Content Menu

● What Is a Spray Gun Unit?

● How Does a Spray Gun Unit Work in Powder Coating?

>> Powder Preparation and Fluidization

>> Electrostatic Charging of Powder Particles

>> Spray and Powder Transport

>> Adhesion and Coating Formation

>> Curing Process

● Key Components of a Powder Coating Spray Gun Unit

>> Powder Hopper and Fluidizing System

>> Spray Gun Body and Nozzle

>> Electrostatic Charge Electrode

>> Compressed Air System

>> Control Unit

● Types of Spray Guns in Powder Coating

>> Corona Spray Guns

>> Tribo Spray Guns

>> Electrostatic Disc Spray Guns

● Advantages of Using a Spray Gun Unit in Powder Coating

● Common Operational Considerations

● Frequently Asked Questions (FAQs)

Powder coating is a popular finishing process widely used in industries ranging from automotive to household appliances due to its durability, environmental friendliness, and attractive finish. At the heart of this process is the spray gun unit, a sophisticated tool designed to apply powdered coating materials efficiently and evenly onto surfaces. Understanding what a spray gun unit is and how it functions in powder coating is essential for anyone involved in manufacturing, painting, or finishing applications.

What Is a Spray Gun Unit?

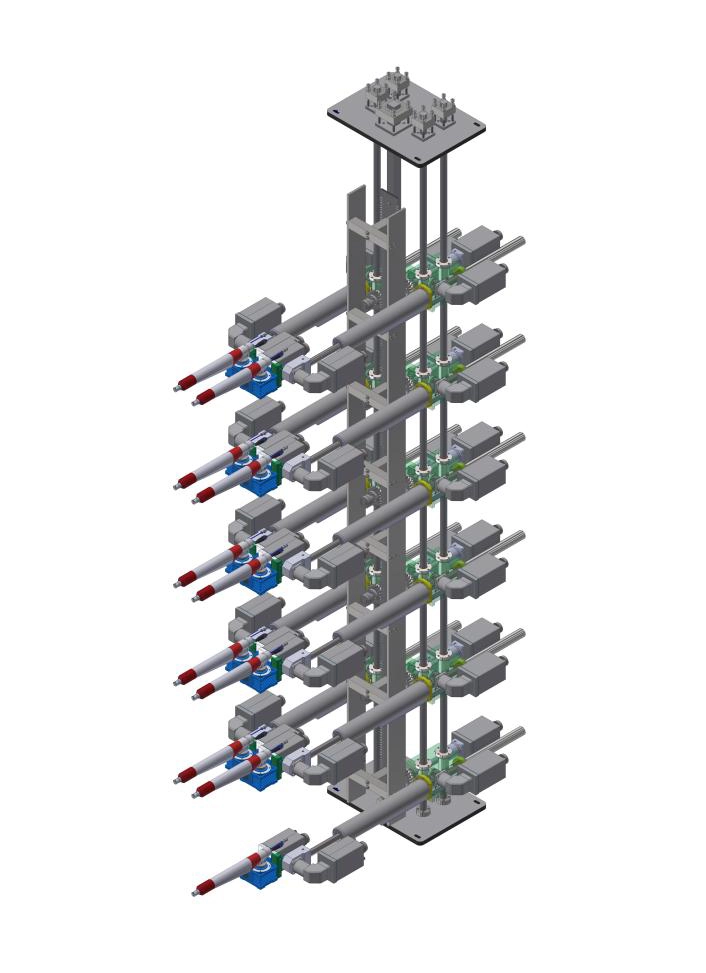

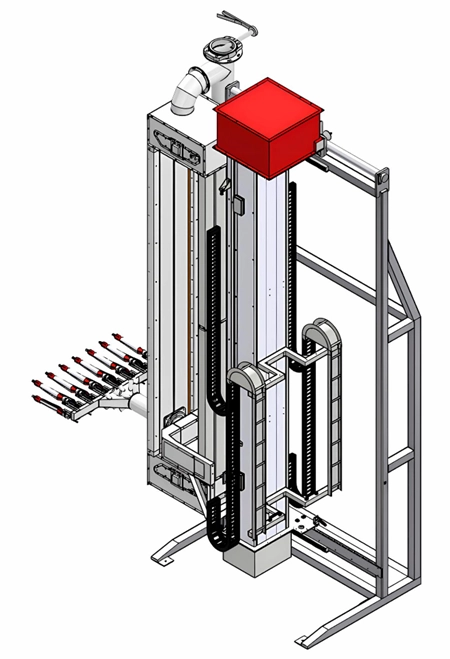

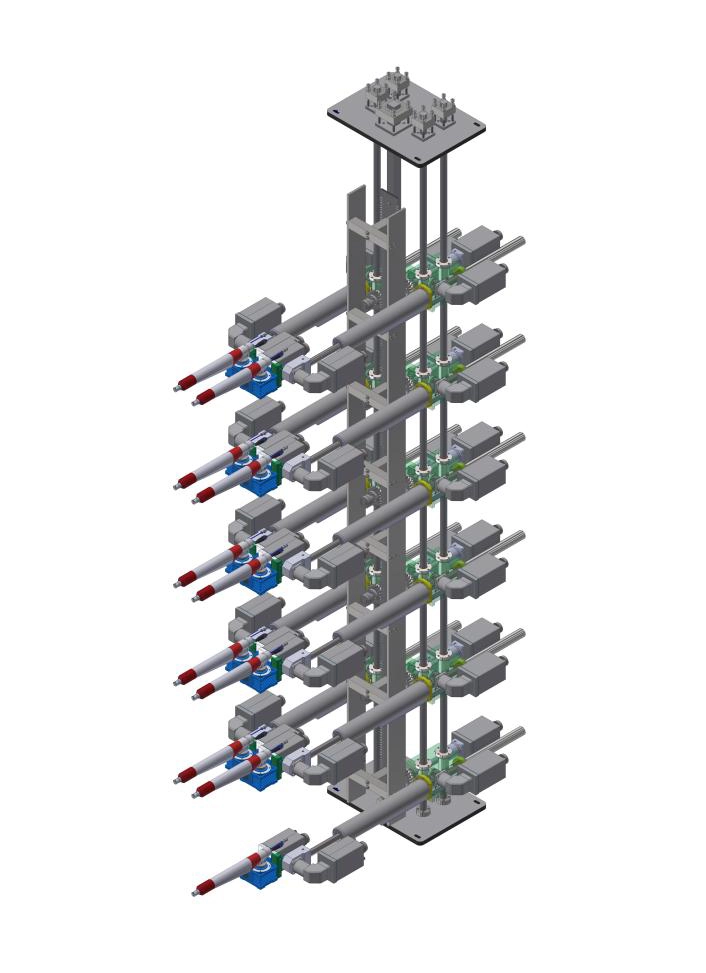

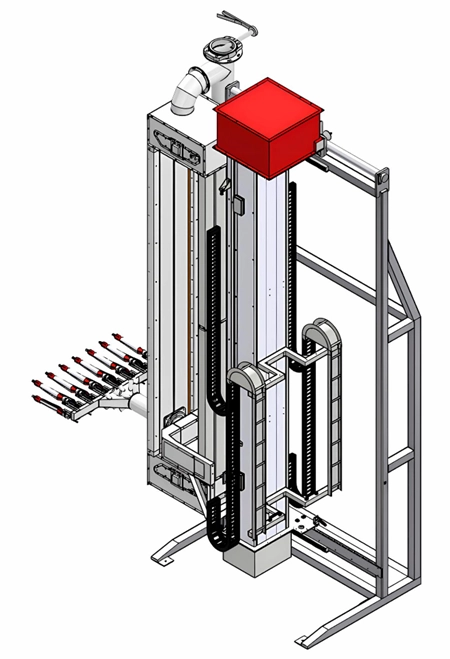

A spray gun unit in powder coating is a device that atomizes and electrostatically charges powder particles, then sprays them onto a grounded workpiece or substrate to form a uniform coating layer. This unit typically consists of several key components:

- Powder hopper or fluidized bed: Holds and fluidizes the powder coating material, turning powder particles into a flowable form.

- Spray gun body: The handheld or mounted dispenser that directs the powder spray toward the workpiece.

- Charging electrode: Imparts an electrostatic charge on the powder particles.

- Compressed air supply: Propels the powder out of the gun and onto the surface.

- Control unit: Adjusts and monitors parameters such as powder flow rate, air pressure, and electrostatic voltage.

Together, these elements control the efficiency, quality, and precision of the powder coating application.

How Does a Spray Gun Unit Work in Powder Coating?

The spray gun unit works through a coordinated system of powder preparation, electrical charging, spraying, and adhesion driven by electrostatic forces and compressed air. Below is a detailed breakdown of the process.

Powder Preparation and Fluidization

Before spraying, the powder coating material is first loaded into the hopper or fluidized bed attached to the spray gun system. In the fluidized bed, air is injected to "fluidize" the powder particles, meaning the powder behaves more like a liquid. This helps separate the particles to avoid clumping and ensures smooth conveyance through the system.

The fluidized state improves powder transport through hoses and ensures consistent feeding into the spray gun.

Electrostatic Charging of Powder Particles

One of the unique features of powder coating spray guns is their ability to impart an electrostatic charge, typically a negative charge, onto the powder particles. This charging most commonly occurs via corona charging, where a high-voltage power supply creates a strong electrostatic field near an electrode at the gun's tip.

As powder particles pass through this field, they pick up a negative charge. Alternatively, some systems use triboelectric charging, where powder gains charge by rubbing against specially designed surfaces in the gun.

Spray and Powder Transport

The charged powder particles are carried by compressed air through the gun's nozzle and sprayed toward the workpiece. The compressed air ensures particles are directed accurately and at the necessary velocity to cover the surface evenly.

The workpiece is grounded electrically, meaning it carries a positive charge or is neutral but connected to earth ground. This polarity difference causes the negatively charged powder particles to be attracted to the grounded surface.

Adhesion and Coating Formation

Thanks to the electrostatic attraction, powder particles adhere uniformly to the surface, forming an even coating. The charged powder naturally wraps around complex shapes due to a phenomenon known as the Faraday cage effect, where particles are drawn to edges and recesses.

The coating thickness gradually builds as more powder particles reach and stick to the surface. However, as the layer thickens, repelling forces between like-charged powder particles grow, eventually stopping further deposition beyond a certain thickness.

Curing Process

The coated workpiece is then transferred to a curing oven and heated to a temperature where the powder melts, flows, and chemically crosslinks to form a continuous, hard, and durable finish. This curing step also ensures that the powder bonds firmly to the substrate.

Key Components of a Powder Coating Spray Gun Unit

Powder Hopper and Fluidizing System

The hopper stores the powder coating material. To maintain a steady flow, many systems include an air injection mechanism that fluidizes the powder, reducing clumps and promoting consistent feed rate.

Spray Gun Body and Nozzle

The spray gun houses internal channels for the powder and air to mix and exit through the nozzle. Different nozzles are available depending on the shape and size of the object to be coated, providing control over spray pattern and coverage.

Electrostatic Charge Electrode

The electrode, often a fine needle or wire, is located near the gun's exit. It is connected to a high-voltage power supply that creates the corona discharge necessary to charge the powder.

Compressed Air System

This system uses compressed air to propel powder particles out of the gun. Air pressure and volume are adjustable parameters that affect particle velocity and spray efficiency.

Control Unit

Modern powder coating spray systems include an electronic control unit that regulates powder feed rate, voltage applied to the electrode, and air parameters. It may include indicators or displays for monitoring system status.

Types of Spray Guns in Powder Coating

Corona Spray Guns

Corona guns use a high-voltage electrode to generate an electrostatic field that charges powder particles negatively. This is the most common method due to its reliability and efficiency.

Tribo Spray Guns

Tribo guns charge powder particles by friction (triboelectric effect) as they pass through Teflon or other non-conductive barrels. The powder receives a positive charge and adheres to the grounded workpiece. Tribo guns avoid some issues faced by corona guns, such as back-ionization and Faraday cage limitations.

Electrostatic Disc Spray Guns

Instead of a typical nozzle, these guns use a spinning disc to fling powder particles outward while charging them electrostatically, suitable for large or flat surfaces.

Advantages of Using a Spray Gun Unit in Powder Coating

- Efficient powder usage: Electrostatic charging reduces overspray and waste, as powder is attracted to the surface rather than dispersed randomly.

- Uniform coating: The charged particles are attracted evenly, even around corners and recesses.

- Environmentally friendly: Powder coating produces little to no volatile organic compounds (VOCs), making it safer and cleaner than liquid painting.

- Durability: The coatings formed through this process are hard, corrosion-resistant, and aesthetically sound.

- Speed and automation: Spray guns can be automated or handheld for versatile application in both mass production and custom jobs.

Common Operational Considerations

- Grounding: It is critical that the workpiece is properly grounded to ensure effective electrostatic attraction.

- Air quality: Compressed air should be clean, dry, and oil-free to prevent defects or clogs in the system.

- Powder type: Different powders may require specific gun types or system settings.

- Maintenance: Regular cleaning and inspection prevent buildup and ensure consistent coating quality.

Frequently Asked Questions (FAQs)

Q1: Why does the powder need to be electrostatically charged before spraying?

A1: The electrostatic charge causes powder particles to be attracted to the grounded workpiece, ensuring even adhesion and reducing overspray and waste.

Q2: Can powder coating spray guns be used on non-metal surfaces?

A2: Powder coating generally requires the substrate to be conductive or properly grounded. For non-metal surfaces, pretreatments or conductive primers might be needed.

Q3: What is the difference between corona and tribo spray guns?

A3: Corona guns charge powder by corona discharge with a high-voltage electrode, typically imparting a negative charge, while tribo guns charge powder by friction, often giving a positive charge. Each method has different powder requirements and application characteristics.

Q4: How is the thickness of the powder coating controlled?

A4: Thickness is controlled by adjusting powder feed rate, spray time, air pressure, and voltage settings on the spray gun system.

Q5: What are common issues if powder doesn't adhere properly?

A5: Common causes include improper grounding of the workpiece, poor powder fluidization or feed, incorrect charging voltage, or contamination on the surface.

[1] https://www.easypowderparts.com/n1895407/How-does-powder-coating-gun-work.htm

[2] https://manuals.plus/zh-CN/hotcoat/71860-100kv-powder-coating-system-manual

[3] https://www.machine4aluminium.com/electrostatic-powder-coating-principle/

[4] https://patents.google.com/patent/CN109675732B/zh

[5] https://en.wikipedia.org/wiki/Powder_coating

[6] https://patents.google.com/patent/CN110508422A/zh

[7] https://www.tiger-coatings.com/us-en/blog/powder-coating-process

[8] https://patents.google.com/patent/CN101184555B/zh

[9] https://metaltech.us/blog/powder-coating-101-how-does-it-work/

[10] https://patents.google.com/patent/CN111604210B/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.