Content Menu

● Introduction

● Understanding the Technologies

>> What is an Automatic Electrostatic Spray Gun?

>>> Key Components and Operation

>> What Is a Liquid Coating System?

>>> Key Components and Operation

● In-Depth Comparison

>> Application Efficiency

>>> Electrostatic Spray Guns

>>> Liquid Coating Systems

>> Coating Consistency and Quality

>>> Electrostatic Spray Guns

>>> Liquid Coating Systems

>> Cost-Effectiveness

>>> Electrostatic Spray Guns

>>> Liquid Coating Systems

>> Environmental Considerations

>>> Electrostatic Spray Guns

>>> Liquid Coating Systems

>> Versatility and Material Compatibility

>>> Electrostatic Spray Guns

>>> Liquid Coating Systems

● Detailed Pros and Cons

>> Automatic Electrostatic Spray Gun

>>> Pros

>>> Cons

>> Liquid Coating Systems

>>> Pros

>>> Cons

● Real-World Application Scenarios

>> When to Choose Electrostatic Spray Guns

>> When to Choose Liquid Coating Systems

● Maintenance and Operational Considerations

>> Electrostatic Spray Guns

>> Liquid Coating Systems

● Future Trends in Coating Technologies

● Frequently Asked Questions

>> 1. Can electrostatic spray guns be used on plastic or wood surfaces?

>> 2. What are the key safety concerns with electrostatic spray guns?

>> 3. Which system is better for quick color changes?

>> 4. How do environmental regulations affect system choice?

>> 5. Are robotic applicators compatible with both systems?

Introduction

The world of industrial painting and surface finishing has witnessed significant advancements in recent years. Two methods stand out for their effectiveness and widespread adoption: automatic electrostatic spray guns and traditional liquid coating systems. Companies and professionals continually seek the most efficient, cost-effective, and high-quality methods to meet their production and aesthetic goals. This article delves deeply into the comparison between automatic electrostatic spray guns and conventional liquid coating systems, examining their respective mechanisms, benefits, disadvantages, and best-use scenarios.

Understanding the Technologies

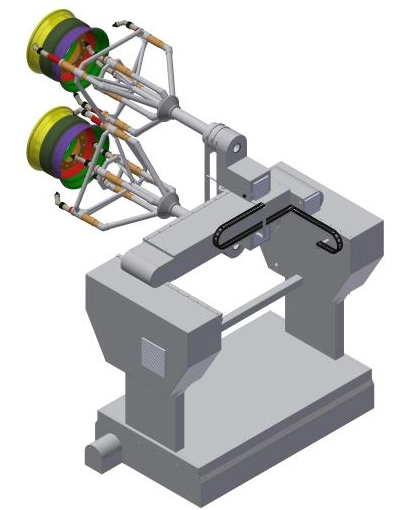

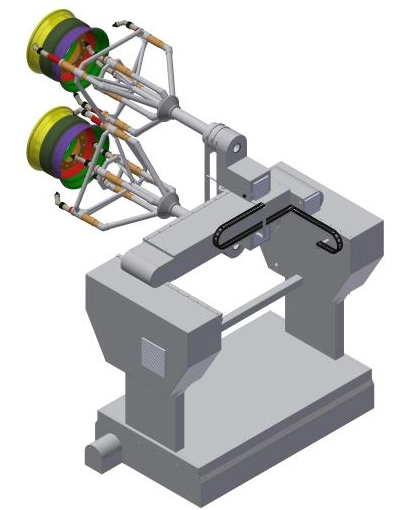

What is an Automatic Electrostatic Spray Gun?

An automatic electrostatic spray gun is a technologically advanced painting tool that leverages electrostatic principles to apply coatings to a wide range of surfaces. The core concept involves charging paint particles and then spraying them towards electrically grounded workpieces. Opposite electrical charges attract, so the charged paint is drawn powerfully to the object's surface, resulting in superior adhesion and coverage.

Key Components and Operation

- Power Supply Unit – Generates the high voltage required to charge paint particles.

- Gun Head and Nozzle – Dispenses and atomizes the coating material.

- Control Console – Allows customization of spray patterns, flow rates, and voltage.

- Grounding Equipment – Ensures the workpiece has an opposing charge for maximized attraction.

What Is a Liquid Coating System?

A liquid coating system involves the manual or automatic application of liquid paints, varnishes, or finishes onto surfaces. This system is the traditional choice for painting and protective coatings in many industries.

Key Components and Operation

- Spray Guns or Nozzles – Can be manual or automated, used to apply coatings.

- Paint Reservoirs – Hold the liquid materials.

- Compressed Air or Pumps – Deliver the coating through the gun under pressure.

- Curing/Drying Equipment – Facilitates the drying process for specific coating types.

In-Depth Comparison

Application Efficiency

Electrostatic Spray Guns

- Higher Transfer Efficiency: Electrostatic spray guns boast transfer efficiencies as high as 90%, as most of the atomized particles are drawn to the target surface. This minimizes overspray and waste.

- Coverage on Complex Shapes: Thanks to the “wrap-around effect,” charged particles naturally coat both exposed and hidden surfaces.

Liquid Coating Systems

- Lower Transfer Efficiency: Standard liquid coating processes using conventional spray guns typically achieve 40-60% transfer efficiency.

- Manual Dexterity Needed: Achieving uniform coverage, especially on complex geometries, demands skill or specialized automated setups.

Coating Consistency and Quality

Electrostatic Spray Guns

- Uniform Layer Thickness: The electrical attraction fosters a consistent paint distribution, reducing runs, sags, and film irregularities.

- Smoother Finishes: This method often results in smoother, high-quality finishes with more uniform gloss and color.

Liquid Coating Systems

- Potential for Variability: The quality is more operator-dependent or reliant on the exact calibration of automated systems.

- Greater Film Build Variation: There is often a higher risk of uneven film thickness, especially when recoating or painting surfaces with complex profiles.

Cost-Effectiveness

Electrostatic Spray Guns

- Paint Savings: Superior transfer efficiency reduces paint consumption and waste, resulting in notable cost savings.

- Equipment Investment: Initial setup costs are higher due to the need for high-voltage power supplies and specialized guns.

- Maintenance Needs: While not extensive, electrostatic systems do require specific maintenance to ensure safe operation.

Liquid Coating Systems

- Lower Entry Cost: Traditional liquid systems are more affordable up-front, making them attractive for smaller operations or start-ups.

- Higher Ongoing Consumption: Less efficient paint transfer and more frequent overspray lead to higher ongoing material costs.

- Simpler Maintenance: With fewer complex components, maintenance may be easier and less specialized.

Environmental Considerations

Electrostatic Spray Guns

- Reduced Overspray and Emissions: The efficient particle attraction means less paint is lost to the environment, resulting in reduced volatile organic compound (VOC) emissions and a cleaner workspace.

- Safer Air Quality: There's less airborne particulate matter, improving workplace safety and environmental compliance.

Liquid Coating Systems

- More Overspray: Conventional methods generally see more wasted paint and higher VOC emissions.

- Potential Environmental Burden: Higher emissions can increase environmental impact and make regulatory compliance more challenging.

Versatility and Material Compatibility

Electrostatic Spray Guns

- Best for Conductive Materials: To function optimally, electrostatic guns require workpieces to be electrically conductive or suitably grounded. They are ideal for metals but less effective on wood, plastics, or insulated surfaces unless pre-treated.

- Limited by Certain Paint Types: Some paints, especially those with high viscosity or certain pigments, may not atomize well in electrostatic systems.

Liquid Coating Systems

- Wider Material Compatibility: Conventional liquid spraying can be effectively used on metals, plastics, wood, and composites without significant modification.

- Flexible with Paint Types: Can handle a broader range of viscosities and formulation additives.

Detailed Pros and Cons

Automatic Electrostatic Spray Gun

Pros

- Highly efficient paint transfer, minimizing waste.

- Superior wrap-around effect for complex geometries.

- Consistent, uniform finishes with fewer defects.

- Reduced operating costs over the long term due to savings on paint and cleanup.

- Safer work environment with less airborne overspray.

Cons

- Higher initial equipment investment.

- Workpieces must be conductive or properly grounded.

- Not suitable for all paint types or non-conductive materials without special treatment.

- More complex setup and training required.

- Maintenance involves handling high-voltage components.

Liquid Coating Systems

Pros

- Lower upfront costs for equipment and setup.

- Applicable to virtually any substrate, including non-conductive materials.

- Effective with a wide range of paint types, viscosities, and finishes.

- Easy to use and maintain, especially for small to medium batches.

- Minimal specialized training required for basic operation.

Cons

- Less efficient, resulting in more waste and higher materials consumption.

- Greater potential for inconsistent quality on complex parts or with inexperienced operators.

- Higher emissions and potential environmental impact.

- Increased cleanup requirements due to overspray and spillage.

Real-World Application Scenarios

When to Choose Electrostatic Spray Guns

- When coating large volumes of metal parts with intricate shapes.

- Where achieving premium finish quality and minimal waste is paramount.

- In operations with stringent environmental regulations aiming for low VOC emissions.

When to Choose Liquid Coating Systems

- For coatings on non-conductive materials or substrates.

- In operations where initial capital is limited and batch sizes are small.

- Where a wide variety of coatings and color changes are required.

Maintenance and Operational Considerations

Electrostatic Spray Guns

- Routine Inspection: Ongoing checks of high-voltage systems and regular cleaning of nozzles.

- Operator Training: Personnel must be well-trained in handling electrical components and safety protocols.

- Grounding and Safety: Ensuring proper grounding is critical to avoid hazards and maintain efficiency.

Liquid Coating Systems

- Basic Cleaning: Frequent cleaning of guns, nozzles, and reservoirs.

- Less Intensive Training: Operators can be trained quickly for basic applications.

- Less Complex Repairs: Standard parts are readily available and maintenance is straightforward.

Future Trends in Coating Technologies

Advances in materials science and automation are influencing developments in both electrostatic and liquid coating technologies. Emerging trends include:

- Development of conductive primers and pre-treatments for non-metal substrates, expanding electrostatic application possibilities.

- Smarter automation and digital controls for both systems, improving consistency, traceability, and process optimization.

- Environmental innovations aimed at reducing VOC emissions and waste, often driven by stricter environmental legislation.

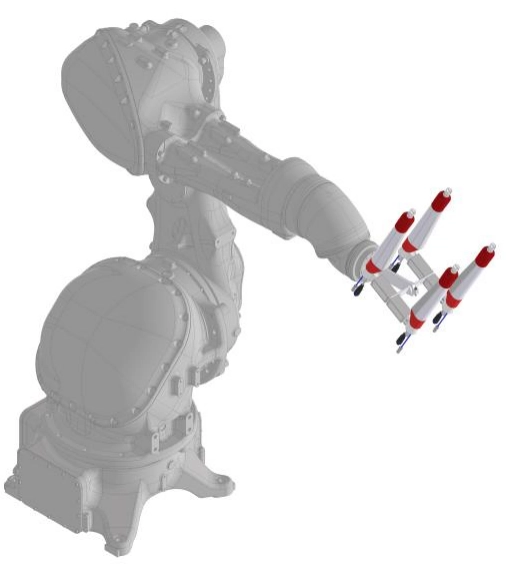

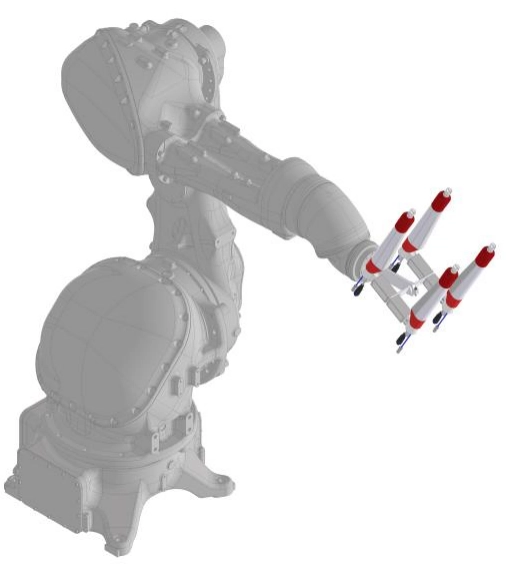

- Integration with robotic arms and conveyors for increased throughput and reduced human error.

Frequently Asked Questions

1. Can electrostatic spray guns be used on plastic or wood surfaces?

Electrostatic spray guns are most effective with conductive materials. However, there are workarounds, such as applying conductive primers or treating surfaces to enhance conductivity. Still, these workarounds can add cost and complexity, and results may vary depending on the substrate.

2. What are the key safety concerns with electrostatic spray guns?

The main safety concern centers around high-voltage operation. Proper grounding of both equipment and workpieces is critical to preventing accidental discharge. Operators should be trained in handling high-voltage equipment and in emergency procedures.

3. Which system is better for quick color changes?

Traditional liquid coating systems are generally better suited for quick color changes, as they have simpler paint flow setups and are easier to clean between jobs. Electrostatic systems often require more involved cleaning to avoid cross-contamination.

4. How do environmental regulations affect system choice?

Electrostatic spray systems produce lower VOC emissions due to high transfer efficiency and less overspray, making them easier to bring into compliance with strict environmental standards. Conventional liquid coating may require additional investments, such as recovery systems or air purification setups, to meet the same standards.

5. Are robotic applicators compatible with both systems?

Yes, both electrostatic and liquid coating systems can be integrated with robotic applicators, enhancing consistency and throughput. However, electrostatic systems may require additional safety and grounding measures within the automation setup.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.