Content Menu

● Understanding Electrostatic Spray Gun Technology

>> How Electrostatic Spray Guns Work

● Manual Electrostatic Spray Guns

>> What Are Manual Electrostatic Spray Guns?

>> Advantages of Manual Electrostatic Spray Guns

>> Disadvantages of Manual Electrostatic Spray Guns

● Automatic Electrostatic Spray Guns

>> What Are Automatic Electrostatic Spray Guns?

>> Advantages of Automatic Electrostatic Spray Guns

>> Disadvantages of Automatic Electrostatic Spray Guns

● Key Factors to Consider When Choosing Between Manual and Automatic Electrostatic Spray Guns

>> Production Volume and Speed

>> Part Size, Shape, and Complexity

>> Cost and Return on Investment (ROI)

>> Quality and Consistency Demands

>> Environmental and Safety Considerations

● Overcoming Challenges in Electrostatic Coating

>> Addressing the Faraday Cage Effect

>> Maintenance and Operational Considerations

● Case Studies: Applications of Manual vs Automatic Electrostatic Spray Guns

>> Manual Electrostatic Spray Gun Use Cases

>> Automatic Electrostatic Spray Gun Use Cases

● Frequently Asked Questions (FAQs)

>> 1. Can manual and automatic electrostatic spray guns be used together in the same coating line?

>> 2. How much paint savings can electrostatic spray guns provide?

>> 3. Are electrostatic spray guns suitable for non-metal surfaces?

>> 4. What maintenance is essential for electrostatic spray guns?

>> 5. How does voltage adjustment impact coating quality in electrostatic spray guns?

In modern coating applications, electrostatic spray guns have become essential tools to achieve high-quality finishes with improved efficiency. Choosing between manual and automatic electrostatic spray guns can significantly impact the productivity, finish quality, and cost-effectiveness of your coating line. This article explores the differences, advantages, and considerations of manual versus automatic electrostatic spray guns to help you decide which option best fits your specific coating requirements.

Understanding Electrostatic Spray Gun Technology

Electrostatic spray guns use the principle of electrostatics to charge paint or coating particles as they are atomized and sprayed toward a grounded workpiece. The negatively charged particles are attracted to the grounded surface, resulting in efficient transfer, minimal overspray, and a uniform coating. This technology enhances paint savings, reduces volatile organic compounds (VOCs), and often shortens production cycles.

How Electrostatic Spray Guns Work

An electrostatic spray gun applies an electric charge—either directly on the paint at the nozzle or indirectly through an electrostatic field—to atomized paint particles. When sprayed onto a grounded metal surface or substrate, the charged particles wrap around the object, including recessed and complex shapes, maximizing coverage with minimal waste.

Manual Electrostatic Spray Guns

What Are Manual Electrostatic Spray Guns?

Manual electrostatic spray guns are handheld devices operated by skilled workers who control the spray pattern, distance, and speed in real time. They often serve in applications demanding flexibility, precision, or smaller production runs.

Advantages of Manual Electrostatic Spray Guns

- Precision and Control: Operators can adjust spray angles, distance, and speed on the fly, allowing for detailed and customized coating applications.

- Lower Initial Investment: Manual units generally cost less upfront compared to automatic robotic systems.

- Flexibility: Ideal for varied product sizes, shapes, or low-to-medium volume runs where automation may be cost-prohibitive or impractical.

- Reduced Paint Waste: The electrostatic charge improves transfer efficiency—manual electrostatic guns can reduce paint consumption by up to 40% compared to conventional spray guns.

- Ease of Use for Complex Parts: The operator can reach difficult surfaces or small-scale parts where automated systems might struggle.

Disadvantages of Manual Electrostatic Spray Guns

- Operator Dependency: Quality and consistency depend heavily on the operator's skill and experience.

- Lower Throughput: Manual spraying is generally slower than automated systems, affecting cycle times in high-volume lines.

- Fatigue and Ergonomics: Continuous manual spraying can cause fatigue and reduce precision over time.

- Limited Repeatability: Variations between operators or across shifts can affect coating uniformity.

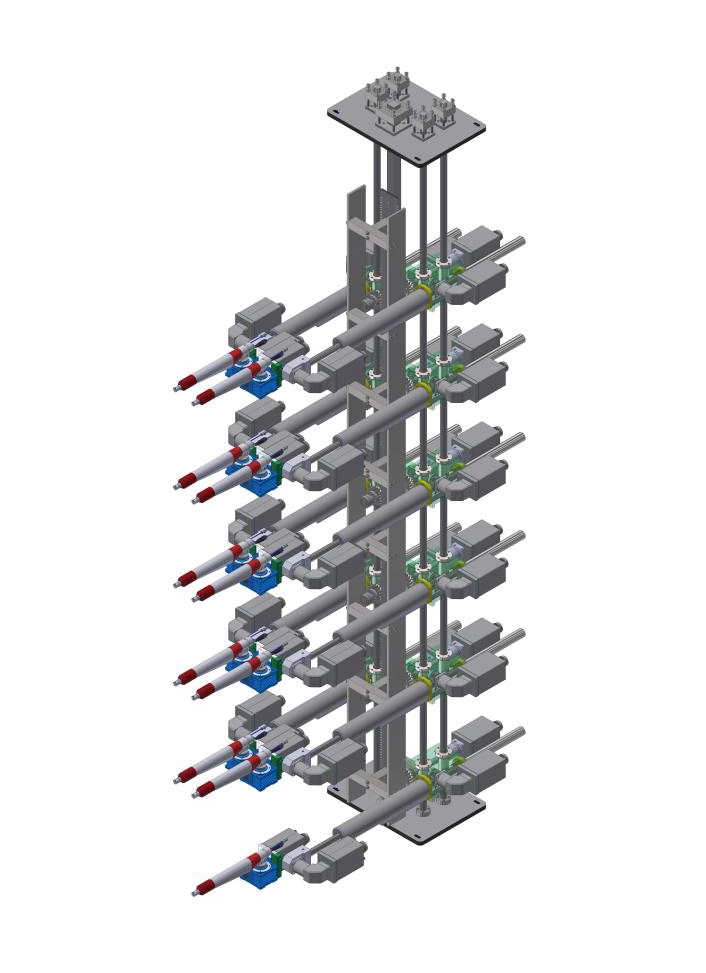

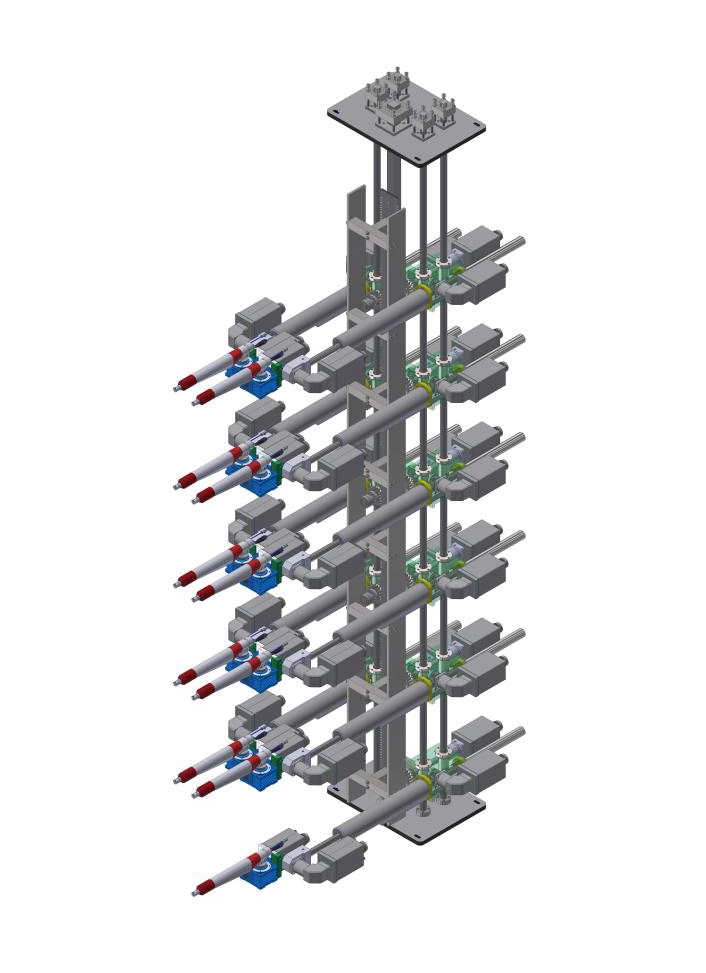

Automatic Electrostatic Spray Guns

What Are Automatic Electrostatic Spray Guns?

Automatic electrostatic spray guns are integrated into robotic or conveyorized coating lines. The spray parameters, movements, and voltages are controlled by computer systems that ensure consistent application over large production volumes.

Advantages of Automatic Electrostatic Spray Guns

- Consistent Quality and Repeatability: Automation eliminates operator variability, ensuring uniform coating thickness and finish across all parts.

- High Throughput: Automated systems can operate continuously and at faster speeds, meeting the demands of mass production efficiently.

- Reduced Labor Costs: Automation reduces the need for skilled operators to handle spraying tasks, optimizing labor resources.

- Integration with Production Lines: Automatic spray guns easily integrate with conveyor systems, robots, and programmable controllers for seamless operation.

- Advanced Features: Many automatic guns automatically adjust voltage based on material flow and surface characteristics, optimizing transfer efficiency and finish.

Disadvantages of Automatic Electrostatic Spray Guns

- Higher Initial Costs: Automation systems require significant capital investment, including robotics, control systems, and integration.

- Less Flexibility: Fixed programming can make it harder to handle custom or highly varied parts without reprogramming.

- Maintenance Complexity: Automated systems are mechanically complex and may require specialized maintenance personnel.

- Setup Time: Initial programming and calibration require more time and expertise before production can start.

Key Factors to Consider When Choosing Between Manual and Automatic Electrostatic Spray Guns

Production Volume and Speed

- Choose manual electrostatic guns for low to medium volume or batch production where flexibility is important.

- Opt for automatic systems when high volume, continuous production, or short cycle times are business priorities.

Part Size, Shape, and Complexity

- Manual guns excel at small parts, intricate shapes, or when precise, localized coating control is needed.

- Automatic guns shine in coating uniform, regularly shaped parts and items produced in large uniform batches.

Cost and Return on Investment (ROI)

- Initial costs for manual electrostatic guns are lower, but labor costs are higher.

- Automated systems have higher upfront investment but reduce labor dependency and paint waste, often achieving a fast ROI through material savings and throughput gains.

Quality and Consistency Demands

- For products requiring consistent finish quality with minimal variability, automated guns provide the best outcome.

- When operator skill is guaranteed and customization is necessary, manual guns provide more adaptability.

Environmental and Safety Considerations

- Both manual and automatic electrostatic guns reduce overspray and VOC emissions compared to conventional spray guns.

- Automation reduces human exposure to paint fumes and chemicals, improving workplace safety.

Overcoming Challenges in Electrostatic Coating

Addressing the Faraday Cage Effect

The Faraday cage effect can cause reduced coating in recessed or shadowed areas when using electrostatics. Solutions include combining manual with electrostatic spraying or adjusting electrostatic parameters like voltage and air pressure to direct paint flow effectively.

Maintenance and Operational Considerations

Regular cleaning and inspection are critical to maintaining spray gun performance. For automated systems, preventive maintenance programs ensure uptime and consistent quality. Both types require proper grounding and safety protocols to prevent electrical hazards.

Case Studies: Applications of Manual vs Automatic Electrostatic Spray Guns

Manual Electrostatic Spray Gun Use Cases

- Custom automotive restoration where detail painting is crucial.

- Aerospace parts with diverse shapes needing varied coating approaches.

- Maintenance painting or small-batch productions with frequent job changes.

Automatic Electrostatic Spray Gun Use Cases

- Large-scale manufacturing such as appliance or metal furniture production.

- OEM coating lines needing high throughput with minimal variability.

- Industrial products requiring consistent corrosion resistance coatings in mass quantities.

Frequently Asked Questions (FAQs)

1. Can manual and automatic electrostatic spray guns be used together in the same coating line?

Yes, some facilities use a hybrid approach, employing manual guns for detailed or hard-to-reach areas and automatic guns for general coverage to optimize efficiency and quality.

2. How much paint savings can electrostatic spray guns provide?

Electrostatic spray guns can reduce paint consumption by up to 40% compared with conventional spray guns due to higher transfer efficiency and less overspray.

3. Are electrostatic spray guns suitable for non-metal surfaces?

Electrostatics work best with conductive surfaces like metals. For non-conductive surfaces such as plastics, conductive primers or specific electrostatic methods may be required to ensure coating adhesion.

4. What maintenance is essential for electrostatic spray guns?

Regular cleaning of nozzles and parts prevents blockages. Inspect and replace worn seals and components. Proper grounding and safe handling of electrical parts are critical to safety and performance.

5. How does voltage adjustment impact coating quality in electrostatic spray guns?

Voltage controls the strength of the electrostatic charge. Adjusting voltage helps balance paint attraction, minimizing overspray and improving wrap-around coverage, especially important in automatic systems with dynamic surfaces.

[1] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/conventional-vs-electrostatic-spray-guns.html

[2] https://www.alibaba.com/showroom/electrostatic-liquid-painting-equipment.html

[3] https://www.youtube.com/watch?v=h3zbxTAFKtY

[4] https://www.durr.com/cn/media/news/news-detail/view/less-paint-consumption-new-electrostatic-spray-gun-for-a-more-efficient-painting-process-89612

[5] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/advantages-of-spraying-with-electrostatic-guns.html

[6] https://www.alibaba.com/showroom/electrostatic-spray-gun-coating-machine.html

[7] https://www.wagner-group.com/en/industry/products/liquid-coating/electrostatic-liquid-coating/

[8] https://patents.google.com/patent/CN100360246C/zh

[9] https://patvin.co.in/blog/manual-vs-automatic-spray-guns/

[10] https://patents.google.com/patent/CN101014415A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.