Content Menu

● Understanding Automatic Electrostatic Spray Guns

>> How Automatic Electrostatic Spray Guns Work

>> Advantages in Production Lines

● Planning for Integration

>> Assessing Current Production Line Compatibility

>> Defining Clearly the Coating Requirements

>> Evaluating Infrastructure Needs

● Equipment Selection and Configuration

>> Selecting Suitable Electrostatic Guns

>> Integration with Automation Systems

>> Positioning and Mounting

● Installation Best Practices

>> Grounding and Electrical Safety

>> Environmental Controls

>> Calibration and Initial Setup

● Operator Training and Maintenance

>> Comprehensive Operator Training

>> Scheduled Maintenance and Cleaning

>> Monitoring and Troubleshooting Tools

● Process Optimization and Quality Control

>> Integrating Feedback Systems

>> Conducting Routine Quality Checks

>> Continuous Improvement Strategies

● Case Studies of Successful Integration

>> Automotive Component Manufacturing

>> Furniture Production Line

● Challenges and Solutions

>> Managing Complex Part Geometries

>> Ensuring Worker Safety

>> Minimizing Downtime

● Future Trends in Electrostatic Spray Technology

>> Smart Spray Systems

>> Eco-Friendly Coatings and Equipment

>> Enhanced Automation and Integration

● FAQ about Automatic Electrostatic Spray Gun Integration

In modern manufacturing, achieving high-quality finishes efficiently is a priority. Automatic electrostatic spray guns have become indispensable tools in many production lines, offering precise coating application with reduced waste and enhanced surface coverage. Integrating these advanced spray guns effectively requires adherence to best practices to maximize their benefits and maintain smooth production flow. This article explores comprehensive strategies and techniques to successfully incorporate automatic electrostatic spray guns into production environments.

Understanding Automatic Electrostatic Spray Guns

Before discussing integration strategies, it is essential to grasp how automatic electrostatic spray guns operate and their advantages.

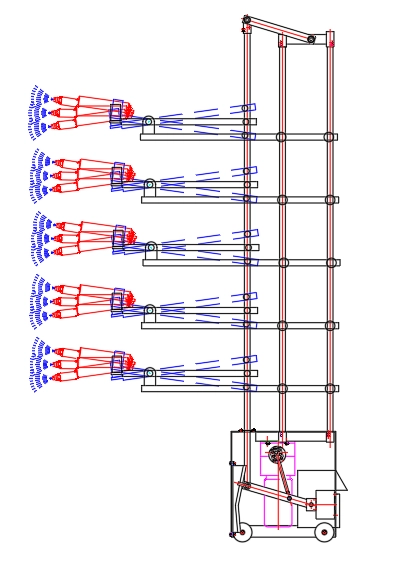

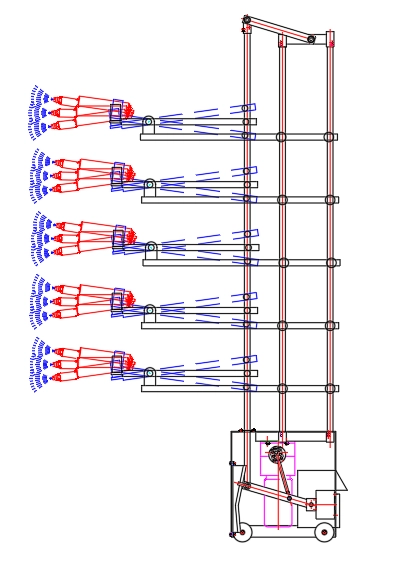

How Automatic Electrostatic Spray Guns Work

These spray guns charge coating particles electrically and propel them toward a grounded object. The electrostatic attraction improves transfer efficiency, ensuring paint or coating droplets adhere better, reducing overspray and waste.

Advantages in Production Lines

- Improved coating transfer efficiency up to 90%, reducing paint usage

- Enhanced uniformity and finish quality with fewer defects

- Faster coating cycles and higher throughput

- Reduced environmental impact due to less overspray and VOC emissions

Understanding these benefits helps in planning optimal integration into production operations.

Planning for Integration

Proper planning is critical to ensure effective implementation and operation of automatic electrostatic spray guns.

Assessing Current Production Line Compatibility

Evaluate existing equipment, line speed, conveyor type, and product size to determine if automatic electrostatic spray guns can be accommodated without bottlenecks or quality issues.

Defining Clearly the Coating Requirements

Specify coating types, thickness, drying time, and environmental conditions. These details influence gun settings, position, and automation requirements.

Evaluating Infrastructure Needs

Ensure adequate electrical supply, grounding provisions, ventilation, and workspace layout to support electrostatic equipment safely and efficiently.

Equipment Selection and Configuration

Choosing the right equipment and configuring it properly forms the foundation of successful integration.

Selecting Suitable Electrostatic Guns

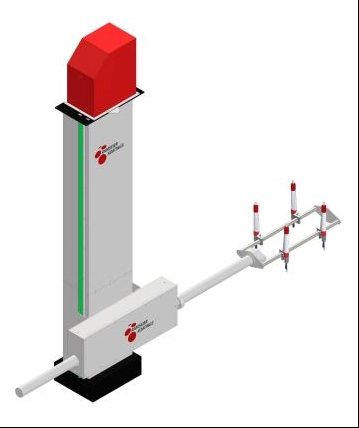

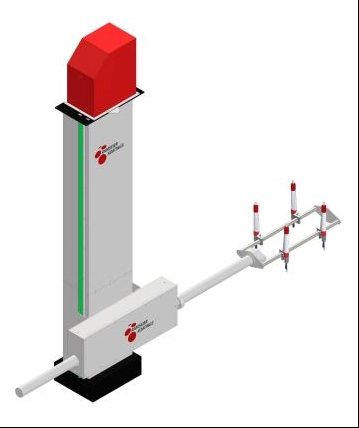

Match the guns to product geometry, line speed, and coating viscosity. Consider automatic guns with adjustable voltage, flow rates, and programmable patterns for flexibility.

Integration with Automation Systems

Ensure compatibility with robotic arms or conveyors and communication protocols such as PLC or industrial Ethernet for seamless operation control.

Positioning and Mounting

Strategically mount the spray guns to optimize coverage while maintaining reachable maintenance access. Adjustable mounts facilitate fine-tuning during startup phases.

Installation Best Practices

Executing installation with attention to detail prevents performance issues later.

Grounding and Electrical Safety

Establish robust grounding of all components to prevent static discharge hazards and ensure consistent electrostatic effect. Use dedicated grounding points and conduct regular inspections.

Environmental Controls

Install proper ventilation and filtration to handle overspray and maintain operator safety. Temperature and humidity control improve coating consistency.

Calibration and Initial Setup

Conduct thorough calibration to set voltage, spray pattern, and flow rate precisely for the specific product and coating. Use test panels and adjust incrementally.

Operator Training and Maintenance

Skilled operators and routine maintenance are essential for sustained success.

Comprehensive Operator Training

Train staff on equipment functions, safety protocols, cleaning procedures, and troubleshooting. Emphasize the importance of coating material handling and personal protective equipment.

Scheduled Maintenance and Cleaning

Implement a maintenance schedule including daily cleaning of nozzle tips, weekly inspection of electrical connections, and periodic replacement of wear parts to maintain optimal performance.

Monitoring and Troubleshooting Tools

Use technology like current meters, flow sensors, and spray pattern analyzers to identify issues early and minimize downtime.

Process Optimization and Quality Control

Fine-tuning the process enhances efficiency and product quality over time.

Integrating Feedback Systems

Deploy sensors to monitor coating thickness, line speed, and environmental conditions, feeding data into control systems for real-time adjustments.

Conducting Routine Quality Checks

Regular inspection of coated products for adhesion, thickness uniformity, and aesthetics helps identify deviations early.

Continuous Improvement Strategies

Analyze process data trends to optimize parameters, reduce waste, and improve coating consistency.

Case Studies of Successful Integration

Illustrating real-world examples helps solidify the best practices.

Automotive Component Manufacturing

A major OEM implemented automatic electrostatic spray guns integrated with a robotic conveyor system, reducing paint waste by 40% and increasing throughput by 25%.

Furniture Production Line

Integration of electrostatic guns in a wooden furniture line achieved more uniform finishes and shortened drying times, enhancing output without additional labor costs.

Challenges and Solutions

Recognizing common obstacles prepares manufacturers to address them proactively.

Managing Complex Part Geometries

Solution: Use programmable spray patterns and multi-axis robotic arms to ensure full coverage.

Ensuring Worker Safety

Solution: Install interlocks, ventilation, and use grounded PPE; provide rigorous training.

Minimizing Downtime

Solution: Maintain inventory of critical spare parts, implement predictive maintenance technologies.

Future Trends in Electrostatic Spray Technology

Awareness of upcoming advancements helps companies stay competitive.

Smart Spray Systems

Integration with AI and machine learning for adaptive spray control and predictive maintenance.

Eco-Friendly Coatings and Equipment

Development of low-volatile organic compound (VOC) coatings and compact, energy-efficient spray systems.

Enhanced Automation and Integration

Greater use of sensors, robotics, and networked devices for fully agile production lines.

FAQ about Automatic Electrostatic Spray Gun Integration

Q1: What types of coatings can be applied using automatic electrostatic spray guns?

A1: They are compatible with a wide range of coatings, including paints, powders, lacquers, and varnishes, depending on equipment configuration.

Q2: How important is grounding in an electrostatic spray system?

A2: Extremely important; proper grounding prevents electrical hazards and ensures the electrostatic charge attracts coating particles effectively.

Q3: Can automatic electrostatic spray guns be used on all product shapes?

A3: They work best on conductive and shaped parts. For complex geometries, automated multi-axis spraying systems improve coverage.

Q4: What maintenance practices are essential for these spray guns?

A4: Daily nozzle cleaning, regular electrical inspections, and timely replacement of worn parts are critical to sustained performance.

Q5: How does electrostatic spraying reduce environmental impact?

A5: By increasing transfer efficiency, it reduces overspray and paint waste, lowering volatile organic compound emissions.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.