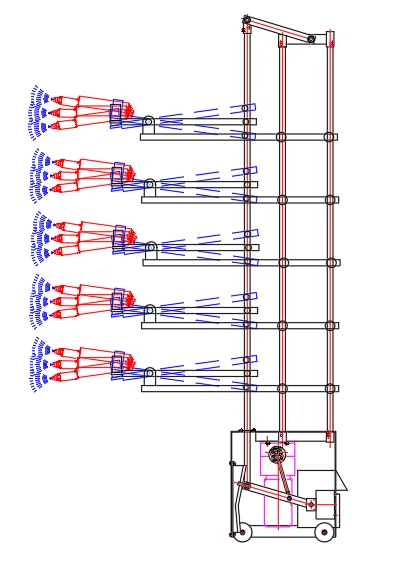

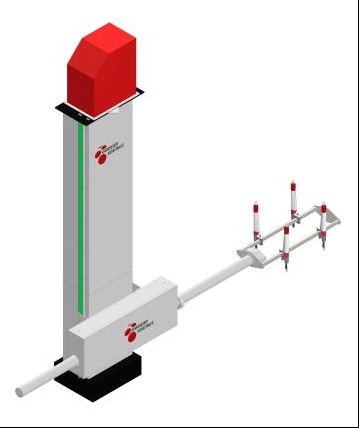

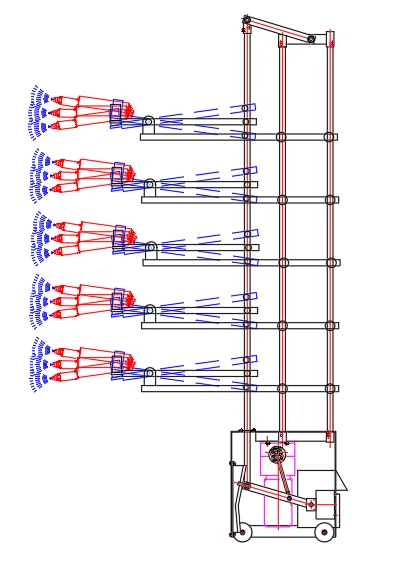

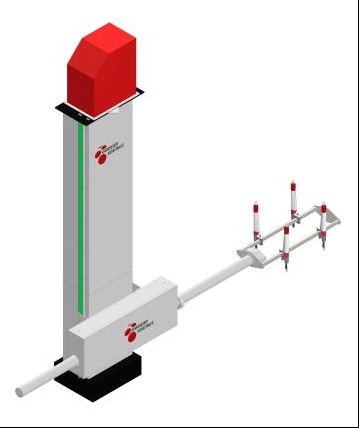

An automatic electrostatic spray gun integrates electrostatic charging technology with automated operation controls. This combination allows continuous, precise spraying in industrial production lines, minimizing manual input and human error. The spray guns are mounted on robotic arms, conveyors, or gantry systems depending on the application.

Fundamentals of Electrostatic Spraying

Understanding the working principle requires familiarity with basic electrostatic theory as well as fluid atomization physics.

Electric Charge and Electrostatic Forces

All matter contains charged particles - electrons (negative) and protons (positive). The electrostatic spray gun charges liquid or powder particles by passing them through or near a high voltage electrical field, typically negative in polarity. When these charged particles approach a grounded or positively charged object, an attractive force pulls them to the surface.

- Like charges repel; opposite charges attract.

- By charging the coating particles negatively, and grounding the target part (positive charge or neutral), particles are drawn toward the surface, improving adhesion.

Coulomb Force in Electrostatic Spraying

The Coulomb force - the electrostatic attraction/repulsion between charged bodies - is the key driver behind particle trajectory and deposition.

The spray gun generates a strong electric field using a high voltage power supply connected to an electrode within the gun. The charged particles experience acceleration toward the grounded part under this force, overcoming gravity and air resistance.

Core Components of an Automatic Electrostatic Spray Gun

1. High-Voltage Power Supply

The source of the electrostatic charge, typically operating in the range of tens to hundreds of kilovolts, providing the necessary voltage to create the electric field for particle charging.

2. Charging Electrode

Located close to the spray nozzle, this component imparts a high voltage charge to the atomized droplets or powder particles leaving the gun.

3. Atomizing Nozzle

The nozzle disperses the fluid or powder into fine particles or droplets. It often uses compressed air for atomization, breaking the liquid into a mist or powder into fine particles.

4. Fluid Supply and Control System

Includes pumps, valves, and sensors to regulate the flow rate and pressure of the coating material. Automation systems coordinate spray parameters with production conditions.

5. Grounding System

The target object is grounded or held at a positive potential to create a potential difference with the charged spray, ensuring attraction.

Working Principle in Detail

Step 1: Atomization

The coating material, either liquid paint or powder, is supplied to the spray gun. The atomizing nozzle uses compressed air or hydraulic pressure to break the material into tiny droplets or fine powder particles.

Step 2: Electrostatic Charging

As particles exit the nozzle, they pass by or through an electrode charged at high voltage. This electrode imparts a negative charge to the particles via corona discharge or contact charging.

- Corona discharge creates a region of ionized air near the electrode, with free electrons attaching to particles.

- The charged particles attain a high surface charge density.

Step 3: Particle Repulsion and Dispersion

Since similarly charged particles repel each other, they disperse evenly in the spray plume, preventing clumping and promoting uniform coverage.

Step 4: Attraction Toward the Workpiece

The grounded or positively charged workpiece creates an electric field that attracts the negatively charged particles. This results in:

- Enhanced transfer efficiency: more coating reaches the target.

- Reduced overspray and coating waste.

- Improved wrapping effect: coating reaches hidden or shadowed surfaces due to electric field lines.

Step 5: Deposition and Adhesion

The coating particles adhere firmly to the surface due to electrostatic forces and mechanical bonding. In powder coating, particles may be heated and melted to form a continuous film.

Automatic Control and Operation

Integration with Automation Systems

Automatic electrostatic spray guns are connected to production line control systems and robotic arms that move and adjust spray parameters dynamically for consistent coating quality.

Real-Time Monitoring

Sensors monitor:

- Voltage levels

- Spray pressure and flow rates

- Particle charge (sometimes measured indirectly)

- Gun-to-part distance

Feedback Control

Adjustments are made in real-time using PID controllers or AI-driven systems to optimize spray quality and efficiency.

Advantages of Automatic Electrostatic Spray Guns

- High transfer efficiency: Up to 90% or more of coating material reaches the target, minimizing waste.

- Uniform coating thickness: Electrostatic forces help achieve even distribution and reduce runs or sags.

- Reduced overspray and pollution: Less coating material lost to environment.

- Improved adhesion and finish quality: Electrostatic attraction enhances surface coverage, even in difficult geometries.

- Increased production speed: Automation allows faster cycle times and less manual labor.

- Material savings: Less paint or powder consumption reduces cost.

Applications of Automatic Electrostatic Spray Guns

Automotive Industry

Used extensively for applying primers, base coats, and clear coats on car bodies with high precision.

Electronics and Appliances

Coating of housings, metal parts, and components for protection and aesthetics.

Furniture and Woodworking

Spraying lacquers and varnishes evenly over wood surfaces.

Manufacturing and Heavy Industry

Protective coatings on machinery, aerospace components, and metal structures to prevent corrosion.

Powder Coating

Commonly used in industrial finishing for durable, uniform powder application before baking.

Challenges and Considerations

- Safety: High voltage requires proper insulation and grounding procedures.

- Faraday Cage Effect: Electrostatic paint may miss recessed or enclosed areas due to electric field shielding.

- Distance Regulation: Too close creates electrical grounding that reduces charging; too far causes paint to miss target or settle on the operator.

- Material Limitations: Some coating materials do not charge well electrostatically.

- Maintenance: Nozzle clogging and electrode wear affect performance.

Conclusion

Automatic electrostatic spray guns leverage the fundamental principles of electrostatics combined with modern automation to deliver efficient, uniform, and cost-effective coating solutions. Understanding how electric charges, Coulomb forces, and atomization mechanisms interplay provides the basis for optimizing these devices in various industrial coating applications.

Frequently Asked Questions

1. How does the electrostatic charge improve paint transfer efficiency in automatic spray guns?

Electrostatic charge makes paint particles negatively charged while the target is grounded or positively charged, creating an attractive force that pulls particles to the surface, resulting in higher transfer efficiency and less overspray.

2. What is the role of the high voltage power supply in an electrostatic spray gun?

It generates the high voltage required to charge the electrode, which in turn imparts electrical charges to the spray particles.

3. Why is grounding the target object important in electrostatic spraying?

Grounding creates a potential difference, attracting charged particles to the surface and ensuring effective coating deposition.

4. Can electrostatic spray guns be used with both liquid paint and powder coatings?

Yes, they can charge and spray both liquids and powder, making them versatile for different coating types.

5. What precautions are necessary for safety when using electrostatic spray guns?

Proper grounding, insulation, maintaining safe distances, and avoiding flammable environments are crucial due to the high voltage and electrostatic fields involved.

[1] https://www.powderspraymachine.com/electrostatic-spraying-coating-principle/

[2] https://patents.google.com/patent/CN1006447B/zh

[3] https://roboticpaint.com/electrostatic-spray-gun-guide/

[4] https://ascelibrary.org/doi/10.1061/(ASCE)EY.1943-7897.0000763

[5] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/electrostatic-spray-gun-basics.html

[6] https://patents.google.com/patent/WO2021012778A1/zh

[7] https://www.youtube.com/watch?v=h3zbxTAFKtY

[8] https://patents.google.com/patent/CN101184555B/zh

[9] https://www.youtube.com/watch?v=vcVYfVoXAC8

[10] https://patents.google.com/patent/CN1192168A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.