Content Menu

● Introduction

● What Is Powder Coating?

>> Key Benefits of Powder Coating

● The Evolution of Electrostatic Spray Technology

>> Manual vs. Automatic Electrostatic Spray Guns

● How Do Automatic Electrostatic Spray Guns Work?

● Advantages of Automatic Electrostatic Spray Guns

>> Unmatched Efficiency and Productivity

>> Enhanced Finish Quality

>> Reduced Material Waste

>> Improved Worker Safety and Ergonomics

>> Lower Operational Costs

● Industry Use Cases and Success Stories

>> Automotive Parts Manufacturing

>> Home Appliances

>> Metal Furniture and Fixtures

>> Aerospace and Defense

● Integration With Modern Production Lines

>> Robotics and Automation

>> Quality Control Systems

>> Customization and Flexibility

● Challenges and Considerations

>> Upfront Investment

>> System Complexity

>> Maintenance

>> Training

● Future Trends and Innovations

>> Smart, Connected Systems

>> Sustainable Manufacturing

>> Compact Modular Designs

>> Advanced Powder Coating Materials

● Conclusion

● Frequently Asked Questions

Introduction

In the rapidly evolving world of industrial finishing, powder coating has emerged as a preferred method for delivering superior, durable finishes across a variety of metals and components. At the heart of this technological evolution is the automatic electrostatic spray gun—a device that has revolutionized the application process, leading to significant improvements in efficiency, finish quality, and cost-effectiveness. This article explores why automatic electrostatic spray guns are regarded as true game-changers for powder coating operations.

What Is Powder Coating?

Powder coating is a finishing process where dry powder—typically composed of resins, pigments, and other additives—is electrostatically applied to a surface and then cured under heat to form a strong, protective layer. Known for its superior durability, environmental benefits, and vibrant finish, powder coating is used in automotive, appliance, architecture, and many other industries.

Key Benefits of Powder Coating

Powder coating offers:

- Greater durability compared to liquid paints.

- Resistance to chipping, scratching, and corrosion.

- Minimal environmental impact, as it emits no volatile organic compounds (VOCs).

- Diverse color and texture options.

The Evolution of Electrostatic Spray Technology

The heart of modern powder coating efficiency lies in applying the coating uniformly and efficiently. This challenge led to the adoption of electrostatic spray technology.

Manual vs. Automatic Electrostatic Spray Guns

While manual spray guns require skilled operators for effective application, automatic electrostatic spray guns use advanced controls, robotics, and consistent spray patterns to ensure a higher degree of uniformity, especially for complex or high-volume applications.

How Do Automatic Electrostatic Spray Guns Work?

Automatic electrostatic spray guns use an electrical charge to attract powder particles to grounded workpieces. Here's how it unfolds:

- Powder Loading: The spray gun draws powder from a hopper.

- Atomization: The powder is fluidized into a fine mist.

- Charging: As powder exits the gun, it encounters a high-voltage electrode, becoming charged.

- Attraction: The charged powder is attracted to the grounded substrate, wrapping around the workpiece for even coverage.

- Curing: The coated part is then moved to an oven, where the powder melts and forms a hard, uniform finish.

Advantages of Automatic Electrostatic Spray Guns

Automatic electrostatic spray guns provide a suite of advantages that set them apart from manual systems. Let's explore why these devices are transforming the powder coating industry.

Unmatched Efficiency and Productivity

One of the most significant benefits is the boost in throughput and efficiency. Automatic spray systems can operate continuously, delivering consistent application rates that dramatically outpace manual systems. With programmable patterns and robotic arms, they can handle high production volumes or complex geometries with minimal downtime.

- Reduced Cycle Times: Automatic systems coat more parts per hour due to faster, uninterrupted operation.

- Minimal Rework: Precision application means fewer defects, reducing the need for touch-ups or re-sprays.

- Consistent Film Thickness: Automated controls ensure uniform coverage, key for product performance and aesthetics.

Enhanced Finish Quality

Consistency is king in powder coating, particularly for industries like automotive and electronics where tolerances are tight.

- Uniform Coverage: Electrostatic attraction ensures powder wraps around every contour, reducing missed spots or over-application.

- Superior Surface Finish: Automatic guns deliver smoother, more attractive coatings with fewer visible defects.

- Reproducibility: Programmed spray patterns mean the same quality, every batch.

Reduced Material Waste

Powder reclaim and high transfer efficiency are hallmarks of automatic electrostatic spray systems.

- High Transfer Efficiency: Electrostatic charge ensures more powder adheres to the part, not wasted as overspray.

- Recycling Overspray: Unused powder can often be collected and reused, driving down material costs and waste.

- Lower Environmental Impact: Less waste means less impact on the environment and easier compliance with regulations.

Improved Worker Safety and Ergonomics

With automatic systems, workers spend less time in hazardous environments.

- Reduced Exposure: Operators are not consistently handling spray guns or near the application zone.

- Minimized Repetitive Tasks: Automation lessens the risk of strain or injury.

- Cleaner Workplace: Fewer airborne particles escape due to the efficiency of automated enclosures.

Lower Operational Costs

Though the initial investment in automatic spray guns and robotics can be substantial, the cost savings over time are significant.

- Lower Labor Costs: Fewer skilled technicians are needed to operate or supervise automated systems.

- Energy Efficiency: Faster application and fewer defects mean less energy used per finished part.

- Maintenance Savings: Consistent operation results in less frequent breakdowns or maintenance downtime.

Industry Use Cases and Success Stories

Industries adopting automatic electrostatic spray guns have reported impressive results:

Automotive Parts Manufacturing

Automotive suppliers deal with strict specifications for corrosion resistance and appearance. Automatic spray guns ensure complex parts—like engine components and wheels—receive an even, durable coat, streamlining production and meeting industry standards.

Home Appliances

From refrigerators to ovens, a consistent finish is essential. Automation in powder coating allows appliance makers to produce high volumes with fewer defects, shorter cycle times, and lower waste.

Metal Furniture and Fixtures

Office furniture, shelving, and metal fixtures benefit from the versatility of programmable automatic spray guns, which handle diverse shapes and sizes with precise coating thickness.

Aerospace and Defense

Precision and durability are critical. Automatic electrostatic spray guns deliver coatings that withstand harsh conditions and meet rigorous industry regulations.

Integration With Modern Production Lines

Automatic electrostatic spray guns fit seamlessly into today's smart manufacturing environments.

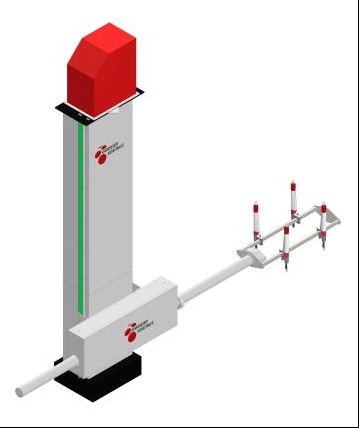

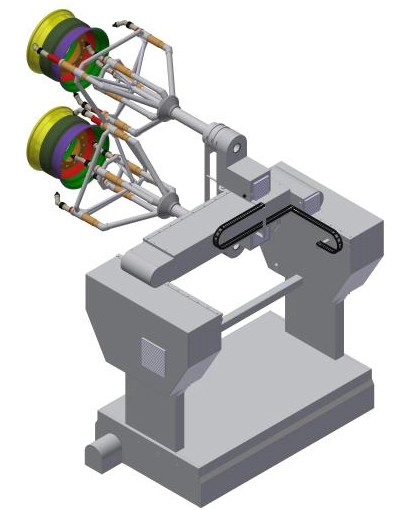

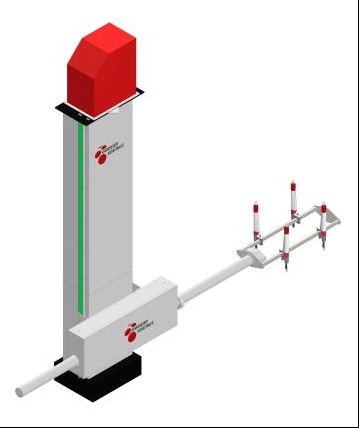

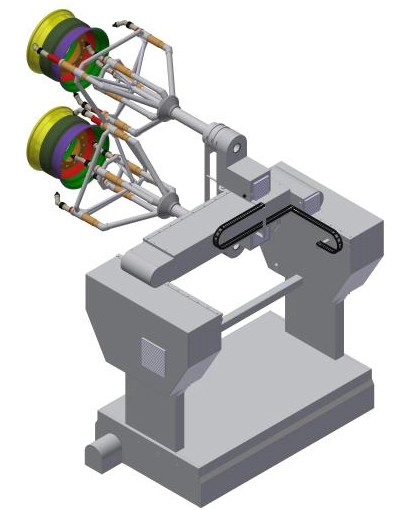

Robotics and Automation

Robotic arms equipped with electrostatic guns can be programmed for repetitive, precise movement, increasing throughput and minimizing human error.

Quality Control Systems

Modern systems feature real-time monitoring, ensuring constant oversight of spray parameters, powder usage, and finish quality. Automated feedback can adjust spray patterns on-the-fly for optimal results.

Customization and Flexibility

Advanced programming allows manufacturers to change spray patterns or recipes quickly, accommodating custom orders or varied product lines without downtime for manual adjustments.

Challenges and Considerations

Though automatic electrostatic spray guns bring tremendous advantages, their successful implementation requires careful attention.

Upfront Investment

The initial cost is higher than manual systems, encompassing not just the guns themselves but also robotics, controls, and safety enclosures. However, return on investment is typically rapid due to savings in labor, materials, and energy.

System Complexity

Automated systems are more complex, requiring skilled technical staff for setup, calibration, and maintenance to avoid downtime or quality issues.

Maintenance

Ongoing maintenance—such as cleaning, calibration, and occasional replacement of electrodes and other components—is crucial to avoid costly malfunctions.

Training

Operators must be trained not only in system operation but also in troubleshooting and process optimization.

Future Trends and Innovations

The evolution of powder coating is far from over. Here's what the future holds for automatic electrostatic spray guns:

Smart, Connected Systems

Industry 4.0 is bringing smarter, more connected systems that collect data and self-optimize, ensuring peak efficiency and traceability across the entire production process.

Sustainable Manufacturing

As environmental standards become more stringent, advances in powder formulations and spray technologies will drive even higher material efficiencies and cleaner processes.

Compact Modular Designs

Emerging automatic guns are becoming more compact and modular, allowing easier integration into diverse production environments and enabling flexible manufacturing setups.

Advanced Powder Coating Materials

New powder chemistries offer improved wear resistance, expanded color options, and specialty features like antimicrobial protection, further broadening application areas.

Conclusion

Automatic electrostatic spray guns have redefined what's possible in powder coating. From accelerating production and improving finish quality to reducing costs and enhancing worker safety, these systems are a testament to the transformative power of modern manufacturing technology. As industries continue to strive for even greater efficiency and sustainability, the role of automated powder coating systems will only grow in importance.

Frequently Asked Questions

1. What is the difference between manual and automatic electrostatic spray guns?

Manual spray guns require skilled operators to apply powder, which can result in inconsistencies and slower throughput. Automatic spray guns use robotics and programmable controls to deliver uniform, high-speed application with minimal human intervention.

2. How does electrostatic spraying improve powder coating efficiency?

Electrostatic spraying charges the powder particles, causing them to adhere to grounded parts and wrap around complex geometries, which increases transfer efficiency and reduces waste.

3. Can automatic electrostatic spray systems handle different part shapes and sizes?

Yes, most modern automatic systems are highly programmable and can adapt to a wide variety of shapes and sizes, allowing for flexible manufacturing.

4. Is the investment in automatic electrostatic spray guns worthwhile?

Although the initial cost is higher, most companies experience significant long-term savings in labor, material, and energy, leading to rapid returns on investment.

5. What industries benefit most from automated powder coating?

Automotive, appliance, metal furniture, aerospace, and electronics are leading beneficiaries, but virtually any industry requiring durable, high-quality coatings can benefit.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.