Content Menu

● Understanding Electrostatic Spray Gun Technology

>> Principles of Electrostatic Spraying

● The Emergence of Automation in Electrostatic Spraying

>> Types of Automation in Electrostatic Spray Systems

● Advantages of Automation in Electrostatic Spray Gun Technology

>> Increased Precision and Consistency

>> Enhanced Productivity and Throughput

>> Material Savings and Environmental Impact

>> Worker Safety and Ergonomics

● Key Components of Automated Electrostatic Spray Systems

>> Robotic Spray Gun Manipulators

>> Control Software and Interfaces

>> Sensors and Quality Monitoring Systems

● Applications of Automated Electrostatic Spray Gun Technology

>> Automotive Industry

>> Aerospace and Defense

>> Consumer Goods Manufacturing

>> Industrial Equipment and Machinery

● Challenges and Considerations in Implementing Automation

>> Initial Investment Costs

>> System Complexity and Maintenance

>> Flexibility and Adaptability

● Future Trends in Automated Electrostatic Spray Gun Technology

>> Artificial Intelligence and Machine Learning

>> Internet of Things (IoT) Integration

>> Advanced Sensor Technologies

>> Collaborative Robots (Cobots)

● Conclusion

● Frequently Asked Questions (FAQ)

Electrostatic spray gun technology has revolutionized the painting and coating industries by enabling efficient, uniform application of coatings with minimal waste. In recent years, the integration of automation into this technology has further enhanced its effectiveness, productivity, and environmental benefits. This article explores the critical role automation plays in modern electrostatic spray gun systems, examining its advantages, technical advancements, and future potential for various industrial applications.

Understanding Electrostatic Spray Gun Technology

Electrostatic spray guns apply coatings by charging the spray particles as they exit the nozzle, which then are attracted to the grounded workpiece. This electrostatic attraction improves transfer efficiency, reduces overspray, and enhances coating uniformity.

Principles of Electrostatic Spraying

- Charging Mechanism: Spray particles are charged positively or negatively by an internal electrode.

- Attraction to Workpiece: The grounded object attracts oppositely charged particles, improving coverage.

- Particle Size and Spray Pattern: Optimized to ensure consistent coating thickness.

The Emergence of Automation in Electrostatic Spraying

Automation introduces programmable controls, robotics, sensors, and advanced software to electrostatic spray gun operations. This integration allows for precise control and repeatability that manual spraying cannot achieve.

Types of Automation in Electrostatic Spray Systems

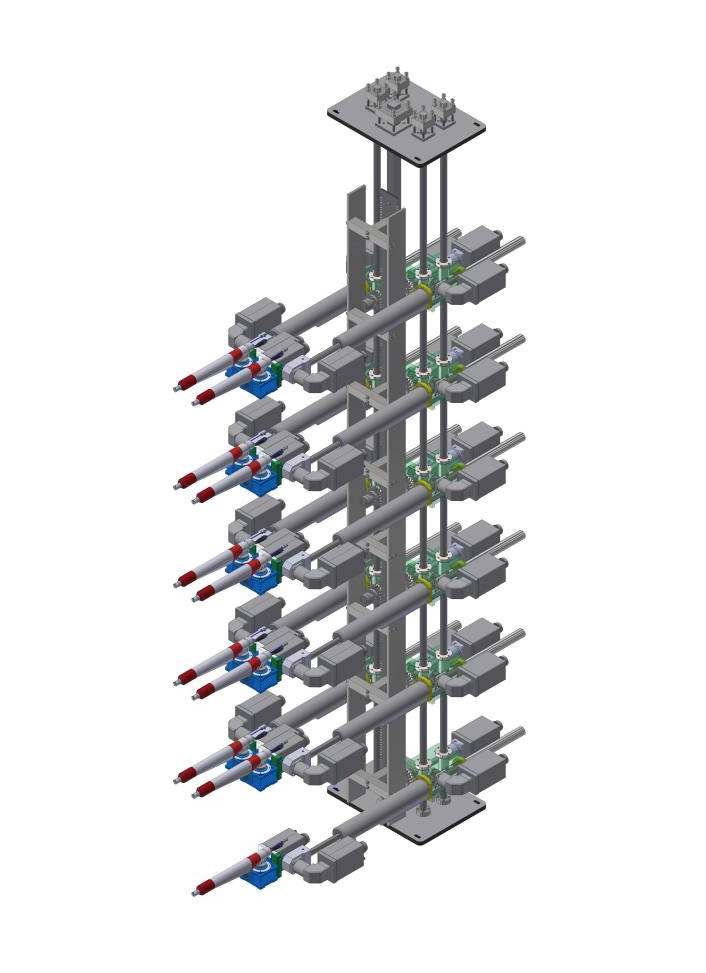

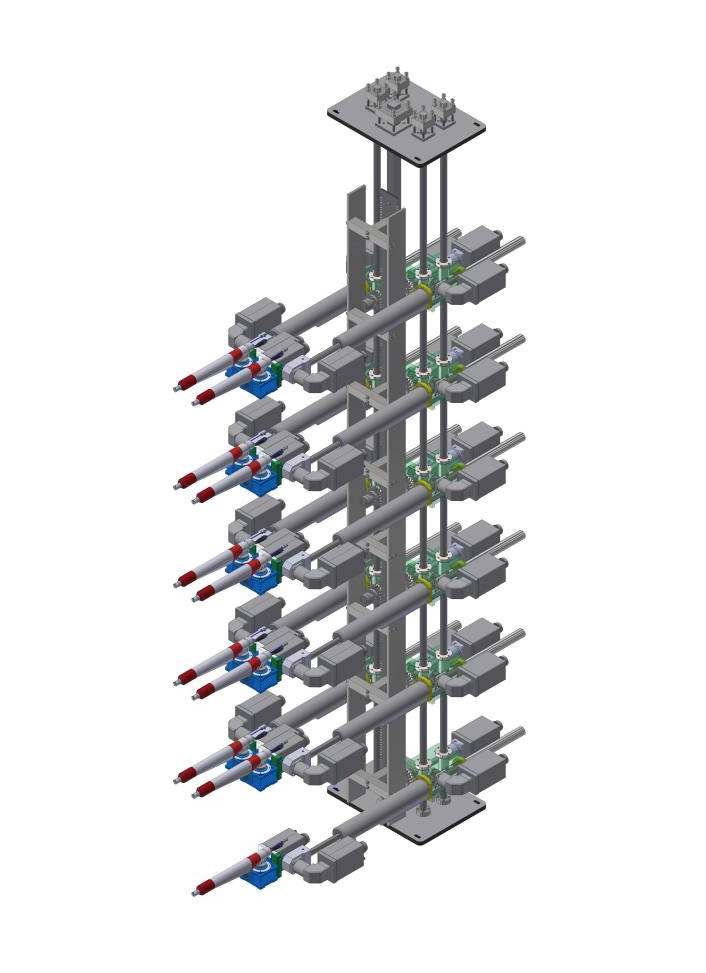

- Robotic Arms: Allow accurate, repeatable spray paths on complex geometries.

- Programmable Logic Controllers (PLC): Manage spray parameters such as voltage, flow rate, and speed programmatically.

- Sensors and Feedback Loops: Monitor spray quality and adjust parameters in real time.

- Automated Material Handling: Coordinate the movement of items through spray booths to optimize throughput.

Advantages of Automation in Electrostatic Spray Gun Technology

Automation uplifts productivity, consistency, and safety in electrostatic coating processes while conserving materials.

Increased Precision and Consistency

Automated systems maintain exact spray distances, angles, and speeds, ensuring uniform coatings devoid of human error variability.

Enhanced Productivity and Throughput

Robots operate continuously with minimal downtime, speeding up the coating process and enabling 24/7 production capability.

Material Savings and Environmental Impact

Optimized transfer efficiency reduces paint consumption and volatile organic compound (VOC) emissions, aligning with green manufacturing practices.

Worker Safety and Ergonomics

Automation reduces worker exposure to hazardous fumes and repetitive strain injuries by replacing manual spraying in challenging environments.

Key Components of Automated Electrostatic Spray Systems

Successful integration requires advanced hardware and software components designed for precision control and robust performance.

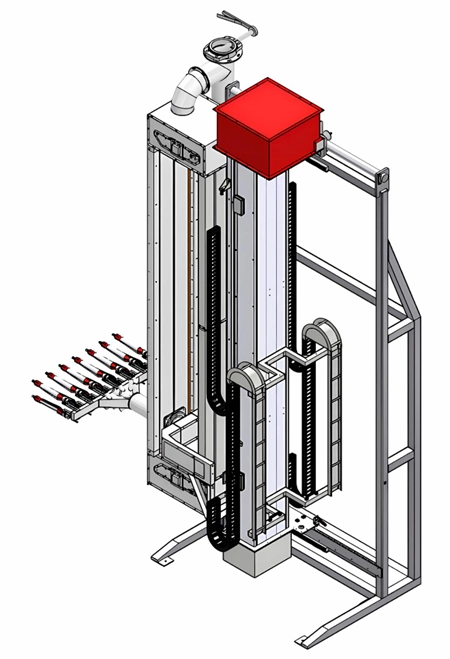

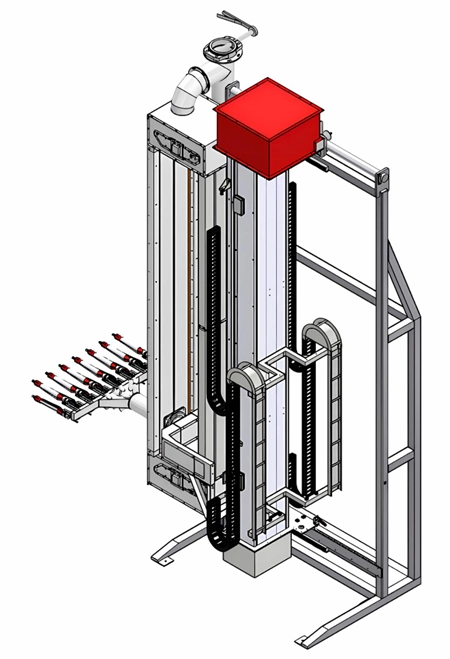

Robotic Spray Gun Manipulators

Robotic arms equipped with electrostatic spray guns perform programmed motion trajectories adapted to the geometry and size of the target.

Control Software and Interfaces

User-friendly software enables paint shops to design spray patterns, adjust voltages, and monitor system health through graphical user interfaces and remote diagnostics.

Sensors and Quality Monitoring Systems

Vision systems and particle sensors assess spray uniformity and correct anomalies during the spraying process, enhancing coating quality.

Applications of Automated Electrostatic Spray Gun Technology

Automation has broadened the application scope of electrostatic spraying across multiple industries, improving outcomes and lowering costs.

Automotive Industry

High-precision automation coats vehicle bodies and parts with improved finish quality and minimized paint waste.

Aerospace and Defense

Complex components receive uniform protection coatings essential for durability under extreme conditions.

Consumer Goods Manufacturing

Mass production of appliances and electronics benefits from faster spray cycles and consistent surface finishes.

Industrial Equipment and Machinery

Tough industrial coatings on heavy equipment are applied more efficiently, extending service life.

Challenges and Considerations in Implementing Automation

While automation offers numerous benefits, its adoption requires overcoming certain challenges.

Initial Investment Costs

High upfront capital investment in robotics and control systems can be a barrier for small and medium enterprises.

System Complexity and Maintenance

Automated systems require specialized technical expertise for programming, calibration, and upkeep.

Flexibility and Adaptability

Adapting to new product lines or design changes may require reprogramming and hardware adjustments.

Future Trends in Automated Electrostatic Spray Gun Technology

Emerging technologies promise to further refine and expand automation capabilities in electrostatic spraying.

Artificial Intelligence and Machine Learning

AI algorithms can optimize spray parameters dynamically based on real-time feedback to improve quality and efficiency.

Internet of Things (IoT) Integration

IoT connectivity enables remote monitoring, predictive maintenance, and data-driven decision-making.

Advanced Sensor Technologies

New sensors provide higher-resolution data on coating thickness and environmental conditions.

Collaborative Robots (Cobots)

Cobots work safely alongside human operators, combining automation benefits with human adaptability.

Conclusion

Automation has fundamentally transformed modern electrostatic spray gun technology by increasing precision, efficiency, and sustainability. From robotic sprayers and advanced control software to sensor-driven feedback systems, automation enhances coating process reliability while reducing costs and environmental impact. As innovations continue with AI and IoT integration, the future of electrostatic spraying lies in increasingly intelligent, flexible, and user-friendly automated systems tailored to diverse industrial needs.

Frequently Asked Questions (FAQ)

1. What is the primary benefit of automation in electrostatic spray gun technology?

Automation provides consistent coating quality, increased productivity, and reduced material waste by precisely controlling spray parameters.

2. How do robotic arms improve the electrostatic spraying process?

Robotic arms execute exact, repeatable spray patterns that optimize coverage and reduce human error, especially on complex-shaped objects.

3. Can automated electrostatic spray guns reduce environmental impact?

Yes, by improving transfer efficiency and minimizing overspray, automation reduces paint consumption and volatile emissions.

4. What industries benefit most from automated electrostatic spraying?

Automotive, aerospace, consumer goods, and heavy machinery industries benefit greatly due to high demands for uniform coatings and efficiency.

5. What challenges might companies face when implementing automated electrostatic spray systems?

Challenges include high initial costs, system complexity requiring technical expertise, and limited flexibility for product design changes without reprogramming.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.