Content Menu

● Understanding Powder Coating Spray Gun Units

>> What is a Powder Coating Spray Gun Unit?

>> Types of Spray Gun Units for Powder Coating

● Components of a Powder Coating Spray Gun Unit

>> Powder Feed System

>> Electrostatic Charging Mechanism

>> Nozzle Assembly

● Best Practices for Using Spray Gun Units

>> Preparing the Equipment

>> Operating the Spray Gun

>>> Spray Technique

>>> Environment Considerations

● Tips for Improving Powder Coating Quality

>> Selecting the Right Powder and Gun Combination

>> Regular Maintenance

>> Troubleshooting Common Issues

● Advancements and Innovations in Spray Gun Units

>> Automated and Robotic Spray Guns

>> Smart Spray Guns with Feedback Systems

>> Eco-Friendly and Energy-Efficient Features

● Safety Tips When Using Powder Coating Spray Guns

● Frequently Asked Questions (FAQs)

>> 1. What voltage should I use on my powder coating spray gun?

>> 2. How often should I clean the spray gun unit?

>> 3. Can I use the same spray gun for different types of powders?

>> 4. How do I reduce powder waste during spraying?

>> 5. What are the common causes of orange peel texture in powder coating?

Powder coating is a widely used finishing process in manufacturing, valued for its durability, environmental friendliness, and aesthetic appeal. A critical component of this process is the spray gun unit, which directly affects the quality, efficiency, and consistency of the powder coating. Understanding how to select, operate, and maintain spray gun units is essential for achieving optimal results. This comprehensive guide covers everything you need to know about spray gun units for powder coating, including best practices, tips, and troubleshooting advice.

Understanding Powder Coating Spray Gun Units

What is a Powder Coating Spray Gun Unit?

A spray gun unit is a specialized tool designed to apply powder coating materials to various surfaces. It atomizes the powder particles and charges them electrostatically, allowing the powder to adhere uniformly to the grounded workpiece. The unit typically consists of a powder feed system, an electrostatic charging mechanism, and a spray nozzle.

Types of Spray Gun Units for Powder Coating

There are several types of powder coating spray guns, each suited for different applications:

- Corona Charging Guns: The most common type, they use high voltage to charge the powder particles.

- Triboelectric Charging Guns: These charge powder particles by friction instead of high voltage.

- Automatic vs. Manual Guns: Automatic guns are mounted on robotic arms for high-volume production, while manual guns are hand-held for flexibility.

Components of a Powder Coating Spray Gun Unit

Powder Feed System

The powder feed system transports the powder from the hopper to the spray gun nozzle. The system needs to ensure a consistent flow of powder to avoid thin or thick spots on the surface.

- Vibratory Feeders: Use vibration to move powder.

- Peristaltic Pumps: Use flexible tubing to pump powder through.

- Pressure or Vacuum Feed Systems: Use air pressure differences to convey powder.

Electrostatic Charging Mechanism

Charging powder particles electrostatically is crucial for powder adhesion. The charging unit creates a strong electric field between the spray gun and the grounded part.

- Electrode Design: A fine needle or wire charges the powder.

- Voltage Settings: Typically between 50-100 kV depending on the gun and application.

Nozzle Assembly

The spray nozzle controls the pattern shape and size, directly affecting coating uniformity and efficiency.

- Flat Jet Nozzles: Produce wide, even patterns.

- Round Nozzles: Offer circular spray patterns for detailed work.

- Adjustable Nozzles: Allow operators to modify the spray width and angle during application.

Best Practices for Using Spray Gun Units

Preparing the Equipment

Proper setup ensures optimal performance:

- Clean the Gun Regularly: Powder buildup can cause clogging and inconsistent spray patterns.

- Check Electrodes: Inspect for wear or contamination frequently.

- Set Correct Voltage: Adjust power carefully to match powder type and workpiece geometry.

- Ensure Proper Grounding: A well-grounded workpiece improves powder attraction and reduces bounce-back.

Operating the Spray Gun

Spray Technique

- Maintain Consistent Distance: Usually 8-12 inches between gun and surface.

- Use Smooth, Even Strokes: Prevent over-application and uneven coverage.

- Overlap Passes: By about 50% to avoid stripes or missed areas.

- Control Air Pressure: Too high can cause powder dispersion; too low may reduce transfer efficiency.

Environment Considerations

- Humidity Control: High moisture in the air can cause clumping or poor adhesion.

- Temperature: Ideal spray temperature typically ranges 20-25°C for best results.

- Ventilation: Proper airflow removes excess powder and prevents contamination.

Tips for Improving Powder Coating Quality

Selecting the Right Powder and Gun Combination

Different powders have varying particle sizes and flow characteristics, so pairing them with the correct spray gun improves coating quality.

- Fine Powders: Require fine orifices and precise voltage control.

- Bulk Powders: May benefit from robust feed systems with higher air pressure.

Regular Maintenance

- Routine Inspection: Check hoses, seals, and electrical connections.

- Replace Worn Parts: Electrodes and nozzles degrade and need timely replacement.

- Calibration: Periodically verify system settings for voltage and powder feed rates.

Troubleshooting Common Issues

- Poor Coverage or Thin Spots: Adjust gun distance and powder flow rate.

- Orange Peel Effect (Textured Surface): Check spray parameters and powder type.

- Powder Clumping or Clogging: Ensure moisture control and clean feed lines.

- Excessive Bounce-back: Improve grounding and raise voltage carefully.

Advancements and Innovations in Spray Gun Units

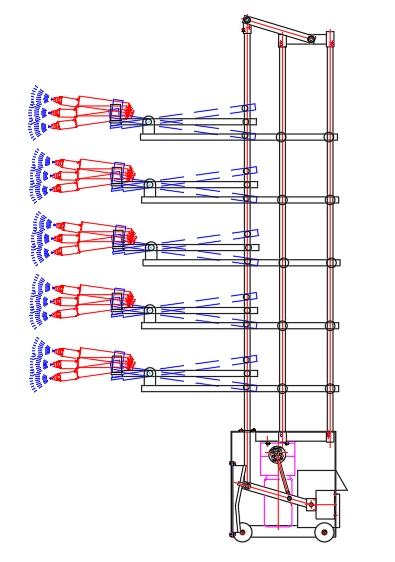

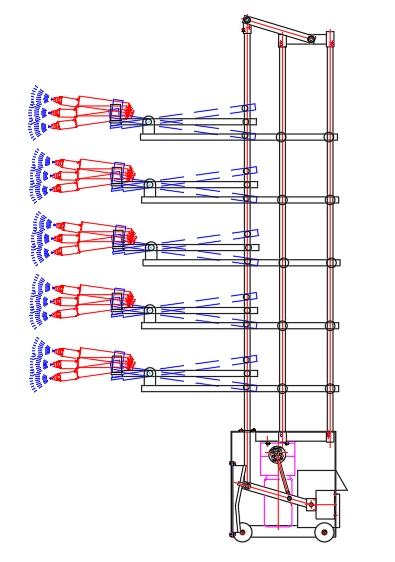

Automated and Robotic Spray Guns

Robotics integration boosts productivity by consistently replicating optimal spray paths and speeds, reducing operator variability.

Smart Spray Guns with Feedback Systems

Modern guns equipped with sensors provide real-time data on flow rates, voltage, and environmental conditions, enabling immediate adjustments and improving process control.

Eco-Friendly and Energy-Efficient Features

New designs reduce powder waste and improve transfer efficiency, minimizing environmental impact and operational costs.

Safety Tips When Using Powder Coating Spray Guns

- Wear Appropriate PPE: Respirators, gloves, and protective clothing.

- Avoid Inhalation of Powders: Fine powders can pose respiratory hazards.

- Ground All Equipment: To prevent static discharge or sparks.

- Follow Manufacturer Guidelines: For voltage and airflow settings to prevent damage or injury.

Frequently Asked Questions (FAQs)

1. What voltage should I use on my powder coating spray gun?

The voltage depends on the powder type and workpiece characteristics but typically ranges from 50,000 to 100,000 volts. Start low and gradually increase until you achieve good adhesion without excessive bounce-back.

2. How often should I clean the spray gun unit?

Clean the gun at least daily during use, especially the nozzle, electrodes, and powder feed lines, to prevent clogging and maintain uniform spray patterns.

3. Can I use the same spray gun for different types of powders?

Some guns are versatile, but it is best to use guns compatible with specific powder characteristics to avoid inconsistent coatings or equipment wear.

4. How do I reduce powder waste during spraying?

Ensure proper grounding, maintain consistent gun-to-part distance, use correct voltage, and select nozzles that minimize overspray. Automation can also reduce waste significantly.

5. What are the common causes of orange peel texture in powder coating?

Orange peel texture can result from improper spray parameters, incorrect gun distance, inappropriate powder selection, or poor curing processes. Adjust the equipment settings and verify powder compatibility.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.