Content Menu

● Understanding Electrostatic Spray Gun Technology

>> What is an Automatic Electrostatic Spray Gun?

>> Basic Working Principle

● Key Innovations in Automatic Electrostatic Spray Guns

>> Advanced High-Voltage Power Supplies

>> Integration of Smart Sensors and IoT

>> Enhanced Nozzle Designs for Superior Atomization

● Improved Materials and Coating Compatibility

>> Broadening the Range of Coatable Materials

>> Environmentally Friendly Coatings and Reduced Waste

● Automation and Robotics Integration

>> Precision Motion and Position Control

>> Adaptive Spraying Techniques

● Safety Enhancements

>> Improved Electrical Insulation and Arc Prevention

>> User-Friendly Interfaces and Maintenance Alerts

● Future Trends in Electrostatic Spray Gun Technology

>> Integration of Artificial Intelligence (AI)

>> Use of Renewable Energy and Sustainable Practices

>> Miniaturization and Portability

● Frequently Asked Questions (FAQs)

>> 1. What advantages do automatic electrostatic spray guns offer over conventional spray guns?

>> 2. Can electrostatic spray guns be used with water-based paints?

>> 3. How does automation improve the coating process?

>> 4. Are these spray guns safe to use in all environments?

>> 5. What kind of maintenance do automatic electrostatic spray guns require?

Automatic electrostatic spray gun technology has undergone significant advancements in recent years, revolutionizing how industries apply coatings efficiently and sustainably. These innovations improve transfer efficiency, reduce waste, enhance finish quality, and expand the applications of electrostatic spraying across various sectors such as automotive, aerospace, electronics, and industrial manufacturing.

This article explores the latest breakthroughs in automatic electrostatic spray gun technology, outlining cutting-edge features, improved design elements, enhanced control systems, and future trends shaping the industry.

Understanding Electrostatic Spray Gun Technology

What is an Automatic Electrostatic Spray Gun?

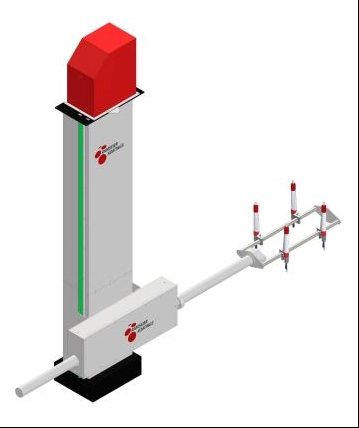

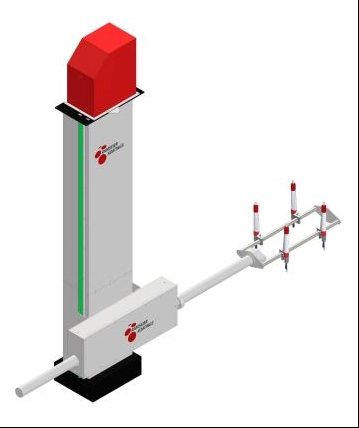

An automatic electrostatic spray gun is a device that charges paint or coating particles electrically before spraying them onto the target surface. This charging causes the droplets to be attracted to the grounded object, improving coating coverage and reducing overspray. The “automatic” aspect refers to the gun's integration in robotic or mechanized systems for consistent, high-speed application without manual intervention.

Basic Working Principle

The spray gun atomizes the coating fluid into fine droplets using air or hydraulic pressure. Simultaneously, the droplets acquire a high-voltage electrical charge. The target surface, being grounded or oppositely charged, attracts the charged particles, resulting in a highly efficient, even coating with minimal waste.

Key Innovations in Automatic Electrostatic Spray Guns

Advanced High-Voltage Power Supplies

Recent developments focus on delivering stable and adjustable high-voltage power supplies to optimize the charging of coating particles. Advanced power converters and microprocessor-controlled units ensure consistent voltage regardless of environmental variations or material types. This leads to better droplet adherence and minimizes electrical arcing risks.

Integration of Smart Sensors and IoT

Modern electrostatic spray guns incorporate smart sensors that can monitor multiple parameters such as spray rate, droplet charge, temperature, and humidity in real time. Connected to IoT platforms, these guns provide operators and automated systems with data analytics for optimizing spray conditions, predictive maintenance, and remote control capabilities, enhancing efficiency and reducing downtime.

Enhanced Nozzle Designs for Superior Atomization

Innovations in nozzle shape and materials have allowed better atomization of coatings, resulting in finer droplets and a more uniform spray pattern. New ceramic and tungsten-carbide nozzles resist wear and corrosion, prolonging service life and maintaining spray quality. Some designs include adjustable spray widths and patterns controlled electronically for different application needs.

Improved Materials and Coating Compatibility

Broadening the Range of Coatable Materials

Developments in material compatibility enable these spray guns to handle a wider variety of coatings, including waterborne, high-viscosity, and abrasive paints. Improved sealing and fluid pathway designs prevent clogging and maintain consistent flow, which is crucial for maintaining coating quality.

Environmentally Friendly Coatings and Reduced Waste

The ability to efficiently apply water-based and low-VOC (volatile organic compound) coatings strengthens the role of electrostatic spray technology in meeting environmental regulations. Innovations decrease paint consumption by maximizing transfer efficiency, significantly reducing emissions and cleaning solvent use.

Automation and Robotics Integration

Precision Motion and Position Control

The coupling of electrostatic spray guns with robotic arms and automated conveyors has become more sophisticated. Enhanced motion control systems featuring laser guidance and vision-based feedback ensure consistent coverage over complex 3D surfaces, reducing the need for rework.

Adaptive Spraying Techniques

New automatic spray systems can dynamically adjust spray parameters based on real-time feedback about surface geometry, coating thickness, and environmental conditions. This adaptability prevents defects such as runs or sags, ensuring a smooth, durable finish every time.

Safety Enhancements

Improved Electrical Insulation and Arc Prevention

To reduce the hazards inherent in working with high voltages, manufacturers have introduced comprehensive insulation improvements and arc detection circuits. These features protect operators and equipment, particularly in high-humidity or wet environments, extending the usable conditions for electrostatic spray guns.

User-Friendly Interfaces and Maintenance Alerts

Touchscreen controls and intuitive software simplify the setup and operation of automatic electrostatic guns. Alerts and diagnostic tools notify operators in advance about maintenance needs or performance issues, avoiding unexpected equipment failures.

Future Trends in Electrostatic Spray Gun Technology

Integration of Artificial Intelligence (AI)

AI-driven systems are anticipated to further optimize spray parameters by learning from operational data to predict failures, adjust spray patterns, and enhance coating quality autonomously.

Use of Renewable Energy and Sustainable Practices

As sustainability becomes paramount, integrating electrostatic spray guns with renewable energy sources and eco-friendly processes will reduce the carbon footprint of coating operations.

Miniaturization and Portability

New materials and electronic advancements will enable smaller, lightweight electrostatic spray guns suitable for field applications or small-scale manufacturing environments previously unsuitable for electrostatic coating.

Frequently Asked Questions (FAQs)

1. What advantages do automatic electrostatic spray guns offer over conventional spray guns?

Automatic electrostatic spray guns provide higher transfer efficiency, reduced paint waste, uniform coating, and better surface adhesion. Because of charged particles, coatings better wrap around complex shapes, reducing overspray and environmental pollution.

2. Can electrostatic spray guns be used with water-based paints?

Yes. Recent innovations allow electrostatic spray guns to apply waterborne coatings effectively, making the process more environmentally friendly and compliant with modern emission standards.

3. How does automation improve the coating process?

Automation increases repeatability and precision, minimizing human error and achieving consistent high-quality finishes. Robots with electrostatic guns can cover large or intricate surfaces quickly with minimal downtime.

4. Are these spray guns safe to use in all environments?

While improved insulation and safety systems have enhanced usability, extreme wet or explosive environments require specialized equipment or precautions. Operators must always follow manufacturer guidelines and safety standards.

5. What kind of maintenance do automatic electrostatic spray guns require?

Regular cleaning, nozzle inspection, and monitoring of electrical components are essential. Modern guns include software to alert users about maintenance needs to prevent failures and ensure optimal operation.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.