Content Menu

● Understanding Spray Booths

>> What is a Spray Booth?

>> Types of Spray Booths

● Key Differences Between Automatic and Manual Spray Booths

>> 1. Efficiency and Speed

>>> Automatic Spray Booths

>>> Manual Spray Booths

>> 2. Quality of Finish

>>> Automatic Spray Booths

>>> Manual Spray Booths

>> 3. Cost Considerations

>>> Initial Investment

>>> Operating Costs

>> 4. Flexibility and Customization

>>> Automatic Spray Booths

>>> Manual Spray Booths

>> 5. Maintenance and Upkeep

>>> Automatic Spray Booths

>>> Manual Spray Booths

● Choosing the Right Spray Booth for Your Needs

>> 1. Project Volume and Type

>> 2. Budget Constraints

>> 3. Skill Level of Operators

>> 4. Space Availability

>> 5. Future Growth

● Conclusion

● Frequently Asked Questions

>> 1. What is the main advantage of automatic spray booths?

>> 2. Are manual spray booths more cost-effective?

>> 3. Can I use an automatic booth for custom jobs?

>> 4. How often do automatic spray booths require maintenance?

>> 5. What should I consider when choosing a spray booth?

When it comes to spray painting, whether for automotive refinishing, industrial applications, or custom projects, the choice of spray booth can significantly impact the quality of the finish, efficiency of the operation, and overall costs. This article explores the differences between swinger automatic spray booths and manual booths, helping you make an informed decision based on your specific needs.

Understanding Spray Booths

What is a Spray Booth?

A spray booth is a controlled environment designed for applying paint or coatings to various surfaces. It provides a safe and efficient workspace by containing overspray, controlling airflow, and ensuring proper ventilation. Spray booths can be categorized into two main types: automatic and manual.

Types of Spray Booths

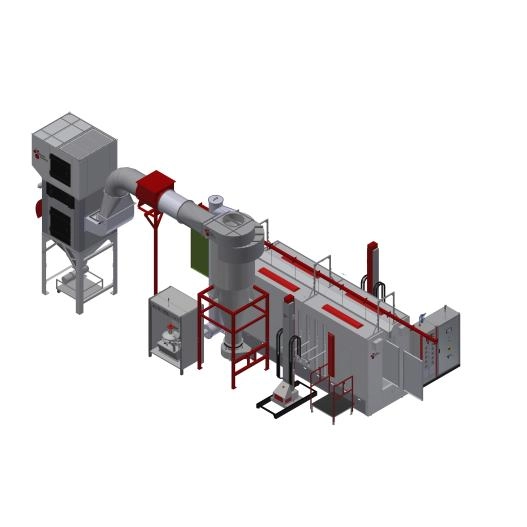

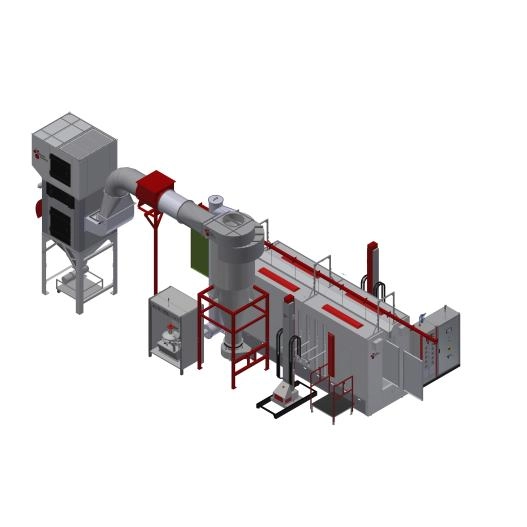

1. Automatic Spray Booths: These booths utilize automated systems to apply paint. They often include robotic arms or automated spray guns that ensure consistent application and reduce human error.

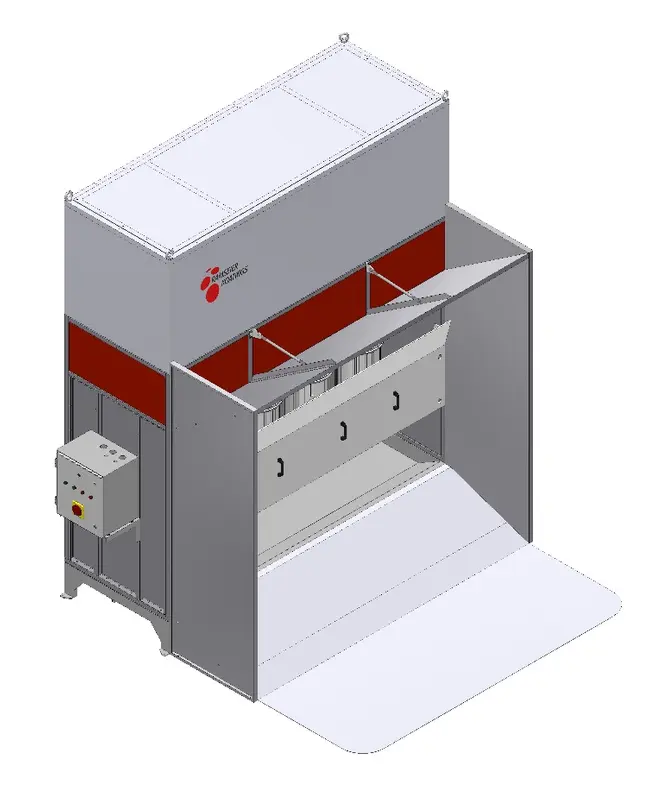

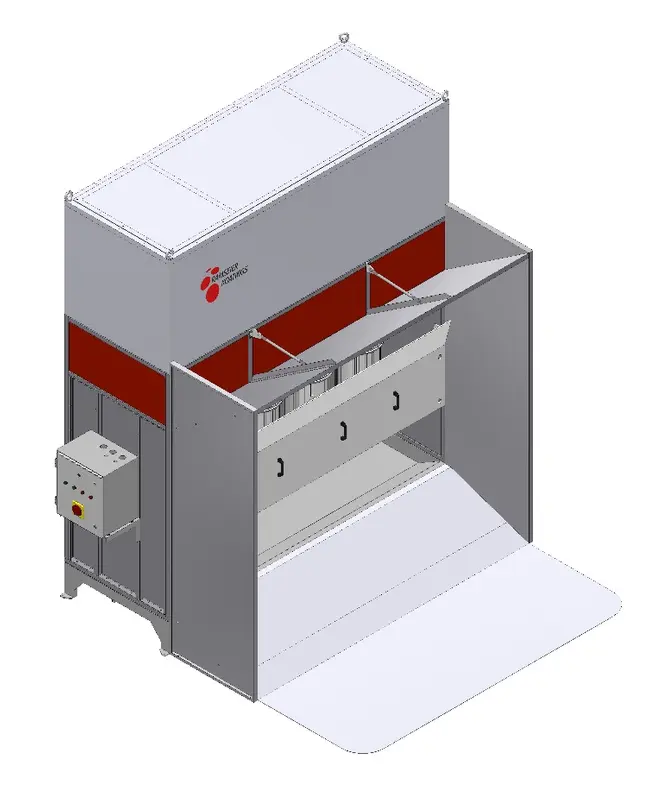

2. Manual Spray Booths: In these booths, operators manually control the spray guns. This type allows for greater flexibility and is often preferred for custom jobs where precision is key.

Key Differences Between Automatic and Manual Spray Booths

1. Efficiency and Speed

Automatic Spray Booths

Automatic spray booths are designed for high efficiency. They can operate continuously, applying paint at a faster rate than manual booths. This is particularly beneficial for large-scale operations where time is critical. The automation reduces the time spent on each job, allowing for quicker turnaround times.

Manual Spray Booths

Manual booths, while versatile, typically require more time for each application. The speed of operation depends heavily on the skill and experience of the operator. For smaller projects or custom jobs, this may not be a significant drawback, but for larger operations, it can lead to delays.

2. Quality of Finish

Automatic Spray Booths

One of the primary advantages of automatic spray booths is the consistency of the finish. Automated systems can apply paint with precision, ensuring an even coat without the variability that can come from human application. This is particularly important in industries where uniformity is crucial.

Manual Spray Booths

Manual booths allow for a more hands-on approach, which can be beneficial for intricate designs or custom finishes. Skilled operators can adjust their technique based on the specific requirements of the job, potentially achieving a higher quality finish for unique projects.

3. Cost Considerations

Initial Investment

Automatic spray booths generally require a higher initial investment due to the cost of the technology and equipment involved. This includes robotic systems, advanced controls, and sometimes more complex installation requirements.

Operating Costs

While the upfront costs are higher, automatic booths can lead to lower operating costs over time. They reduce labor costs by minimizing the number of operators needed and can decrease material waste through more efficient application techniques.

Manual booths, on the other hand, have lower initial costs but may incur higher labor costs due to the need for skilled operators and the potential for more material waste.

4. Flexibility and Customization

Automatic Spray Booths

Automatic booths are less flexible than manual booths. They are typically set up for specific tasks and may require reconfiguration for different types of jobs. This can be a limitation for businesses that handle a wide variety of projects.

Manual Spray Booths

Manual booths offer greater flexibility. Operators can easily switch between different types of jobs, making them ideal for businesses that require customization and adaptability. This is particularly advantageous for small shops that handle diverse projects.

5. Maintenance and Upkeep

Automatic Spray Booths

The maintenance of automatic spray booths can be more complex due to the technology involved. Regular servicing is essential to ensure that the robotic systems and controls function correctly. However, many manufacturers provide support and maintenance services to assist with this.

Manual Spray Booths

Manual booths are generally easier to maintain. With fewer moving parts and simpler technology, they can often be serviced by in-house staff. This can lead to lower maintenance costs over time.

Choosing the Right Spray Booth for Your Needs

When deciding between a swinger automatic spray booth and a manual booth, consider the following factors:

1. Project Volume and Type

If your business handles high volumes of similar projects, an automatic spray booth may be the best choice. For custom work or lower volumes, a manual booth may be more suitable.

2. Budget Constraints

Evaluate your budget not only for the initial purchase but also for ongoing operational costs. Automatic booths may require a larger upfront investment but can save money in the long run.

3. Skill Level of Operators

Consider the skill level of your operators. If you have highly skilled painters, a manual booth may allow for better customization. If your workforce is less experienced, an automatic booth can help ensure consistent quality.

4. Space Availability

Automatic spray booths often require more space due to their size and the need for additional equipment. Ensure that your facility can accommodate the booth you choose.

5. Future Growth

Think about your business's future needs. If you anticipate growth or changes in the types of projects you handle, consider a booth that can adapt to those changes.

Conclusion

Choosing between swinger automatic spray booths and manual booths involves weighing the pros and cons of each option based on your specific needs. Automatic booths offer efficiency, consistency, and lower long-term costs, making them ideal for high-volume operations. Manual booths provide flexibility and customization, making them suitable for smaller, diverse projects. By carefully considering your operational requirements, budget, and future growth, you can make an informed decision that best suits your business.

Frequently Asked Questions

1. What is the main advantage of automatic spray booths?

Automatic spray booths provide consistent quality and efficiency, making them ideal for high-volume production.

2. Are manual spray booths more cost-effective?

While manual spray booths have lower initial costs, they may incur higher labor costs and material waste over time.

3. Can I use an automatic booth for custom jobs?

Yes, but automatic booths are typically set up for specific tasks, which may limit flexibility for highly customized projects.

4. How often do automatic spray booths require maintenance?

Maintenance frequency depends on usage, but regular servicing is essential to keep the robotic systems functioning properly.

5. What should I consider when choosing a spray booth?

Consider project volume, budget, operator skill level, space availability, and future growth when selecting a spray booth.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.