Content Menu

● Understanding Automatic Electrostatic Spray Guns

>> What Are Automatic Electrostatic Spray Guns?

>> Applications and Importance

● The Role of Smart Control Systems in Electrostatic Spray Guns

>> Defining Smart Control Systems

>> Core Components of Smart Control Systems

● How Smart Systems Optimize Spray Performance

>> Precise Control of Operating Parameters

>> Adaptive Performance Based on Environmental Conditions

>> Real-Time Monitoring and Feedback Loops

>> Predictive Maintenance and Diagnostics

● Benefits of Smart Control Integration

>> Improved Coating Quality

>> Increased Material Efficiency

>> Enhanced Productivity

>> Better Process Transparency

>> Easier Compliance With Standards

● Technological Innovations Driving Smart Control

>> Machine Learning Algorithms

>> Internet of Things (IoT) Connectivity

>> Advanced Sensors and Robotics

● Challenges and Considerations

>> Initial Investment Costs

>> System Complexity and Training

>> Integration with Existing Infrastructure

● Future Trends in Smart Electrostatic Spray Guns

● Frequently Asked Questions

Automatic electrostatic spray guns have revolutionized the coating industry by enhancing finish quality, reducing material waste, and increasing productivity. The integration of smart control systems into these devices has further improved their performance by enabling precise control, real-time monitoring, and adaptive functioning. This article explores how smart control systems optimize automatic electrostatic spray gun performance, discussing their key features, benefits, and technological principles.

Understanding Automatic Electrostatic Spray Guns

What Are Automatic Electrostatic Spray Guns?

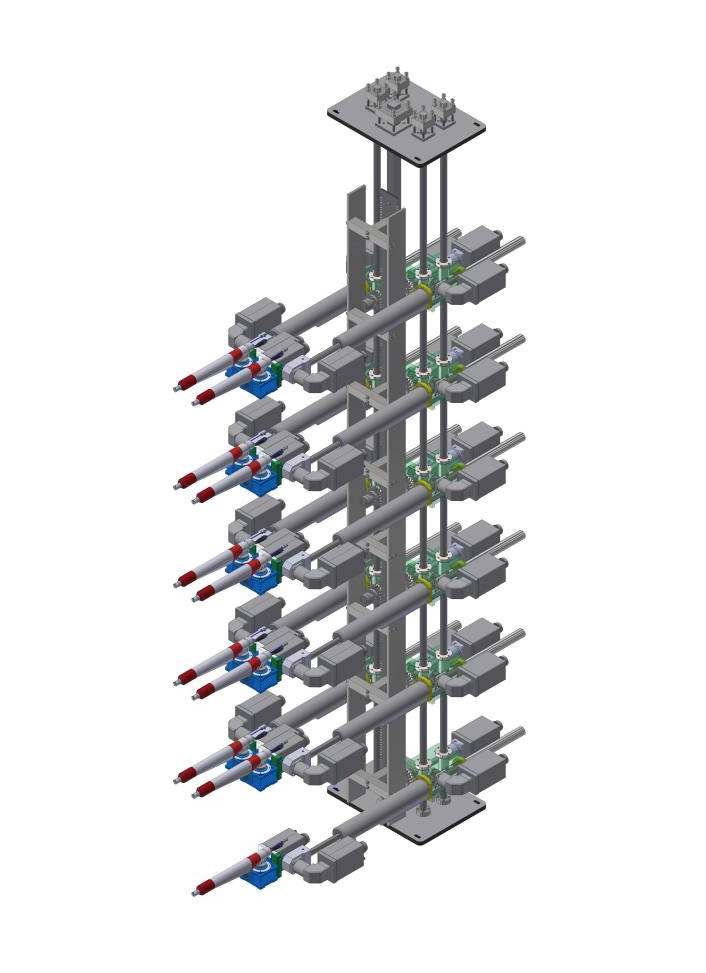

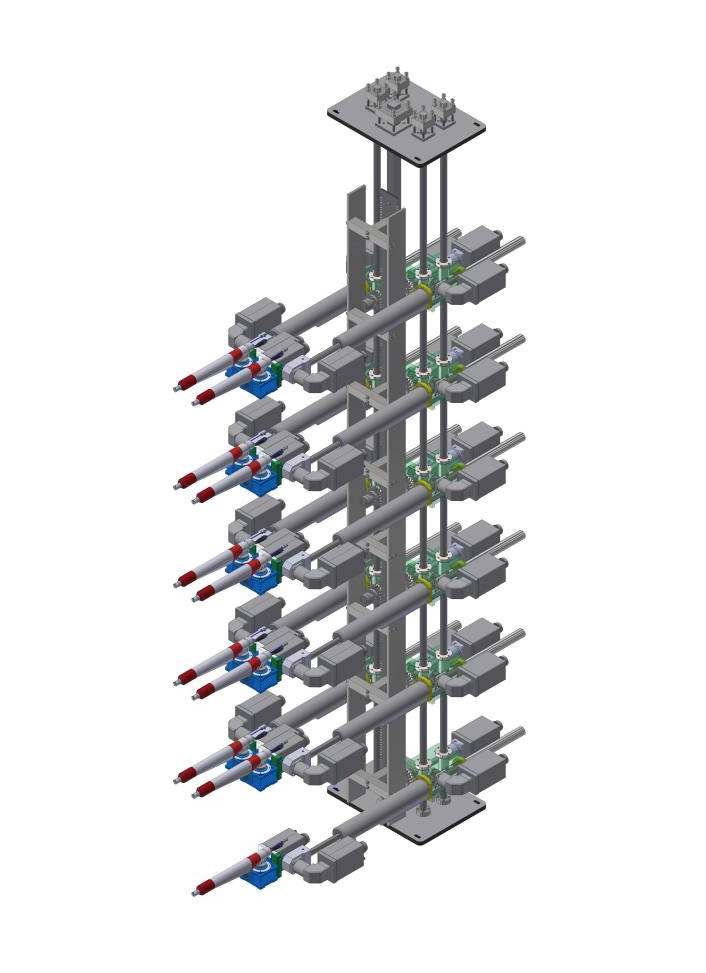

Automatic electrostatic spray guns are coating tools that use electrostatic forces to apply paint or other finishes onto surfaces efficiently and uniformly. They work by charging paint particles electrically as they exit the nozzle, causing them to be attracted to the grounded workpiece. This process results in better transfer efficiency, reduced overspray, and uniform film thickness.

Applications and Importance

These spray guns are widely used across automotive, aerospace, furniture, and industrial manufacturing sectors where high-quality finishes are essential. Compared to manual spraying methods, automatic electrostatic systems ensure repeatability and precision, enhancing product appearance and durability while lowering costs.

The Role of Smart Control Systems in Electrostatic Spray Guns

Defining Smart Control Systems

Smart control systems involve the integration of microprocessors, sensors, software algorithms, and connectivity features to automate and optimize the functioning of electrostatic spray guns. They facilitate intelligent decision-making by constantly analyzing operational parameters and environmental conditions.

Core Components of Smart Control Systems

- Sensors: Detect variables such as spray pressure, paint flow rate, electrostatic charge levels, and environmental factors like temperature and humidity.

- Microprocessor Controllers: Process sensor data to adjust the spray gun's operation continuously.

- User Interfaces: Provide operators with real-time data insights and control options via touchscreens or remote monitoring devices.

- Communication Modules: Enable connectivity with plant networks and cloud systems for data logging and remote diagnostics.

How Smart Systems Optimize Spray Performance

Precise Control of Operating Parameters

Through continuous sensor feedback, smart control systems precisely manage:

- Voltage and Current: Dynamically adjusting the electrostatic charge applied to paint particles to maximize deposition efficiency.

- Paint Flow: Regulating flow rates to maintain consistent spray patterns and film thickness.

- Air Pressure: Managing atomization for optimal droplet sizes and surface coverage.

This exacting control leads to consistent finish quality and minimal paint waste.

Adaptive Performance Based on Environmental Conditions

Environmental variables such as temperature, humidity, and airflow dramatically affect spray gun performance and finish quality. Smart systems compensate by adjusting parameters automatically to maintain optimal conditions.

For example, if humidity rises, the system may modify voltage or flow settings to prevent paint defects due to moisture interference.

Real-Time Monitoring and Feedback Loops

Smart control systems use closed-loop feedback mechanisms to monitor key metrics continuously. If deviations from target values occur, the system makes instantaneous corrections. This reduces errors, rework, and material consumption.

Predictive Maintenance and Diagnostics

By analyzing operational data trends, smart systems can alert users to potential equipment wear or malfunctions before they cause failures. This proactive maintenance approach minimizes downtime and extends spray gun lifespan.

Benefits of Smart Control Integration

Improved Coating Quality

The primary advantage is the enhanced quality of paint finishes, including uniform thickness, smooth texture, and consistent color, achieved through precise spraying control and adaptation to conditions.

Increased Material Efficiency

Reducing overspray and ensuring correct deposition maximize paint utilization, lowering production costs and minimizing environmental impact.

Enhanced Productivity

Automation of parameter adjustments and error correction speeds up manufacturing cycles and reduces the need for manual intervention.

Better Process Transparency

Operators gain full visibility into spray operations via dashboards and data analytics, enabling informed decisions and continuous improvement.

Easier Compliance With Standards

Smart systems facilitate adherence to regulatory requirements concerning VOC emissions, paint usage, and safety by documenting processes and adjusting usage accordingly.

Technological Innovations Driving Smart Control

Machine Learning Algorithms

Implementing machine learning allows spray guns to refine their performance based on historical data and evolving operational contexts, improving efficiency over time.

Internet of Things (IoT) Connectivity

IoT integration enables remote monitoring, control, and integration with factory-wide management systems for coordinated operations and data-driven insights.

Advanced Sensors and Robotics

High-precision sensors combined with robotic arms enhance accuracy and consistency, enabling complex coating patterns and difficult geometries to be sprayed flawlessly.

Challenges and Considerations

Initial Investment Costs

Implementing smart control systems involves upfront costs for advanced hardware and software, which may be significant for small manufacturers.

System Complexity and Training

Operators and maintenance teams require training to utilize smart systems effectively and interpret the data generated.

Integration with Existing Infrastructure

Retrofitting older spray booths or production lines can face compatibility challenges.

Future Trends in Smart Electrostatic Spray Guns

- Increased AI-driven automation for greater autonomy.

- Enhanced multi-material spraying capabilities.

- Integration with augmented reality (AR) for operator training and diagnostics.

- Greater emphasis on sustainability through optimized resource use.

Frequently Asked Questions

Q1: How do smart control systems improve paint transfer efficiency?

Smart controls adjust electrostatic charge and spray parameters in real-time based on sensor data, maximizing the attraction of paint particles to the workpiece and minimizing overspray.

Q2: Can smart control systems adapt to different coating materials?

Yes, many systems have presets or learning capabilities to adjust settings for various paint viscosities, formulations, and colors, ensuring optimal performance.

Q3: What kind of maintenance does a smart electrostatic spray gun require?

Aside from standard cleaning, smart systems often include predictive maintenance alerts for components like nozzles and sensors, helping schedule timely servicing.

Q4: Are smart electrostatic spray guns compatible with existing robotic paint lines?

Yes, most are designed for easy integration with robotic arms and automation systems, enhancing overall coating process control.

Q5: What environmental benefits do smart-controlled spray guns offer?

By reducing paint waste and emissions, optimizing usage, and enabling compliance documentation, smart systems contribute to greener manufacturing practices.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.