Content Menu

● Understanding Automated Powder Coating

>> Benefits of Automation in Powder Coating

● The Importance of Data Management in Automated Powder Coating

>> Enhancing Process Control and Monitoring

>> Quality Control and Predictive Maintenance

>> Traceability and Compliance

● Implementing Effective Data Management Solutions

>> Data Collection Technologies

>> Data Storage and Organization

>> Advanced Analytics and Visualization

>> Integration with Manufacturing Execution Systems (MES)

● Data-Driven Advantages in Powder Coating Automation

>> Increased Operational Efficiency

>> Improved Product Quality and Consistency

>> Enhanced Sustainability

>> Better Decision-Making and Continuous Improvement

● Challenges and Considerations in Data Management for Powder Coating

>> Data Volume and Complexity

>> Cybersecurity and Data Integrity

>> Integrating Legacy Equipment

>> Staff Training and Change Management

● Future Trends in Data Management and Automated Powder Coating

>> Artificial Intelligence and Machine Learning

>> Edge Computing

>> Digital Twins

>> Blockchain for Traceability

● Frequently Asked Questions

In modern manufacturing industries, automated powder coating has become a critical process for enhancing product durability and aesthetics. The efficiency and quality of these operations increasingly depend on sophisticated data management systems. This article explores the essential role that data management plays in automated powder coating, examining how it improves operational efficiency, quality control, traceability, and sustainability.

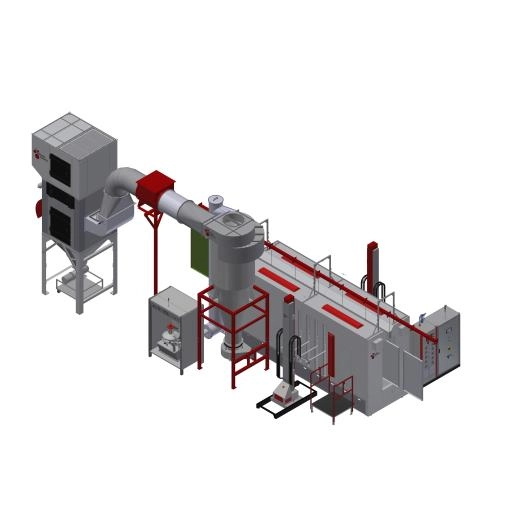

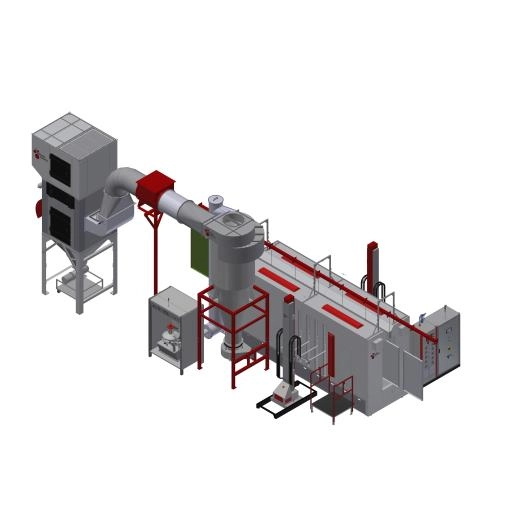

Understanding Automated Powder Coating

Automated powder coating refers to the use of programmed machinery and robotics to apply powder coatings on various surfaces, primarily metals. Unlike traditional liquid coatings, powder coating uses electrostatically charged powder particles that adhere to the surface and are then cured under heat to form a hard finish. Automation enhances consistency and throughput while reducing labor costs.

Benefits of Automation in Powder Coating

- Consistency: Robots and automated systems apply powder evenly, minimizing defects.

- Speed: Automation allows faster cycle times and higher production volumes.

- Reduced Waste: Precise application decreases powder overspray and waste.

- Improved Safety: Automation minimizes workers' exposure to coating powders and curing ovens.

However, automating such a complex process generates large volumes of data that must be effectively captured, analyzed, and utilized to optimize outcomes. This is where data management becomes indispensable.

The Importance of Data Management in Automated Powder Coating

Data management involves collecting, storing, organizing, and analyzing data to support decision-making. In automated powder coating, data originates from multiple sources such as machinery sensors, production logs, quality inspection stations, and environmental monitoring systems.

Enhancing Process Control and Monitoring

One of the core functions of data management is to enable precise process control. Real-time data collection from automated powder coaters allows operators to monitor parameters like powder feed rate, spray gun voltage, conveyor speed, curing temperature, and humidity.

Through central data management platforms, anomalies can be quickly detected. For example, a drop in spray gun voltage or a rise in curing oven temperature outside preset limits triggers automatic alerts, allowing immediate corrective actions to prevent defects.

Quality Control and Predictive Maintenance

Data collected during powder coating operations supports stringent quality control. Historical production data enables correlation between specific process parameters and product quality outcomes, identifying those factors most critical to producing defect-free coatings.

Advanced data analytics can also predict maintenance needs by tracking equipment usage patterns and sensor readings. Predictive maintenance minimizes downtime by scheduling service before breakdowns occur, maintaining consistent productivity and coating quality.

Traceability and Compliance

In many industries, traceability from raw material input through to finished coated product is mandatory, especially for automotive, aerospace, and medical sectors. Data management systems maintain detailed records such as batch numbers of powders, machine settings, operator IDs, and inspection results.

Traceability aids in compliance with regulatory standards, supports product recalls or investigations, and boosts customer confidence by documenting quality assurance.

Implementing Effective Data Management Solutions

To fully leverage data management in automated powder coating, manufacturers must implement integrated hardware and software solutions capable of capturing, storing, analyzing, and visualizing data comprehensively.

Data Collection Technologies

- Sensors and IoT Devices: These capture process variables in real time, feeding data into central systems.

- Machine Interfaces: PLCs and HMIs communicate equipment status and operational metrics.

- Barcode and RFID Scanners: These track materials and product flow throughout the coating line.

Data Storage and Organization

Cloud-based or on-premises database systems store large amounts of data securely, ensuring accessibility for analysis. Structured data organization allows quick retrieval, sorting by date, machine, operator, or product batch.

Advanced Analytics and Visualization

Data management platforms integrate analytics tools such as machine learning algorithms, statistical process control charts, and dashboards. These enable users to detect trends, predict issues, and generate reports that support continuous improvement.

Integration with Manufacturing Execution Systems (MES)

MES integration allows seamless coordination between powder coating operations and broader manufacturing workflows. This provides a holistic view of production performance and enables better scheduling and resource allocation decisions.

Data-Driven Advantages in Powder Coating Automation

Increased Operational Efficiency

By constantly monitoring and adjusting process parameters based on data feedback, manufacturers reduce downtime, rework, and defective output. This leads to higher throughput and lower operational costs.

Improved Product Quality and Consistency

Real-time data ensures every product receives the correct coating specifications, minimizing variability. Historical data analysis drives process standardization and refinement.

Enhanced Sustainability

Data management helps optimize powder usage and energy consumption within curing ovens. Monitoring powder overspray and reclaiming excess material reduce waste. Energy-efficient curing cycles also lower environmental impact.

Better Decision-Making and Continuous Improvement

Accessible and understandable data facilitates informed decision-making at all levels. From operators adjusting process settings to managers planning capacity, data insights foster a culture of continuous improvement.

Challenges and Considerations in Data Management for Powder Coating

Despite its benefits, implementing data management in automated powder coating presents challenges.

Data Volume and Complexity

Automated powder coating lines generate massive volumes of data from varied sources with different formats. Managing this complexity requires robust infrastructure and skilled data analysts.

Cybersecurity and Data Integrity

Protecting sensitive production data from cyber threats is critical. Data must be encrypted, access controlled, and regularly backed up to prevent losses or tampering.

Integrating Legacy Equipment

Older powder coating machinery may lack modern data interfaces, requiring retrofits or middleware solutions for integration into digital systems.

Staff Training and Change Management

Operators and managers need training to effectively use data management tools and understand analytics outputs. Additionally, organizational culture must adapt to embrace data-driven decision-making.

Future Trends in Data Management and Automated Powder Coating

The role of data management in automated powder coating is expected to grow with emerging technologies.

Artificial Intelligence and Machine Learning

AI-powered analytics can discover deeper insights, optimize complex parameter interactions, and autonomously adjust coating operations for maximum performance.

Edge Computing

Processing data locally at the powder coating line reduces latency, enabling faster real-time responses and decreasing bandwidth dependency.

Digital Twins

Creating virtual models of powder coating systems allows simulation and testing of process changes virtually, reducing trial-and-error and speeding up innovation.

Blockchain for Traceability

Blockchain technology can provide tamper-proof, decentralized records of coating data, enhancing traceability and trust across supply chains.

Frequently Asked Questions

1. Why is data management critical in automated powder coating?

Data management allows real-time monitoring, quality control, and process optimization, leading to improved product quality and operational efficiency.

2. What types of data are collected during powder coating operations?

Data includes process parameters (spray rate, voltage, temperature), environmental conditions, machine status, material batch numbers, and inspection results.

3. How does data management support predictive maintenance?

Analyzing equipment sensor data can predict when maintenance is needed before failures occur, minimizing downtime.

4. Can data management help reduce waste in powder coating?

Yes. By tracking powder usage and process parameters, manufacturers optimize material use and reclaim overspray, reducing waste.

5. What challenges should companies expect when implementing data management systems?

Challenges include managing data volume and complexity, integrating with legacy equipment, addressing cybersecurity, and training staff.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.