Content Menu

● Understanding Powder Coating and Spray Gun Units

>> What Is Powder Coating?

>> The Role of Spray Guns in Powder Coating

● Advantages of Advanced Spray Gun Units

>> Improved Powder Transfer Efficiency

>> Faraday Cage Penetration Capability

>> Consistent and Uniform Spray Patterns

>> Energy and Dust Savings

>> Versatile Application Across Powder Types

● Operational Benefits

>> Increased Productivity and Reduced Downtime

>> Integration with Automated Systems

>> Real-Time Monitoring and Adjustability

● Business and Environmental Impact

>> Cost Savings and Return on Investment

>> Enhanced Quality and Customer Satisfaction

>> Environmental Compliance and Safety

● Key Features to Look for in an Advanced Powder Coating Spray Gun

● Conclusion: Why Upgrade to an Advanced Powder Coating Spray Gun?

● Frequently Asked Questions (FAQ)

Powder coating is a widely used finishing process that offers durable, high-quality, and environmentally friendly protection for a variety of metal and other substrates. One of the most critical components in a powder coating line is the spray gun unit. Choosing an advanced spray gun unit can significantly improve the efficiency, quality, and economics of your powder coating operations. This article explores why investing in a sophisticated powder coating spray gun unit is essential for modern coating lines. It covers the technical advantages, operational efficiencies, and business benefits that come with advanced spray gun technology.

Understanding Powder Coating and Spray Gun Units

What Is Powder Coating?

Powder coating involves applying dry, fine powdered particles that are electrostatically charged onto a grounded workpiece. The charged powder particles adhere to the surface, and then the coated parts are cured in an oven to form a continuous, durable finish. Unlike liquid paint, powder coating produces a thicker, more resilient layer without the need for solvents, reducing volatile organic compound (VOC) emissions.

The Role of Spray Guns in Powder Coating

Spray guns are devices that apply the electrostatically charged powder onto the workpiece. They fluidize the powder from a hopper, charge the particles using high voltage, and spray a cloud of powder onto the target. The effectiveness of the spray gun in creating an even, consistent, and efficient coating is crucial for the overall finish quality and powder usage efficiency.

Advantages of Advanced Spray Gun Units

Improved Powder Transfer Efficiency

Advanced powder coating guns implement cutting-edge technologies to optimize powder transfer efficiency — the amount of powder that actually adheres to the part versus what is wasted as overspray. Technologies like Transfer Electronic Control (TEC) enable automatic self-adjustment of electrostatic charge to optimize powder flow and charging based on powder type, flow rate, and part distance.

Enhanced transfer efficiency reduces powder waste, lowers material consumption costs, and helps maintain a cleaner working environment by minimizing airborne powder dust. It also means more consistent coating thickness and fewer touch-ups, which improves throughput.

Faraday Cage Penetration Capability

Certain complex parts feature recesses and corners known as Faraday cage areas where electrostatic charge builds up and repels powder particles, leading to uneven coating. Advanced spray guns have superior Faraday cage penetration capabilities that ensure powder is effectively deposited even in these difficult-to-coat geometries. This results in complete coverage and eliminates the need for manual touch-ups in hidden areas.

Consistent and Uniform Spray Patterns

Advanced spray guns are engineered to produce constant stable spray patterns that deliver smooth and even application across the workpiece surface. Balanced and ergonomic design improves operator comfort and control, reducing fatigue during long production runs and contributing to uniform coating films—key for both aesthetic and protective qualities.

Energy and Dust Savings

Innovation in spray gun design focuses on reducing energy consumption while maintaining performance. Incidents of dust generation are minimized by refined powder flow and electrostatic control, preventing excess powder from becoming airborne without achieving deposition. This not only cuts operational costs but also promotes safer working conditions by controlling dust exposure.

Versatile Application Across Powder Types

Modern spray gun units accommodate various powder chemistries including polyester, epoxy, acrylic, and hybrid powders. They adjust automatically to variations in powder flow characteristics, allowing users to switch between different powder types or colors without major equipment recalibration. This versatility supports varied production demands and quick color or product changes.

Operational Benefits

Increased Productivity and Reduced Downtime

Advanced spray gun units are designed with features such as easy-to-clean components and modular construction that reduce maintenance time. Reliable and precise powder delivery reduces the frequency of recalibration and knockdown procedures. As a result, overall line uptime increases and production schedules remain stable.

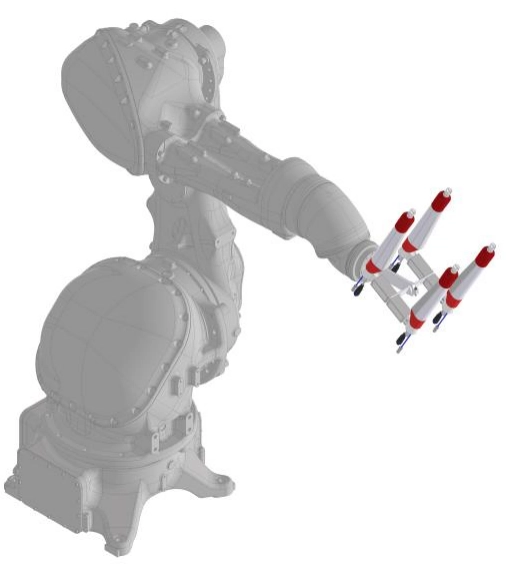

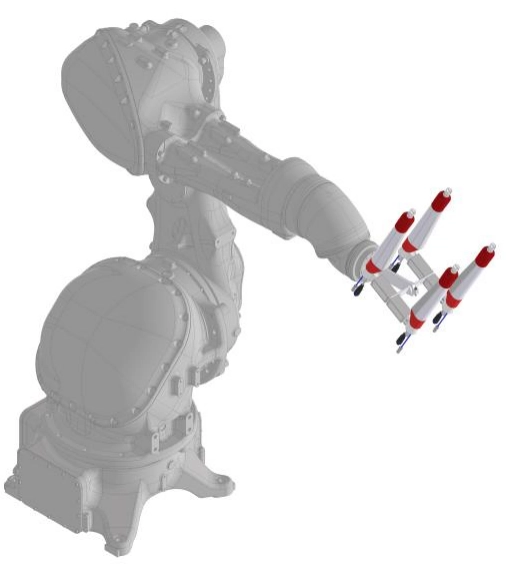

Integration with Automated Systems

Many advanced spray guns support integration with automated coating lines. Features like remote control, communication interfaces, and programmable spraying parameters enable seamless operation within automated booths or robotic systems. This level of control enhances repeatability and quality while reducing labor requirements.

Real-Time Monitoring and Adjustability

Some advanced spray gun systems come equipped with digital control units that provide real-time feedback on parameters like voltage, air pressure, and powder feed rate. Operators can fine-tune these settings on the fly to adapt to specific parts or production conditions, optimizing coating quality without stopping the line.

Business and Environmental Impact

Cost Savings and Return on Investment

Although advanced powder coating spray guns represent a higher upfront investment compared to basic models, the cost savings generated from improved powder transfer efficiency, reduced waste, lower energy consumption, and higher throughput provide a strong return on investment. By extending the life of consumables and reducing rework, these units help keep costs predictable and manageable.

Enhanced Quality and Customer Satisfaction

Consistent finish quality with excellent color uniformity, surface smoothness, and durable coverage reduces customer complaints and warranty costs. The ability to deliver a high-quality finish with fewer defects helps attract and retain clients, potentially opening new market opportunities.

Environmental Compliance and Safety

Advanced spray units contribute to greener manufacturing by reducing powder waste and minimizing airborne contaminants. This supports compliance with increasingly strict environmental regulations and protects worker health by controlling dust exposure. Energy-efficient designs also reduce the carbon footprint of powder coating operations.

Key Features to Look for in an Advanced Powder Coating Spray Gun

- High Voltage Control: Precise and adjustable high voltage application for optimal electrostatic charging.

- Ergonomic Design: Balanced, lightweight construction to reduce operator fatigue.

- Powder Flow Regulation: Adjustable powder feed and spray pattern control for consistent application.

- Automatic Charge Adjustment: Technology like TEC for self-regulating charging based on conditions.

- Compatibility: Ability to handle a wide range of powder types and particle sizes.

- Easy Maintenance: Modular parts and easy cleaning features.

- Digital Interface: User-friendly controls and monitoring for real-time adjustment.

Conclusion: Why Upgrade to an Advanced Powder Coating Spray Gun?

Investing in an advanced spray gun unit elevates your powder coating line's performance, efficiency, and capability. The benefits span from reduced powder waste and energy savings to superior coating quality and enhanced operator comfort. These combined advantages not only boost your operational profitability but also support compliance with environmental and safety standards. For manufacturers seeking to stay competitive in a demanding market, upgrading to a sophisticated spray gun technology is an essential step toward achieving excellence in powder coating.

Frequently Asked Questions (FAQ)

Q1: How does an advanced spray gun improve powder transfer efficiency?

A1: Advanced spray guns use technologies like self-adjusting electrostatic charge and optimized powder flow to ensure more powder adheres to the part, reducing waste and overspray.

Q2: Can advanced spray guns handle different powder types easily?

A2: Yes, many modern units are designed to accommodate a wide range of powders (polyester, epoxy, acrylic, hybrid) and adapt automatically to their flow characteristics.

Q3: What does Faraday cage penetration mean in powder coating?

A3: It refers to the spray gun's ability to effectively coat recessed areas or corners where static charge buildup can repel powder particles, ensuring complete coverage.

Q4: Are advanced powder coating spray guns compatible with automated lines?

A4: Yes, they often have digital control interfaces and remote adjustment capabilities that integrate smoothly with robotic and automatic coating systems.

Q5: Is upgrading to an advanced spray gun cost-effective?

A5: Although the initial investment is higher, the savings from reduced powder consumption, faster production, less rework, and energy efficiency typically provide a favorable return on investment.

[1] https://www.sames.com/usa/en/product-inogun-M.html

[2] https://patents.google.com/patent/CN109675732B/zh

[3] https://www.parkerionics.com/powder-coating-equipment/powder-coating-guns.html

[4] https://patents.google.com/patent/CN113042284B/zh

[5] https://www.sames.com/usa/en/product-inocart-VT.html

[6] https://patents.google.com/patent/CN111604210B/zh

[7] https://advancedplatingtech.com/blog/advantages-of-powder-coating-over-wet-spray-painting-what-you-need-to-know/

[8] https://patents.google.com/patent/CN110508422A/zh

[9] https://www.rapidcoat.com/powder-coating-advanced-application

[10] https://patents.google.com/patent/CN101417274A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.