Content Menu

● Understanding Industrial Spray Guns

>> What Is an Industrial Spray Gun?

>> Types of Spray Guns for Industrial Use

● Key Factors for Choosing the Best Industrial Spray Gun

>> Coating Material Compatibility

>> Spray Gun Design and Durability

>> Spray Pattern and Control

>> Pressure and Air Supply Requirements

>> Nozzle and Atomizing Head Sizes

>> Type of Operation: Manual, Automatic, or Semi-Automatic

● Practical Considerations for Industrial Spray Gun Selection

>> Environmental and Safety Regulations

>> Cost of Ownership

>> Vendor Support and Accessories

● Popular Industrial Spray Gun Systems

>> 3M™ Performance Spray Gun

>> Buffalo Tools Industrial Paint Spray Gun

>> Graco Spray Guns

● Maintenance Tips for Industrial Spray Guns

● Frequently Asked Questions

>> 1. What type of spray gun is best for high-viscosity coatings?

>> 2. How does HVLP technology benefit industrial spraying?

>> 3. Can I use one spray gun for multiple types of coatings?

>> 4. What maintenance is critical for prolonging spray gun life?

>> 5. Are automatic spray guns suitable for all industrial applications?

In industrial settings, spray gun units are essential tools for applying coatings efficiently and uniformly. Choosing the right spray gun can significantly affect the quality of finishes, productivity, cost-effectiveness, and operator satisfaction. This comprehensive guide covers everything industrial users need to know to select the best spray gun unit tailored to their specific needs.

Understanding Industrial Spray Guns

What Is an Industrial Spray Gun?

An industrial spray gun is a mechanical device that atomizes liquid coatings such as paints, primers, adhesives, or protective finishes into a fine mist to be evenly applied over surfaces. Unlike brushes or rollers, spray guns deliver faster, more uniform coverage, especially over large or complicated surfaces, increasing throughput and improving finish quality.

Types of Spray Guns for Industrial Use

- Air Spray Guns: Use compressed air to atomize coatings. They deliver a fine finish but produce more overspray and require higher air pressure.

- HVLP (High Volume Low Pressure) Spray Guns: Minimize overspray by using a high volume of air at low pressure. They are efficient and environmentally friendly.

- Airless Spray Guns: Use high pressure to atomize material without compressed air, suitable for high-viscosity coatings and large surfaces.

- Electrostatic Spray Guns: Charge the paint particles electrically, improving transfer efficiency by attracting coating to the grounded surface.

Choosing among these depends on the coating type, surface characteristics, finish quality requirements, and environmental considerations.

Key Factors for Choosing the Best Industrial Spray Gun

Coating Material Compatibility

Different spray guns and nozzles handle various coating materials better. For example, epoxy, urethane, base coats, top coats, primers, adhesives, and stains each have unique viscosities and chemical properties. Ensure that the spray gun unit supports the coatings you intend to use. Some systems, like the 3M™ Performance Spray Gun, come with interchangeable atomizing heads designed for a range of coatings, maximizing versatility.

Spray Gun Design and Durability

Industrial environments demand robust, comfortable spray guns:

- Material: Composite-bodied spray guns offer lightweight handling with impact resistance, reducing operator fatigue during long shifts.

- Ergonomics: Optimized grip, trigger design, and weight distribution enhance comfort and control.

- Maintenance: Fewer parts and easy-to-replace nozzles prolong operational life and reduce downtime.

For instance, advanced models are designed by kinesiologists for ergonomic efficiency, making them easier to use all day long.

Spray Pattern and Control

A spray gun that provides adjustable spray patterns (such as circular, oval, or horizontal) and volume control allows for greater precision and efficiency. This adaptability lets operators tailor the spray to the job, whether doing detailed work or covering large industrial surfaces.

Pressure and Air Supply Requirements

Check the operating pressure and air consumption to ensure compatibility with your facility's compressed air system or pressure pot. Industrial spray guns often require pressures from 50 to 70 psi, with air consumption rates depending on nozzle size and spray type.

Nozzle and Atomizing Head Sizes

Nozzle size affects spray width, material flow, and finish quality. Industrial models typically offer quick-change nozzles ranging in size for different coatings and spray characteristics, providing the flexibility to switch effortlessly between tasks.

Type of Operation: Manual, Automatic, or Semi-Automatic

- Manual Spray Guns: Offer technician control for small to medium jobs or spot repairs.

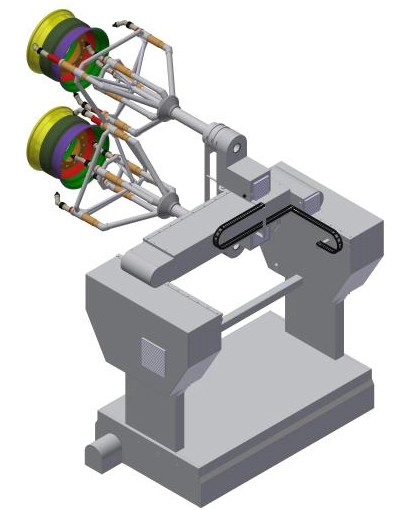

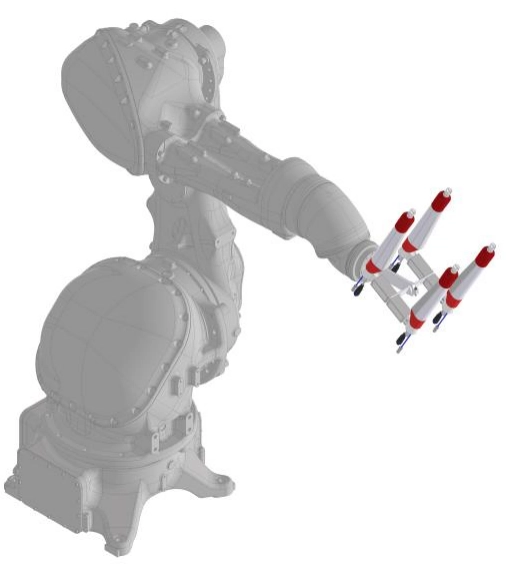

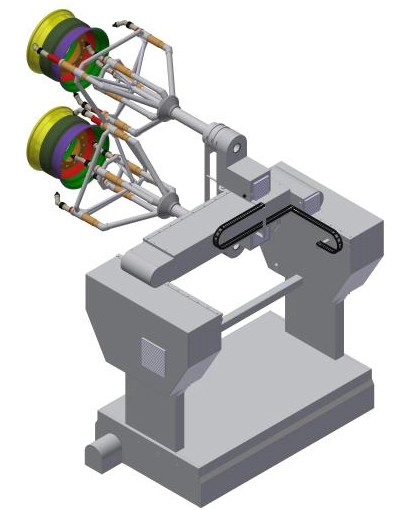

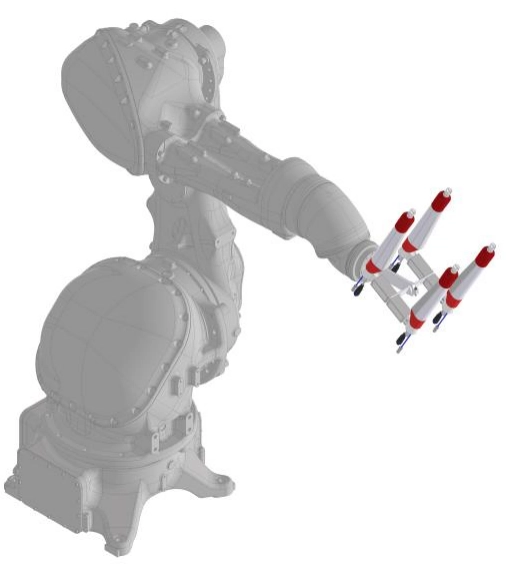

- Automatic Spray Guns: Integrated into production lines or robotic arms for continuous, uniform application on mass-produced parts.

- Semi-Automatic: Hybrid systems balancing automation with manual control for versatile applications.

Decide based on production volume, automation level, and budget.

Practical Considerations for Industrial Spray Gun Selection

Environmental and Safety Regulations

HVLP guns reduce air pollution and overspray, helping meet environmental standards. Ensure your spray gun unit complies with occupational health guidelines to protect operators from fumes and overspray exposure.

Cost of Ownership

Balance upfront investment with maintenance costs, consumables (like nozzles), and energy consumption. Durable composite spray guns might cost more initially but save money on repairs and operator downtime.

Vendor Support and Accessories

Choose suppliers offering comprehensive support, replacement parts, and accessories like spray cups, filters, and hose adapters. Systems that integrate seamlessly with existing facilities are advantageous.

Popular Industrial Spray Gun Systems

3M™ Performance Spray Gun

Lightweight and durable, it features impact-resistant composite design, interchangeable nozzles from 1.1 to 2.0 sizes, and the option for pressure pot or gravity cup operation. It is optimized for a wide range of coatings, including primers, base coats, top coats, clear coats, epoxy, and adhesives. Its ergonomic design helps reduce operator fatigue while maintaining consistent performance.

Buffalo Tools Industrial Paint Spray Gun

Offers a 1-quart aluminum cup, adjustable spray pattern, and volume control. Operates at 50-70 psi with a 2.0 mm nozzle, suitable for detailed painting and industrial applications requiring a quality finish.

Graco Spray Guns

Known for versatility in finishing metals, plastics, and wood, Graco manual and automatic spray guns provide durability and precision in industrial manufacturing environments.

Maintenance Tips for Industrial Spray Guns

- Regularly clean nozzles and atomizing heads to prevent clogging.

- Replace worn parts promptly to maintain consistent spray quality.

- Use compatible cleaning agents per coating type.

- Lubricate moving parts as recommended by the manufacturer.

Proper maintenance extends equipment life and ensures reliable performance.

Frequently Asked Questions

1. What type of spray gun is best for high-viscosity coatings?

Airless spray guns are generally preferred for high-viscosity materials, as they use high pressure to atomize thicker coatings without compressed air.

2. How does HVLP technology benefit industrial spraying?

HVLP guns reduce overspray and waste, improving transfer efficiency and reducing environmental impact while delivering excellent finish quality.

3. Can I use one spray gun for multiple types of coatings?

Some spray guns with interchangeable nozzles and atomizing heads can handle various coatings, but always verify compatibility to avoid clogging and poor finish.

4. What maintenance is critical for prolonging spray gun life?

Regular cleaning, prompt replacement of parts, proper lubrication, and using appropriate cleaning solvents are essential for spray gun longevity.

5. Are automatic spray guns suitable for all industrial applications?

Automatic spray guns are best for high-volume, consistent applications like assembly lines but may not be ideal for detailed or custom jobs requiring human control.

[1] https://www.3m.com/3M/en_US/collision-repair-us/featured-products/spray-gun/performance-spray-gun/

[2] http://www.cupl.cc/kyyyzhenti.html

[3] https://www.buffalocorpstore.com/product/buffalo-tools-1-quart-industrial-paint-spray-gun/

[4] https://www.finishsystems.com/collections/industrial/spray-guns

[5] https://www.titantool.com

[6] https://www.graco.com/us/en/in-plant-manufacturing/products/liquid-coating/spray-booth/spray-guns-applicators.html

[7] https://www.blastone.com/product-category/painting/airless-spray-systems/

[8] https://www.sames.com/usa/en/families-manual-guns.html

[9] https://www.grainger.com/category/paints-equipment-and-supplies/painting-equipment/paint-spray-guns-systems

[10] https://sprayequipment.com

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.