Content Menu

● Understanding Powder Coating and Its Challenges

● What Are Smart Control Systems?

● How Smart Control Systems Enhance Powder Coating Productivity

>> Precise and Consistent Application

>> Efficient Material Management

>> Streamlined Process Automation

>> Data-Driven Quality Control

● Key Components of Smart Control Systems in Powder Coating

>> Sensors and Actuators

>> Programmable Logic Controllers (PLC)

>> Human-Machine Interface (HMI)

>> Software Platforms

● Real-World Benefits of Implementing Smart Control Systems

>> Increased Throughput and Reduced Cycle Times

>> Cost Savings on Materials and Energy

>> Enhanced Product Quality and Consistency

>> Improved Traceability and Reporting

● Future Trends in Smart Powder Coating Control Systems

● Frequently Asked Questions (FAQs)

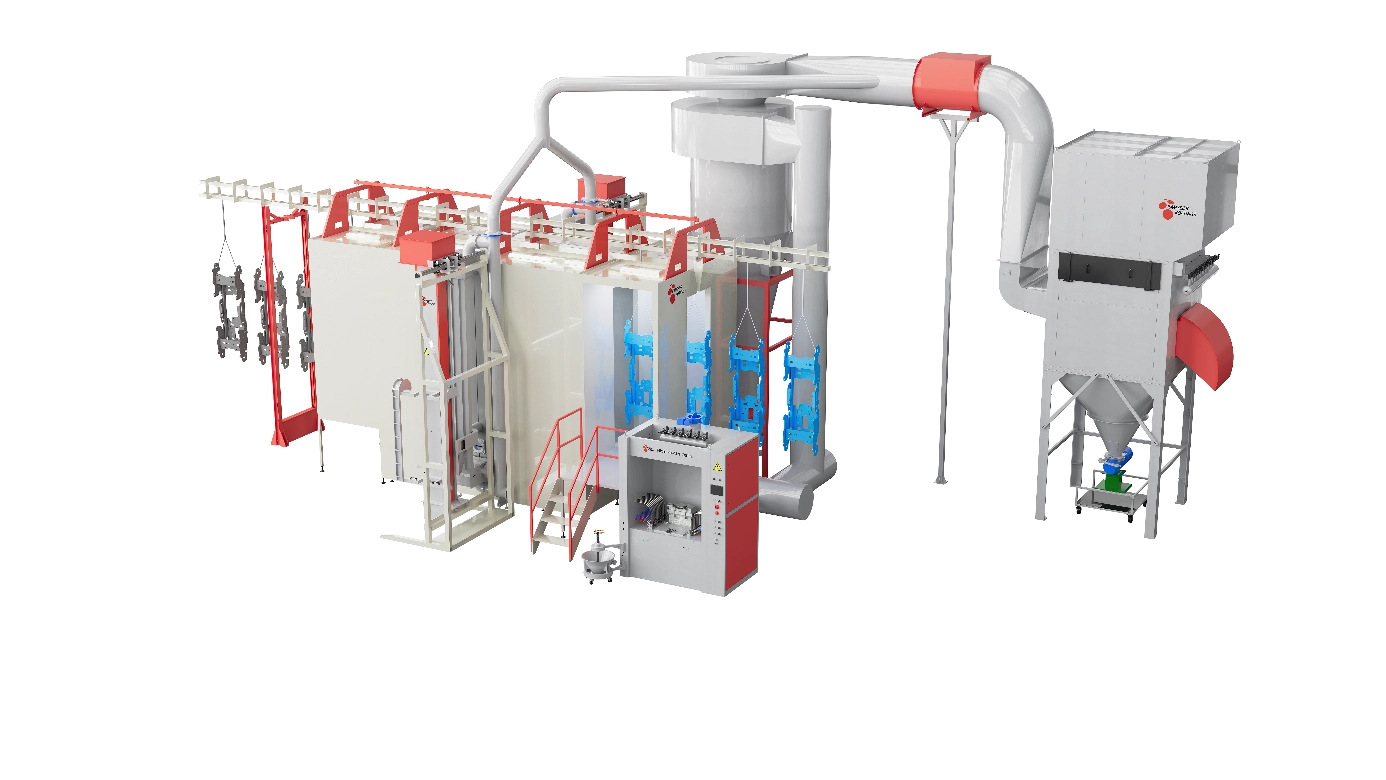

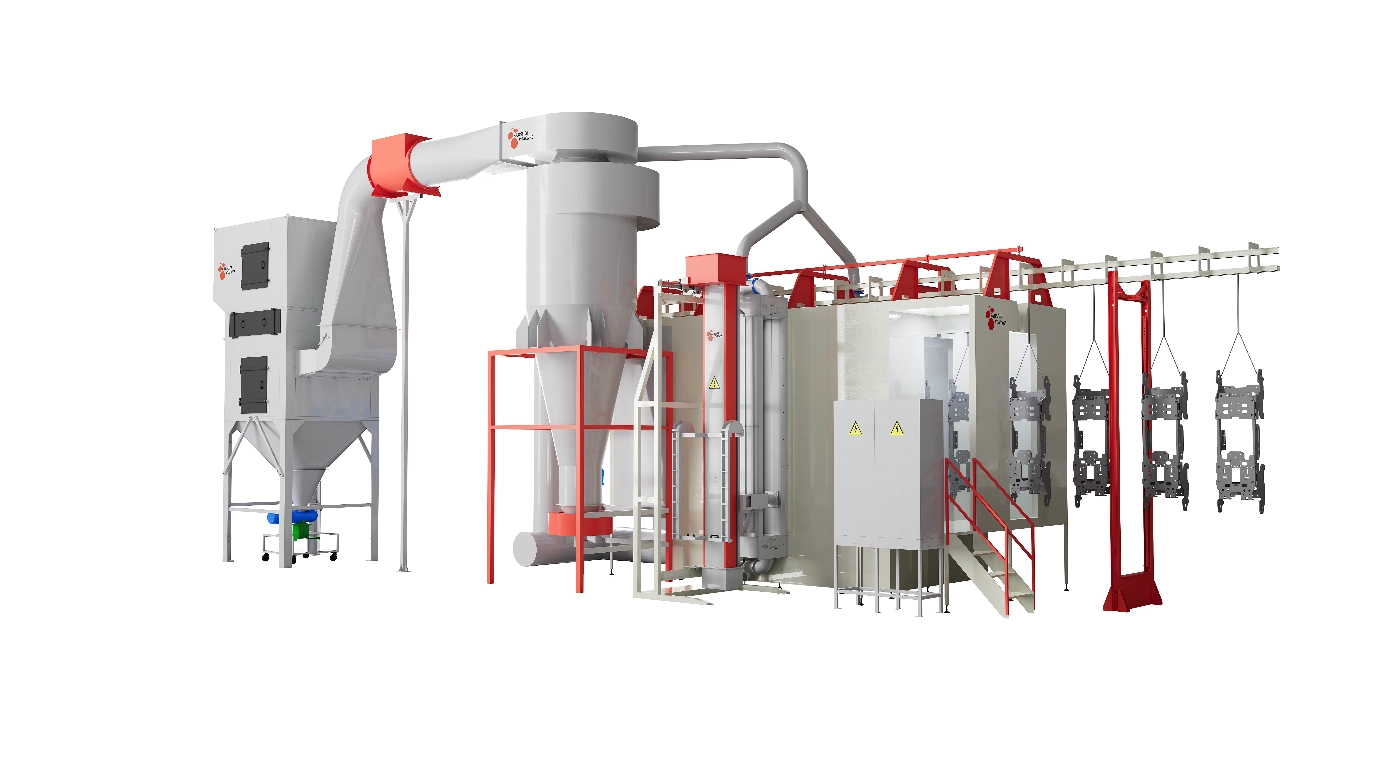

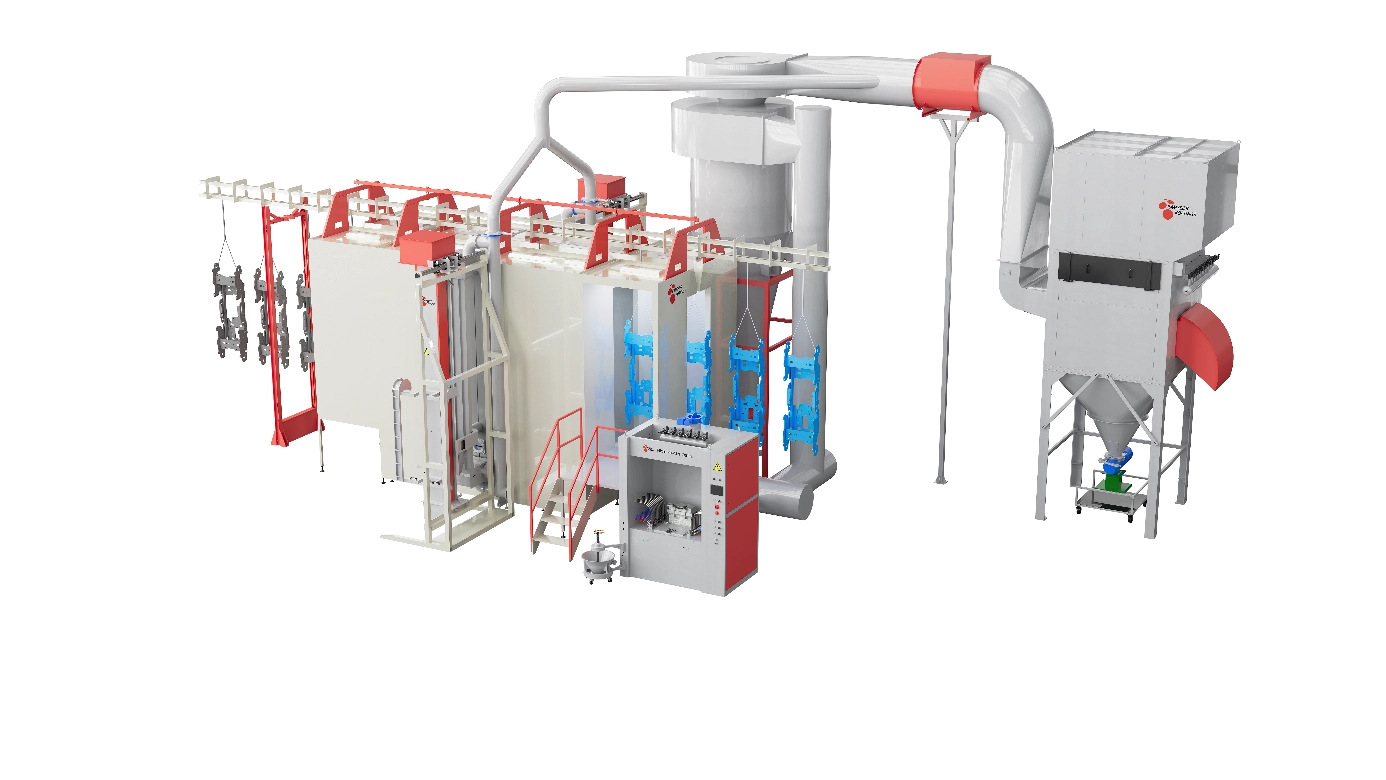

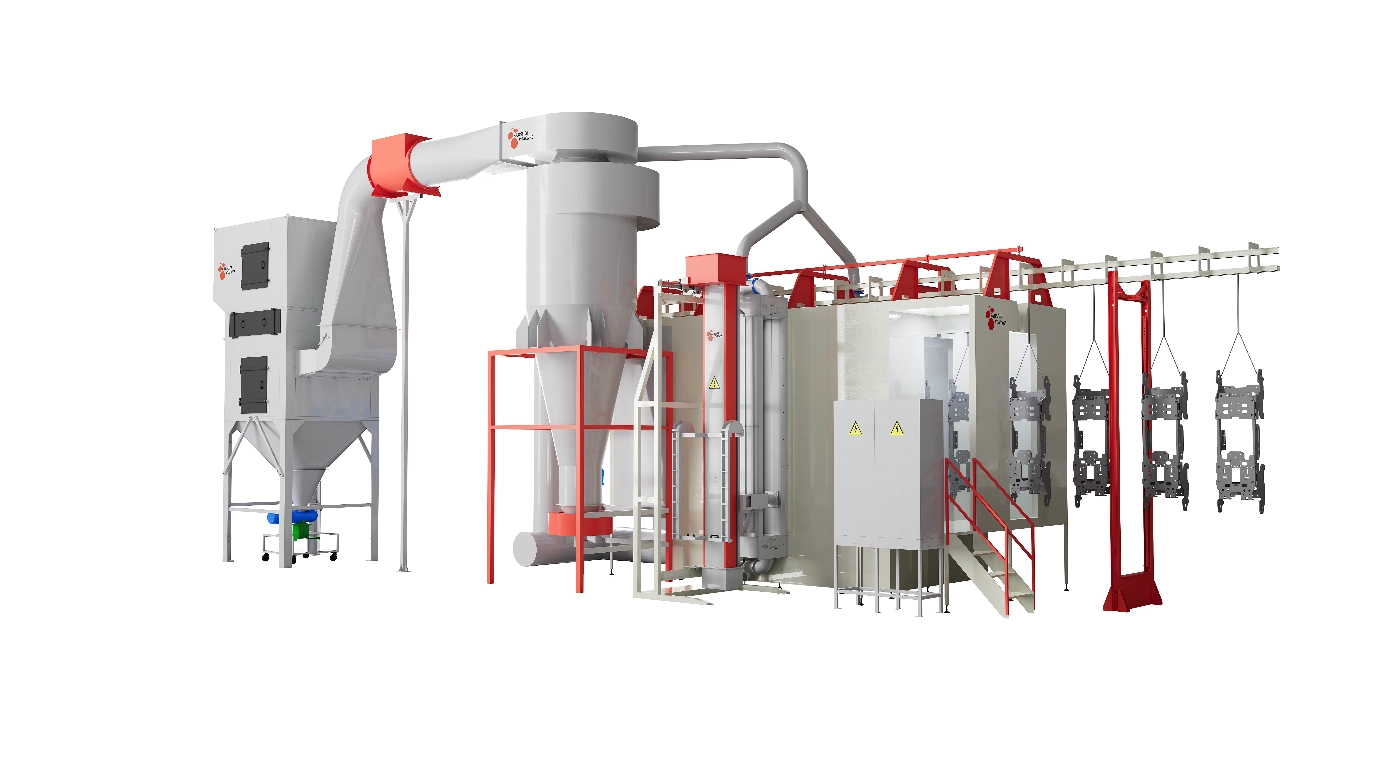

Powder coating is a popular finishing technique widely used across various industries due to its durability, environmental friendliness, and attractive finish. However, achieving high productivity while maintaining quality can be challenging. Smart control systems have emerged as game-changers in powder coating operations, enhancing efficiency, reducing waste, and ensuring consistency. This article explores how smart control systems transform powder coating workflows, significantly boosting productivity.

Understanding Powder Coating and Its Challenges

Powder coating involves applying dry powder electrostatically to a metal surface and then curing it under heat to form a hard, protective layer. While effective, this process faces several challenges:

- Inconsistent coating thickness can lead to quality issues.

- Material waste from overspray and improper application increases costs.

- Manual oversight often limits productivity and repeatability.

- Energy consumption during curing adds to operational expenses.

To overcome these, manufacturers are turning to smart control systems designed to automate, monitor, and optimize powder coating processes.

What Are Smart Control Systems?

Smart control systems in powder coating are integrated technology solutions combining sensors, automation, data analytics, and real-time monitoring to manage the entire coating process more effectively. These systems connect hardware and software to provide precise control over equipment, coating parameters, and workflow sequences.

How Smart Control Systems Enhance Powder Coating Productivity

Precise and Consistent Application

Smart control systems utilize advanced sensors to monitor spray guns, powder flow, and surface conditions. This guarantees that the coating is applied uniformly, preventing areas with too little or too much powder. Consistency in application reduces rework and improves throughput.

- Automated adjustment of spray parameters based on real-time feedback.

- Prevention of coating defects caused by operator error.

- Optimization of powder consumption by precise dosing.

Efficient Material Management

Powder is an expensive input, and its wastage directly impacts profitability. Smart control solutions track powder usage in real-time to minimize overspray and reclaim unused powder.

- Automated powder recovery systems work in sync with control modules.

- Monitoring powder coating booth conditions to optimize extraction and powder recycling.

- Alerts in case of abnormal powder consumption for immediate action.

Streamlined Process Automation

Automation of key processes such as conveyor speed, spray gun positioning, and curing oven temperature ensures smooth workflow and reduces manual labor. Smart control systems enable seamless communication between different coating line components.

- Synchronization of equipment reduces bottlenecks and idle times.

- Programmable recipes for various product types speed up changeovers.

- Remote control and diagnostics reduce downtime due to maintenance.

Data-Driven Quality Control

Data collection enabled by sensors in smart control systems allows for detailed analysis of each coating run. Operators can track parameters like coating thickness, temperature profiles, and cycle times to identify areas for improvement.

- Real-time dashboards provide instant quality feedback.

- Historical data helps in predictive maintenance and process optimization.

- Automated compliance with customer specifications and industry standards.

Key Components of Smart Control Systems in Powder Coating

Sensors and Actuators

Sensors gather critical data such as spray gun position, powder flow rate, humidity, and temperature. Actuators then adjust equipment settings based on this data to maintain optimal conditions.

Programmable Logic Controllers (PLC)

PLCs serve as the system's brain, interpreting sensor input and executing control commands. They coordinate all equipment actions, enabling accurate, automated process control.

Human-Machine Interface (HMI)

The HMI allows operators to interact with the system, monitor operation status, and modify parameters as needed. Modern HMIs often feature touchscreens and intuitive graphics.

Software Platforms

The software integrates all hardware components, providing data analytics, recipe management, remote monitoring, and reporting functionalities.

Real-World Benefits of Implementing Smart Control Systems

Increased Throughput and Reduced Cycle Times

Automation and precise control shorten process times, allowing more products to be coated within the same production window.

Cost Savings on Materials and Energy

Accurate powder dosing and optimized curing reduce material waste and energy use, cutting operational expenses.

Enhanced Product Quality and Consistency

Consistent coating application decreases customer complaints and improves brand reputation.

Improved Traceability and Reporting

Detailed data logs facilitate quality audits, regulatory compliance, and continuous process improvements.

Future Trends in Smart Powder Coating Control Systems

- Artificial Intelligence (AI) integration for predictive quality control and automatic process adjustments.

- Internet of Things (IoT) connectivity enabling fleet-wide management of multiple coating lines.

- Augmented Reality (AR) for remote diagnostics and training.

- Energy-efficient control algorithms to further reduce operational costs.

Frequently Asked Questions (FAQs)

1. How do smart control systems reduce powder wastage?

They use real-time monitoring to adjust spray parameters and optimize booth conditions, minimizing overspray and capturing excess powder for reuse.

2. Can smart control systems be retrofitted to existing powder coating lines?

Yes, many systems are designed for easy integration with legacy equipment to enhance productivity without full line replacement.

3. What role does automation play in powder coating efficiency?

Automation reduces manual errors, speeds up operation cycles, synchronizes equipment, and allows for programming multiple product recipes for faster changeovers.

4. How does data analytics improve powder coating quality?

By analyzing coating thickness, curing temperatures, and other parameters, operators can detect deviations early and implement corrective actions promptly.

5. Are smart control systems cost-effective for small coating shops?

Though initial investment may be higher, the long-term savings in material costs, reduced rework, and increased throughput make them a wise investment even for smaller operations.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.