Content Menu

● Understanding Your Automatic Electrostatic Spray Gun

>> What is an Automatic Electrostatic Spray Gun?

>> Key Components of the Spray Gun

● Daily Maintenance Routine for Your Spray Gun

>> Cleaning After Each Use

>> Checking Air and Fluid Lines

● Weekly Maintenance Tasks to Ensure Longevity

>> Deep Cleaning

>> Inspect Electrical Connections

● Monthly Preventive Maintenance

>> Replace Worn Parts

>> Test Electrostatic Charging System

● Troubleshooting Common Issues

>> Inconsistent Spray Pattern

>> Low Electrostatic Charge

>> Paint Spitting or Dripping

● Best Practices for Long-Term Maintenance

>> Use Manufacturer-Recommended Supplies

>> Proper Storage

>> Train Operators

● Safety Considerations

>> Avoid Electrical Shock

>> Prevent Fire Hazards

>> Wear Protective Gear

● Summary

● Frequently Asked Questions (FAQ)

Maintaining an automatic electrostatic spray gun is essential to ensure consistent performance, enhance the lifespan of the equipment, and achieve high-quality spray finishes. Proper care and regular maintenance can prevent common issues such as clogging, uneven spray patterns, and equipment malfunctions. This comprehensive guide will walk you through the steps and best practices for maintaining your automatic electrostatic spray gun for peak performance.

Understanding Your Automatic Electrostatic Spray Gun

Before diving into maintenance, it is important to understand the basic components and operation of your electrostatic spray gun.

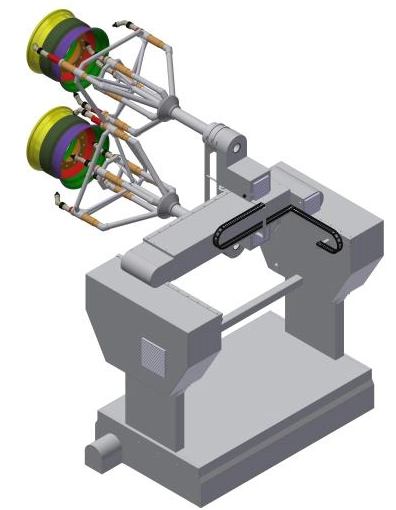

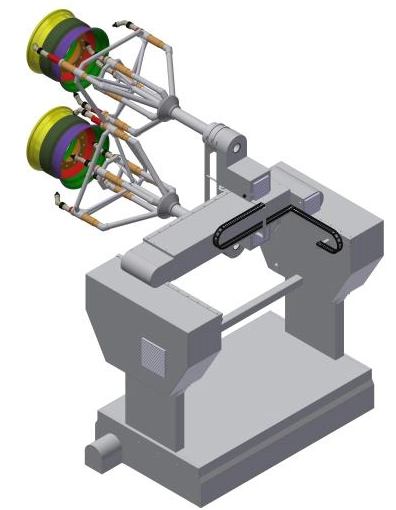

What is an Automatic Electrostatic Spray Gun?

An automatic electrostatic spray gun uses electrostatic charge to atomize paint or coating, which is then attracted to a grounded object, resulting in a smooth and uniform finish. This process reduces overspray and increases transfer efficiency.

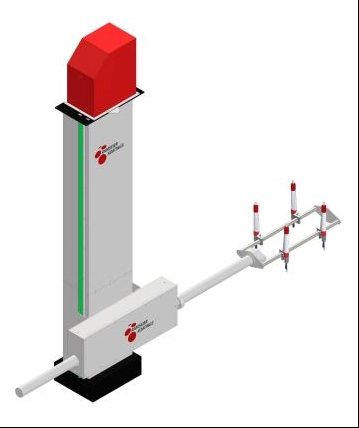

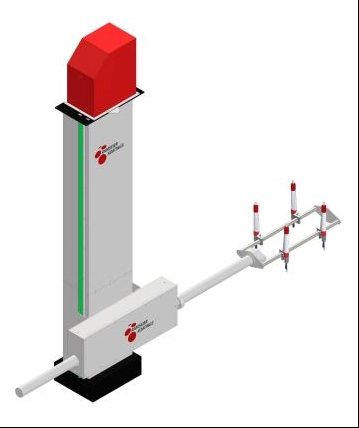

Key Components of the Spray Gun

- Charging Electrode: Creates the electrostatic charge.

- Nozzle: Atomizes the paint into fine droplets.

- Fluid Passage: Channels paint from the reservoir to the nozzle.

- Air Supply: Helps to atomize and propel the paint.

- Trigger or Automatic Control: Activates spraying mechanisms.

Understanding these parts helps in targeted maintenance and troubleshooting.

Daily Maintenance Routine for Your Spray Gun

Consistent daily maintenance prevents buildup and ensures readiness for use.

Cleaning After Each Use

- Flush the System: Immediately flush the fluid passages with an appropriate cleaning solvent to remove residual paint.

- Clean the Nozzle and Electrodes: Use a soft brush or cloth to clean the nozzle and charging electrodes carefully without damaging them.

- Inspect for Wear: Check for any signs of wear, especially on the nozzle or seals, and schedule replacement if necessary.

Checking Air and Fluid Lines

- Ensure the air supply is clean and dry to avoid contaminating the paint.

- Inspect fluid lines for clogs, cracks, or leaks and repair or replace as needed.

Weekly Maintenance Tasks to Ensure Longevity

Weekly checks and maintenance remove deeper build-up and spot potential problems.

Deep Cleaning

- Disassemble Key Parts: Carefully disassemble the nozzle, fluid needle, and air cap to clean thoroughly.

- Ultrasonic Cleaning: For stubborn residues, ultrasonic cleaning devices can be used safely to remove buildup without damaging sensitive components.

- Re-lubricate Moving Parts: Use manufacturer-recommended lubricants on moving or sealing parts to reduce friction and wear.

Inspect Electrical Connections

- Check cables and connectors for wear or corrosion.

- Ensure the grounding system is intact and functioning correctly to maintain electrostatic efficiency.

Monthly Preventive Maintenance

Regular internal checks and replacements keep the spray gun functioning optimally.

Replace Worn Parts

- Replace fluid needles, seals, and nozzles showing signs of wear or erosion.

- Change filters in fluid and air supply lines to prevent blockage.

Test Electrostatic Charging System

- Verify the charging electrode produces the correct voltage.

- Test spray patterns to confirm uniformity and consistent atomization.

Troubleshooting Common Issues

Knowing how to address common problems quickly helps minimize production downtime.

Inconsistent Spray Pattern

- Likely Cause: Clogged nozzle or damaged needle.

- Solution: Clean or replace affected parts and ensure the paint is properly thinned.

Low Electrostatic Charge

- Likely Cause: Faulty charging electrode or poor grounding.

- Solution: Inspect and replace electrodes, confirm grounding connections.

Paint Spitting or Dripping

- Likely Cause: Fluid needle seal failure or incorrect fluid pressure.

- Solution: Replace seals and adjust fluid pressure settings.

Best Practices for Long-Term Maintenance

Adopting professional habits will enhance your gun's life and spray quality.

Use Manufacturer-Recommended Supplies

- Always use compatible cleaning solvents, lubricants, and replacement parts.

- Avoid harsh chemicals that can degrade seals or coatings.

Proper Storage

- Store the spray gun in a clean, dry place.

- Protect delicate parts with caps or covers to prevent dust and damage.

Train Operators

- Ensure all operators are trained in correct operation and maintenance procedures.

- Provide regular refresher sessions to keep best practices top of mind.

Safety Considerations

Electrostatic spray guns operate under high voltage and use flammable materials, so safety is critical.

Avoid Electrical Shock

- Disconnect the gun from the power source before maintenance.

- Use insulated tools and wear proper protective equipment.

Prevent Fire Hazards

- Use paints and solvents in well-ventilated areas.

- Keep flammable materials away from sparks or open flames.

Wear Protective Gear

- Use gloves, eye protection, and masks when handling protective coatings and cleaning solvents.

Summary

Maintaining your automatic electrostatic spray gun requires daily cleaning, weekly deep maintenance, and monthly preventive inspections. By following manufacturer guidelines, regularly replacing worn parts, and troubleshooting promptly, you can ensure consistent spray quality and extend your equipment's life. Prioritize safety during maintenance and operation to protect yourself and your workspace.

Frequently Asked Questions (FAQ)

Q1: How often should I clean my automatic electrostatic spray gun?

A1: Clean your spray gun after every use to prevent paint buildup and clogs. Regular flushing and wiping down are essential for consistent performance.

Q2: What types of solvents are safe to use for cleaning?

A2: Use manufacturer-recommended solvents that are compatible with the paint or coating being used. Avoid harsh chemicals that can degrade seals or internal parts.

Q3: How do I know when to replace parts like nozzles or seals?

A3: Replace parts showing signs of wear, erosion, or damage, such as irregular spray patterns, leaks, or difficulty in fluid control, to maintain quality spraying.

Q4: Can I perform maintenance myself, or should I hire a professional?

A4: Basic cleaning and inspection can be done by trained operators, but complex repairs or electrical testing should be performed by qualified technicians.

Q5: What is the impact of poor grounding on spray performance?

A5: Poor grounding reduces the effectiveness of electrostatic charge, causing uneven coating and increased overspray. Ensuring proper grounding is crucial for optimal operation.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.