Content Menu

● Understanding Electrostatic Spray Guns

>> What Is an Electrostatic Spray Gun?

>> Advantages Over Conventional Spray Guns

● Key Factors to Consider When Choosing an Automatic Electrostatic Spray Gun

>> 1. Application Requirements

>>> Type of Coating Material

>>> Substrate Material

>>> Surface Geometry

>> 2. Spray Gun Type and Features

>>> Automatic vs. Manual

>>> Power Source

>>> Tank Capacity and Material Delivery

>>> Nozzle and Spray Pattern

>> 3. Efficiency and Cost Considerations

>>> Transfer Efficiency and Paint Savings

>>> Maintenance and Durability

>>> Environmental and Regulatory Compliance

● How to Overcome Common Challenges

>> Managing the Faraday Cage Effect

>> Handling Different Coating Types

● Steps to Select the Right Electrostatic Spray Gun for Your Business

● Frequently Asked Questions

>> 1. What industries benefit most from electrostatic spray guns?

>> 2. Can electrostatic spray guns be used on plastic or wood surfaces?

>> 3. How does the Faraday cage effect impact spraying?

>> 4. Are automatic electrostatic spray guns expensive?

>> 5. What maintenance is required for electrostatic spray guns?

Electrostatic spray guns have revolutionized the coating and painting industries by offering superior efficiency, reduced waste, and high-quality finishes. Selecting the right automatic electrostatic spray gun for your business is crucial to maximize productivity, reduce costs, and achieve consistent results. This comprehensive guide will walk you through the essential factors to consider when choosing an electrostatic spray gun tailored to your specific business needs.

Understanding Electrostatic Spray Guns

What Is an Electrostatic Spray Gun?

An electrostatic spray gun uses high-voltage electrostatic charges to atomize and direct paint or coating particles toward a grounded target surface. The charged particles are attracted to the surface, which enhances coverage and reduces overspray. This technology is widely used in industries such as automotive, furniture, hardware, and agricultural applications due to its efficiency and environmental benefits.

Advantages Over Conventional Spray Guns

- Higher Transfer Efficiency: Electrostatic spray guns can achieve up to 95% transfer efficiency, meaning more paint adheres to the target and less is wasted.

- Improved Coverage: The electrostatic charge causes paint particles to wrap around complex shapes, ensuring even coating on hard-to-reach areas.

- Cost and Material Savings: Reduced overspray leads to significant savings in paint and labor.

- Environmental Benefits: Less paint waste means fewer volatile organic compounds (VOCs) released into the environment.

- Health and Safety: Lower paint mist in the air improves worker safety and reduces cleanup time.

Key Factors to Consider When Choosing an Automatic Electrostatic Spray Gun

1. Application Requirements

Type of Coating Material

Different coatings such as solvent-based, waterborne, or powder coatings have varying viscosities and electrical properties. Some electrostatic guns require conductive primers or special settings to optimize coating adhesion, especially when spraying non-conductive materials like plastics or wood.

Substrate Material

The substrate must be conductive or grounded to attract the charged particles effectively. For non-conductive substrates, additional preparation or conductive primers may be necessary.

Surface Geometry

Complex shapes with recesses or corners may experience the Faraday cage effect, where electrostatic charges repel paint from recessed areas. In such cases, combining electrostatic spraying with conventional methods or adjusting voltage and air pressure can improve coverage.

2. Spray Gun Type and Features

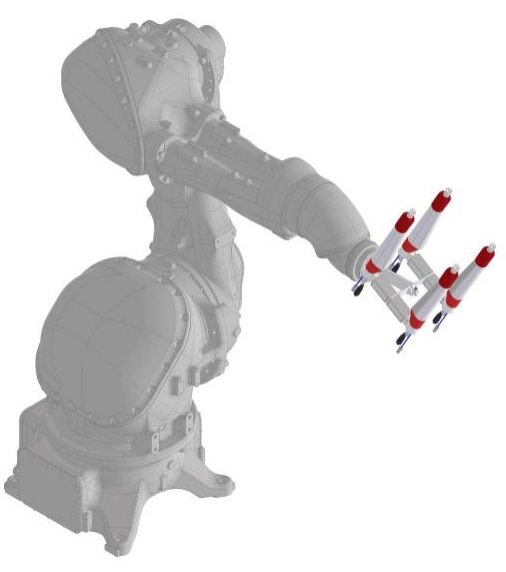

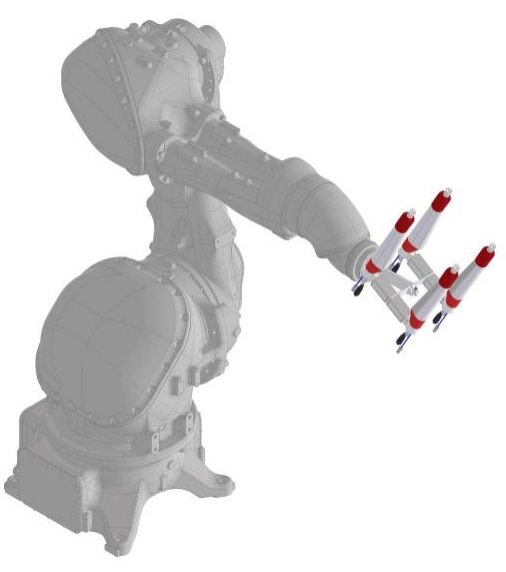

Automatic vs. Manual

Automatic electrostatic spray guns are integrated into production lines or robotic systems, offering consistent application and high throughput. Manual guns provide flexibility for smaller or irregular jobs but may have lower efficiency.

Power Source

Options include pneumatic, battery-operated, or electric-powered guns. Battery-powered units offer portability and ease of use, while electric models provide continuous power for large-scale operations.

Tank Capacity and Material Delivery

Consider the volume of paint or coating to be applied per cycle. Larger tanks and efficient fluid delivery systems reduce downtime and improve productivity.

Nozzle and Spray Pattern

Adjustable nozzles and spray patterns allow customization for different coating thicknesses and surface types. Proper nozzle selection is critical for achieving the desired finish quality.

3. Efficiency and Cost Considerations

Transfer Efficiency and Paint Savings

Higher transfer efficiency directly translates to material savings. Although electrostatic guns may have a higher upfront cost compared to conventional spray guns, the reduction in paint waste and labor costs results in a strong return on investment.

Maintenance and Durability

Look for guns made with robust materials that withstand harsh chemicals and frequent use. Easy-to-clean designs reduce maintenance time and prolong equipment life.

Environmental and Regulatory Compliance

Electrostatic spray guns help meet environmental regulations by minimizing VOC emissions and paint waste, making them a sustainable choice for businesses.

How to Overcome Common Challenges

Managing the Faraday Cage Effect

The Faraday cage effect can cause uneven coating on recessed or shadowed areas. To mitigate this:

- Use a combination of electrostatic and conventional spray guns.

- Adjust electrostatic voltage and air pressure to direct paint into corners.

- Employ robotic arms or multi-axis sprayers to reach difficult angles.

Handling Different Coating Types

Waterborne coatings may require additional equipment such as isolation systems or external charging applicators to work effectively with electrostatic guns. Verify compatibility with your coating materials before purchase.

Steps to Select the Right Electrostatic Spray Gun for Your Business

1. Assess Your Application Needs: Identify the type of coatings, substrates, and production scale.

2. Evaluate Equipment Features: Consider automatic vs. manual operation, power source, tank size, and nozzle options.

3. Calculate Total Cost of Ownership: Include initial cost, maintenance, paint savings, and labor efficiency.

4. Consult Experts and Manufacturers: Leverage technical support for matching equipment to your specific requirements.

5. Test and Fine-Tune: Trial runs help optimize settings for best performance and finish quality.

Frequently Asked Questions

1. What industries benefit most from electrostatic spray guns?

Industries such as automotive manufacturing, furniture production, hardware coating, agricultural spraying, and electronics benefit significantly due to improved efficiency and finish quality.

2. Can electrostatic spray guns be used on plastic or wood surfaces?

Yes, but often a conductive primer or special preparation is required to ensure proper charge attraction and coating adhesion.

3. How does the Faraday cage effect impact spraying?

It causes paint to accumulate on edges rather than recessed areas, which can be mitigated by adjusting voltage, using conventional spray guns for those areas, or employing robotic sprayers.

4. Are automatic electrostatic spray guns expensive?

They generally have a higher upfront cost than conventional guns but offer substantial savings on paint, labor, and environmental compliance, resulting in a strong return on investment.

5. What maintenance is required for electrostatic spray guns?

Regular cleaning, inspection of nozzles and electrodes, and ensuring proper grounding are essential to maintain performance and longevity.

[1] https://roboticpaint.com/electrostatic-spray-gun-guide/

[2] https://www.alibaba.com/showroom/electrostatic-spray-gun-price.html

[3] https://www.graco.com/us/en/in-plant-manufacturing/solutions/articles/conventional-vs-electrostatic-spray-guns.html

[4] https://patents.google.com/patent/WO2022027736A1/en

[5] https://www.durr.com/fileadmin/durr.com/09_MISC/19_Digital_Press_Kit/duerr-spraygunselectionguide.pdf

[6] https://patents.google.com/patent/CN101351273B/en

[7] https://www.sprayequipment.com/blog/guide-to-buying-a-spray-gun-with-spray-equipment-service-center

[8] https://patents.google.com/patent/CN101184555B/zh

[9] https://www.codinter.com/en/automatic-spray-guns-a-complete-guide/

[10] https://patents.google.com/patent/CN101014415A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.