Content Menu

● Understanding Automatic Electrostatic Spray Guns

>> Components of an Automatic Electrostatic Spray Gun

● Common Problems and Their Solutions

>> 1. Inconsistent Spray Pattern

>>> Possible Causes

>>> Troubleshooting Steps

>> 2. Low Transfer Efficiency

>>> Possible Causes

>>> Troubleshooting Steps

>> 3. Paint Spitting or Sputtering

>>> Possible Causes

>>> Troubleshooting Steps

>> 4. Electrostatic Charge Issues

>>> Possible Causes

>>> Troubleshooting Steps

>> 5. Irregular Fluid Flow Rate

>>> Possible Causes

>>> Troubleshooting Steps

● Preventive Maintenance for Optimal Performance

>> Cleaning Routine

>> Inspection and Replacement Schedule

>> Environmental Controls

● Advanced Troubleshooting Tips

>> Using Diagnostic Tools

>> Software and Control System Checks

● Frequently Asked Questions (FAQ)

>> 1. Why is my spray gun producing uneven coats despite regular cleaning?

>> 2. How often should I replace the nozzle on an automatic electrostatic spray gun?

>> 3. Can environmental humidity affect electrostatic spray performance?

>> 4. What causes paint spitting in electrostatic spray guns, and how do I fix it?

>> 5. How critical is grounding when using an electrostatic spray gun?

Automatic electrostatic spray guns are widely used in industries ranging from automotive to electronics for their efficiency in applying coatings with precision and reduced waste. However, like any sophisticated equipment, these spray guns can encounter operational issues that affect performance and output quality. Understanding the common problems and how to troubleshoot them effectively can save time, reduce costs, and maintain product quality.

This comprehensive guide covers typical issues with automatic electrostatic spray guns, troubleshooting steps, and maintenance tips to keep your equipment operating smoothly.

Understanding Automatic Electrostatic Spray Guns

Before diving into troubleshooting, it's important to understand how automatic electrostatic spray guns operate. These devices use an electrical charge to atomize paint or coating materials and direct them toward the target surface with improved transfer efficiency. The electrical charge causes the paint particles to repel each other and adhere more uniformly, reducing overspray and waste.

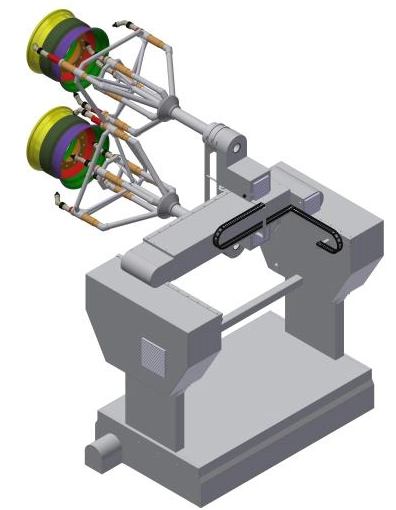

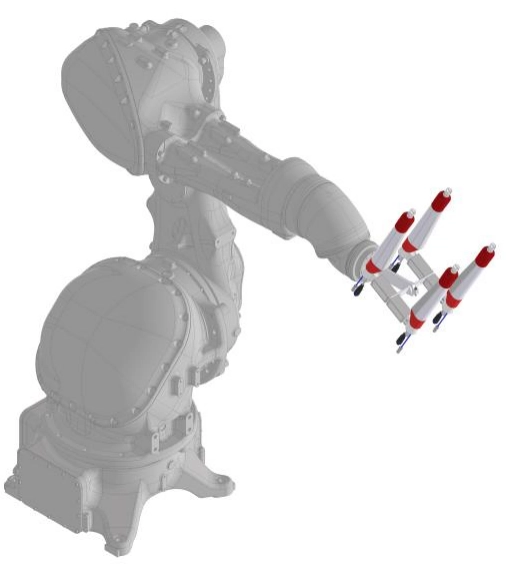

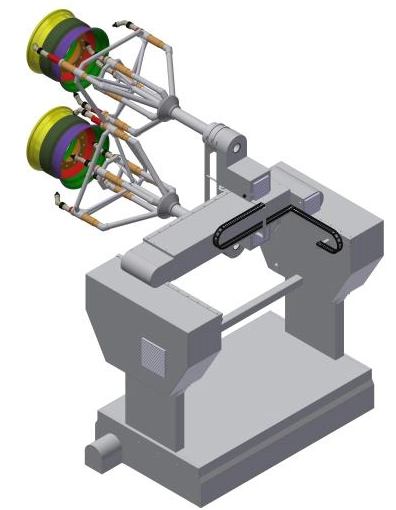

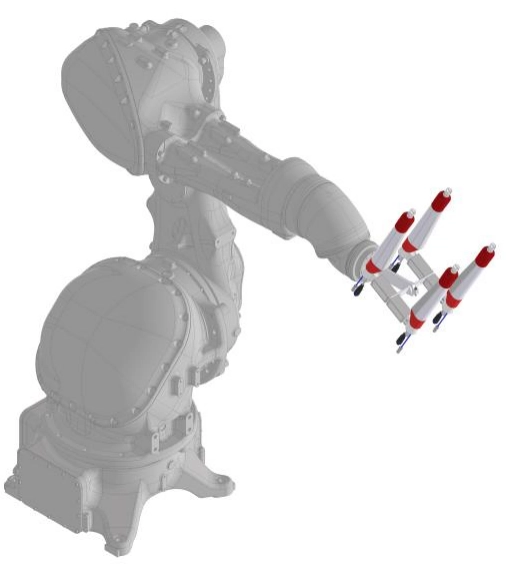

Components of an Automatic Electrostatic Spray Gun

- Electrostatic generator: Produces the high voltage needed for charging paint particles.

- Nozzle: Atomizes the paint material.

- Air supply system: Provides compressed air for atomization and fan shaping.

- Control system: Automates the spray process and adjusts parameters.

- Fluid supply: Delivers paint or coating material to the nozzle.

Now, let's explore the common issues users face and how to resolve them.

Common Problems and Their Solutions

1. Inconsistent Spray Pattern

An irregular or inconsistent spray pattern can cause uneven coating, leading to defective products.

Possible Causes

- Clogged nozzle or air cap.

- Improper air pressure settings.

- Damaged or worn nozzle.

- Insufficient fluid supply or blockages.

- Incorrect electrostatic charge level.

Troubleshooting Steps

- Clean the nozzle and air cap: Remove any dried paint or debris carefully using recommended cleaning tools and solvents.

- Check air pressure: Ensure that the compressed air supply meets the manufacturer's specified pressure range.

- Inspect the nozzle: Replace the nozzle if it shows signs of wear or damage.

- Verify fluid flow: Confirm the fluid lines are clear and the fluid is consistent.

- Adjust electrostatic settings: Test and calibrate the voltage to the recommended level to ensure proper paint charging.

2. Low Transfer Efficiency

If too much paint misses the target, causing wastage and poor coating, transfer efficiency is likely compromised.

Possible Causes

- Weak or intermittent electrostatic charge.

- Incorrect gun-to-work distance.

- Poor grounding of the workpiece.

- High air pressure causing excessive overspray.

Troubleshooting Steps

- Check the power supply: Ensure the electrostatic generator is functioning properly and outputting a stable charge.

- Optimize distance: Maintain the recommended distance from the gun to the target surface, usually between 6 to 12 inches.

- Verify grounding: Confirm the workpiece is properly grounded to allow charged paint particles to attract effectively.

- Adjust air pressure: Reduce air pressure to minimize overspray and improve particle deposition.

3. Paint Spitting or Sputtering

Paint that spits or sputters from the nozzle results in an uneven finish and material waste.

Possible Causes

- Air trapped in the fluid line.

- Blocked fluid passages.

- Improper fluid viscosity.

- Loose or damaged seals.

Troubleshooting Steps

- Bleed air from the system: Follow manufacturer procedures to purge trapped air in the fluid lines.

- Inspect and clean fluid passages: Remove blockages in passages and filters.

- Check fluid viscosity: Thin or thicken the paint as necessary to meet applicator specs.

- Replace seals: Install new seals to prevent leaks and maintain consistent fluid flow.

4. Electrostatic Charge Issues

If the paint particles are not properly charged, coating adhesion and quality will be negatively impacted.

Possible Causes

- Faulty high-voltage cable or connections.

- Dirty or damaged charging electrode.

- Inadequate power supply.

- Environmental factors like high humidity.

Troubleshooting Steps

- Inspect cables: Look for cracks or wear in cables and connections; replace if necessary.

- Clean electrodes: Carefully remove paint buildup and debris from the charging electrodes.

- Test power output: Use a high-voltage meter to verify the electrostatic generator's output.

- Control environment: Maintain proper humidity levels; very high humidity can reduce charging efficiency.

5. Irregular Fluid Flow Rate

Inconsistent fluid flow results in an uneven coating thickness.

Possible Causes

- Faulty fluid pump.

- Blocked fluid filters.

- Incorrect pump settings.

- Worn or damaged valves.

Troubleshooting Steps

- Examine and clean filters: Regularly clean or replace fluid filters.

- Test pump operation: Ensure the fluid pump delivers a consistent flow rate with no interruptions.

- Adjust pump settings: Calibrate the pump to the required flow rate for your application.

- Replace valves: Worn valves can cause fluctuating fluid flow and should be replaced.

Preventive Maintenance for Optimal Performance

Regular maintenance is key to preventing many of these common issues.

Cleaning Routine

- Clean nozzles, air caps, and electrodes after every use.

- Flush fluid lines with appropriate solvents.

- Wipe down external components to remove overspray.

Inspection and Replacement Schedule

- Inspect hoses and cables routinely for damage.

- Replace seals, filters, and worn parts on schedule.

- Periodically calibrate the electrostatic power supply.

Environmental Controls

- Maintain stable temperature and humidity in the spraying environment.

- Use proper grounding and avoid static buildup on equipment and operators.

Advanced Troubleshooting Tips

Using Diagnostic Tools

- High-voltage meters can help troubleshoot charging issues.

- Pressure gauges verify air and fluid pressures.

- Flow meters ensure consistent fluid delivery.

Software and Control System Checks

Many automatic electrostatic spray guns have control software that can be updated or recalibrated to correct errors.

- Verify firmware is up to date.

- Reset to factory settings if erratic behavior occurs.

- Consult manufacturer support for troubleshooting software-related issues.

Frequently Asked Questions (FAQ)

1. Why is my spray gun producing uneven coats despite regular cleaning?

Uneven coats can result from factors beyond cleanliness, such as improper air pressure, incorrect electrostatic voltage, damaged nozzles, or poor grounding. Recheck all these areas to diagnose the exact cause.

2. How often should I replace the nozzle on an automatic electrostatic spray gun?

Nozzle lifespan varies based on usage and coating material. Generally, replace nozzles after 500 to 1000 hours of use or if you notice wear, damage, or poor spray patterns.

3. Can environmental humidity affect electrostatic spray performance?

Yes, high humidity levels reduce the ability of paint particles to hold an electrostatic charge, decreasing transfer efficiency. Maintain humidity below 60% for optimal performance.

4. What causes paint spitting in electrostatic spray guns, and how do I fix it?

Paint spitting is typically caused by trapped air in fluid lines, blockages, or incorrect viscosity. Bleeding air from the system, cleaning fluid passages, and adjusting paint viscosity usually resolve this issue.

5. How critical is grounding when using an electrostatic spray gun?

Proper grounding is essential as it completes the electrical circuit that attracts charged paint particles to the target. Poor grounding results in low transfer efficiency and overspray.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.