Content Menu

● What is Electrostatic Powder Coating?

● Why Choose Automatic Electrostatic Spray Guns?

● Top Automatic Electrostatic Spray Guns in 2025

>> Encore® Automatic Powder Coating Guns by Nordson

>> GM 5000EA Automatic Gun by Wagner Group

>> OptiGun® Automatic Enamel Gun by Gema Switzerland

>> AH-S500 Manual and Automatic Electrostatic Powder Coating Gun by Dezhou Aohai Coating Equipment

>> Ransburg Electrostatic Powder Coating Guns by Binks

● Key Features to Look for in Automatic Electrostatic Spray Guns

>> Electrostatic Charge and Transfer Efficiency

>> Cleaning and Maintenance

>> Ergonomics and Mounting Flexibility

>> Safety Features

>> Material Compatibility

● Advantages of Using Automatic Electrostatic Spray Guns in 2025

● Challenges and Solutions in Electrostatic Powder Coating

>> Faraday Cage Effect

>> Color Change Downtime

>> Powder Waste

● Future Trends in Automatic Electrostatic Spray Guns

● Frequently Asked Questions (FAQs)

Industrial powder coating has become a cornerstone technology in manufacturing, offering durable, high-quality finishes with excellent environmental benefits. In 2025, automatic electrostatic spray guns represent the pinnacle of efficiency, precision, and reliability in powder coating applications. This article explores the best automatic electrostatic spray guns available for industrial powder coating in 2025, highlighting their features, benefits, and technological advancements that make them indispensable for modern manufacturing.

What is Electrostatic Powder Coating?

Electrostatic powder coating is a process where finely ground powder particles are electrically charged and sprayed onto a grounded workpiece. The charged powder adheres uniformly to the surface, and after application, the coated item is cured under heat to form a hard, durable finish. This method is widely used for its superior transfer efficiency, minimal waste, and environmentally friendly nature compared to traditional liquid painting.

Why Choose Automatic Electrostatic Spray Guns?

Automatic guns offer several advantages over manual systems:

- Consistent coating quality with precise control of powder flow and electrostatic charge.

- Higher transfer efficiency, reducing powder waste and operational costs.

- Faster color changes and reduced downtime.

- Integration with robotic systems for high-volume production.

- Improved operator safety with automated grounding and voltage control.

Top Automatic Electrostatic Spray Guns in 2025

Encore® Automatic Powder Coating Guns by Nordson

Nordson's Encore® series is renowned for its reliability and advanced technology. These guns produce up to 100 kV of electrostatic charge, delivering the highest transfer efficiency in venturi-based coating systems. Key features include:

- Select Charge® technology for superior coating coverage.

- Automatic Feedback Current (AFC) control for consistent transfer efficiency.

- Air-purge cleanable design enabling quick cleaning without disassembly.

- Adjustable mounting brackets allow flexible positioning to coat complex parts.

- Special materials in powder-contact parts reduce wear and impact fusion.

- Optional ion collectors to improve finish quality by drawing excess ions away.

The Encore® guns are available in various configurations, including tube and bar mounts, and are suitable for porcelain enamel applications. Their lightweight and compact design enhances operator comfort and efficiency in industrial environments.

GM 5000EA Automatic Gun by Wagner Group

The GM 5000EA is designed for soft, homogeneous spray jets that ensure high coating quality and application efficiency. Highlights include:

- Robust construction suitable for harsh environments.

- High operating comfort and ergonomic design.

- Compliance with CE and ATEX Zone 1 standards for safety.

- Grounding monitoring with automatic high-voltage shutoff to protect operators.

- Exchangeable hooks to reduce service costs.

- Typically saves 30-50% of coating material compared to conventional methods.

This gun is ideal for users seeking a balance between durability, safety, and efficiency in electrostatic powder coating.

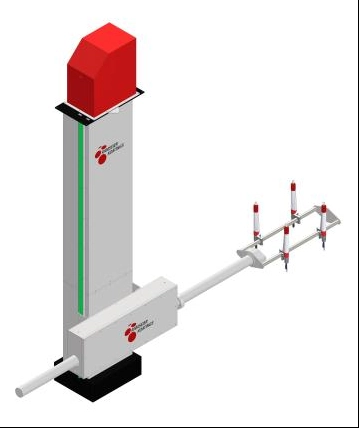

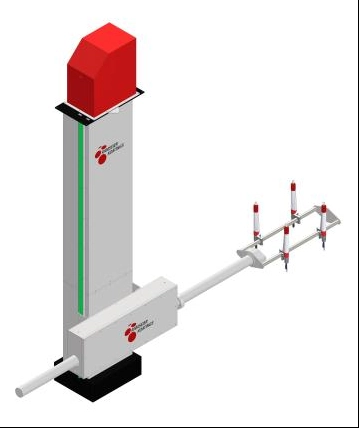

OptiGun® Automatic Enamel Gun by Gema Switzerland

Gema's OptiGun® stands out for its robustness and efficiency, especially in enamel powder applications. Features include:

- Industry-leading PowerBoost® technology for enhanced coating results.

- Flexible mounting options for robot integration, including nozzle extensions for hard-to-reach areas.

- Excellent ergonomics and lightweight design for fatigue-free manual operation.

- Wide range of nozzles for optimal spray patterns tailored to different powders and objects.

- Use of triboelectric charging technology in both manual and automatic versions.

The OptiGun® is engineered to handle complex coating requirements and is a preferred choice for automated industrial coating lines.

AH-S500 Manual and Automatic Electrostatic Powder Coating Gun by Dezhou Aohai Coating Equipment

Dezhou Aohai offers advanced technology with the AH-S500, which incorporates:

- Built-in electrostatic injection molding technology compatible with imported machines.

- Precision charging control with adjustable current down to 10 μA.

- Ultra-high efficiency powder pump for uniform powder transmission and reduced waste.

- Intelligent internal protection that automatically adjusts voltage and current based on the workpiece shape.

- Spray memory storage to avoid repetitive adjustments and ensure consistent coverage.

- Ergonomic design for comfortable manual operation and precise application.

This equipment is suitable for industries requiring high precision and adaptability in powder coating.

Ransburg Electrostatic Powder Coating Guns by Binks

Ransburg, a brand under Binks, offers a comprehensive range of electrostatic powder coating solutions designed to:

- Boost productivity and reduce operational costs.

- Provide excellent coverage even in deep recesses and complex geometries.

- Minimize powder waste with transfer efficiencies that reduce overspray.

- Support fast color changes and streamlined application processes.

- Operate with minimal emissions, improving workplace air quality.

Their systems are engineered for industrial durability and ease of use, making them a top choice for large-scale manufacturing facilities.

Key Features to Look for in Automatic Electrostatic Spray Guns

When selecting an automatic electrostatic spray gun for industrial powder coating, consider the following:

Electrostatic Charge and Transfer Efficiency

High voltage output (up to 100 kV) and technologies like Automatic Feedback Current (AFC) improve powder adhesion and reduce waste.

Cleaning and Maintenance

Air-purge cleanable designs and easy disassembly reduce downtime during color changes and routine maintenance.

Ergonomics and Mounting Flexibility

Lightweight guns with adjustable mounting brackets or robot-compatible mounts enhance ease of use and coating precision.

Safety Features

Grounding monitoring and automatic shutoff systems protect operators and ensure compliance with safety standards.

Material Compatibility

Guns should handle a variety of powders, including enamel and specialty coatings, with minimal wear on powder-contact parts.

Advantages of Using Automatic Electrostatic Spray Guns in 2025

- Improved Coating Quality: Uniform coverage with minimal defects.

- Cost Efficiency: Reduced powder consumption and labor costs.

- Environmental Benefits: Low VOC emissions and powder reclaimability.

- Operational Flexibility: Quick color changes and adaptability to complex parts.

- Enhanced Safety: Automated controls and grounding monitoring.

Challenges and Solutions in Electrostatic Powder Coating

Faraday Cage Effect

Automatic guns with superior Faraday-cage penetration capabilities can coat recessed and complex geometries more effectively.

Color Change Downtime

Air-purge cleaning and memory storage features minimize downtime during frequent color changes.

Powder Waste

High transfer efficiency and powder recovery systems reduce overspray and waste significantly.

Future Trends in Automatic Electrostatic Spray Guns

- Integration with AI and machine learning for process optimization.

- Enhanced sensor technology for real-time monitoring of coating parameters.

- Development of more compact, lightweight guns for improved ergonomics.

- Advanced materials to further reduce wear and maintenance needs.

- Increased automation for seamless integration with Industry 4.0 manufacturing lines.

Frequently Asked Questions (FAQs)

Q1: What is the maximum voltage output of the best automatic electrostatic spray guns?

A1: Top models like Nordson's Encore® can produce up to 100 kV, ensuring high transfer efficiency and superior coating quality.

Q2: How do automatic electrostatic spray guns improve powder usage efficiency?

A2: They use precise electrostatic charging and optimized powder flow control, reducing overspray and enabling powder reclaim rates up to 97%.

Q3: Can automatic electrostatic spray guns be used with robotic coating systems?

A3: Yes, many guns, such as Gema's RobotGun and OptiGun®, are designed for easy integration with robots, allowing automated high-volume coating.

Q4: What safety features are included in modern automatic electrostatic spray guns?

A4: Features include grounding monitoring, automatic high-voltage shutoff, and compliance with safety standards like CE and ATEX Zone 1.

Q5: How do automatic spray guns handle complex part geometries?

A5: They incorporate technologies to overcome Faraday cage effects and use adjustable mounts and nozzle extensions to coat hard-to-reach areas evenly.

[1] https://www.nordson.com/en/products/industrial-coating-systems-products/automatic-powder-coating-guns

[2] https://www.alibaba.com/product-detail/Hot-sale-model-manual-electrostatic-powder_1601431875932.html

[3] https://www.wagner-group.com/en/industry/products/liquid-coating/product/gm-5000ea/

[4] https://www.gemapowdercoating.com/en/products/powder-guns

[5] https://aohaicoasting.en.made-in-china.com/product/QEoRxqJdaBYw/China-Factory-Price-2025-Manual-Operation-Electrostatic-Powder-Coating-Spray-Gun-for-New-Starter-Test.html

[6] https://www.finishingconsultants.com/electrostatic-painting.php

[7] https://binks.com/powder-coating-equipment/

[8] https://www.alibaba.com/product-detail/2025-Easy-Operation-Automatic-Electrostatic-Powder_1601454775704.html

[9] https://us.metoree.com/categories/3942/

[10] https://www.wagner-group.com/us/industry/products/powder-coating/applying/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.