Content Menu

● Understanding Reciprocators in Coating Systems

>> What Is a Reciprocator?

>> Role of Reciprocators in Powder Coating

● Key Factors to Consider When Choosing a Reciprocator

>> 1. Production Line Speed and Throughput

>> 2. Part Size and Geometry

>> 3. Gun Arrangement and Number of Guns

>> 4. Coating Material and Transfer Efficiency

>> 5. Stroke Speed and Dwell Time

>> 6. Load Capacity and Maintenance

● Technical Considerations for Reciprocator Selection

>> H2: Calculating Reciprocator Stroke and Speed

>> H3: Number of Guns Required

>> H3: Minimizing Overspray and Edge Buildup

● Practical Tips for Choosing the Right Reciprocator

>> Align Reciprocator Speed with Conveyor Speed

>> Match Stroke Length to Part Dimensions

>> Consider Coating Material Characteristics

>> Evaluate System Load and Maintenance Needs

>> Test and Validate in Real Conditions

● Advanced Features and Innovations

● Frequently Asked Questions (FAQs)

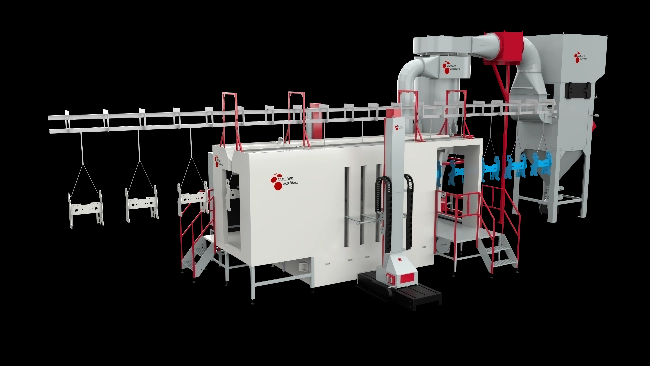

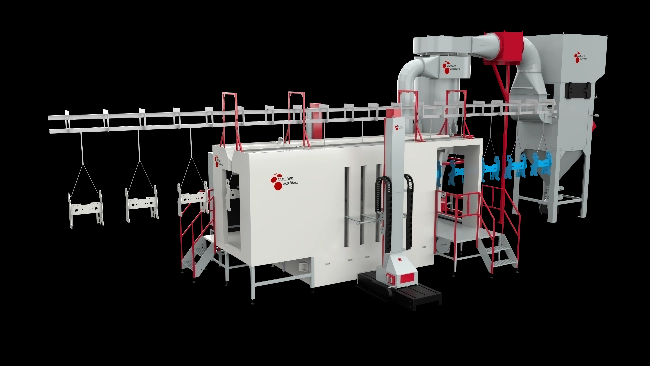

In the powder coating industry, the choice of the right reciprocator is critical to achieving high-quality finishes, operational efficiency, and cost-effectiveness. A reciprocator is a mechanical device that moves spray guns vertically or horizontally to evenly coat parts as they pass through a coating system. Selecting the appropriate reciprocator depends on various factors including production requirements, part geometry, coating material, and system design.

This comprehensive guide will explore the key considerations when choosing a reciprocator for your coating system, explain the technical parameters involved, and provide practical insights to optimize your powder coating process.

Understanding Reciprocators in Coating Systems

What Is a Reciprocator?

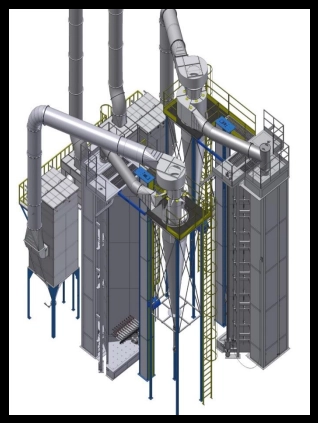

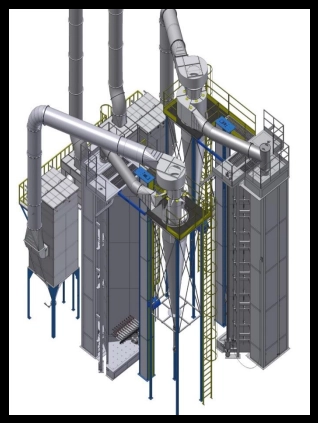

A reciprocator is a motion system used in automated coating lines to move spray guns in a controlled back-and-forth (reciprocating) motion. This enables uniform application of coatings on parts of varying sizes and shapes. Reciprocators can be configured to move vertically or horizontally depending on the system layout and coating requirements.

Role of Reciprocators in Powder Coating

In powder coating, reciprocators help achieve consistent film thickness and coverage by controlling the dwell time of the spray guns over the parts. They work in conjunction with conveyor speeds and gun parameters to balance coating efficiency and material usage.

Key Factors to Consider When Choosing a Reciprocator

1. Production Line Speed and Throughput

Your reciprocator must synchronize with the conveyor speed to ensure complete and uniform coverage. Choosing a reciprocator speed that is an integer multiple of the conveyor speed simplifies system design and helps avoid undesirable coating patterns such as “W” patterns caused by overlapping strokes.

For example, if your conveyor speed is 8 feet per minute (fpm), selecting a reciprocator speed of 80 fpm (10 times conveyor speed) can optimize stroke length and coating uniformity[1].

2. Part Size and Geometry

The height and shape of the parts being coated influence the required stroke length and number of guns. Taller parts require longer strokes or multiple guns arranged vertically to cover the entire surface.

The reciprocator stroke must be calculated based on the spray pattern diameter and the part height. Dividing the part height by the stroke length determines how many guns are needed to ensure full coverage without gaps or excessive overlap[1][3].

3. Gun Arrangement and Number of Guns

Reciprocators typically use multiple guns mounted on a carriage that moves along the stroke path. The number of guns depends on line speed, coating thickness, and transfer efficiency rather than the gun movement method alone.

While reciprocators may require fewer guns than oscillators in some cases, this varies based on stroke speed and part dimensions. Proper configuration ensures uniform film thickness and compensates for any gun failures[3].

4. Coating Material and Transfer Efficiency

Different powder coatings have varying transfer efficiencies, which affect how much material actually adheres to the part versus how much is lost as overspray. For flat, solid parts, transfer efficiency can be as high as 75%, while parts with holes or complex shapes may have efficiencies as low as 40%.

Understanding your coating material's transfer efficiency helps determine the required gun output and reciprocator speed to achieve the desired coverage without wasting powder[1].

5. Stroke Speed and Dwell Time

The reciprocator's stroke speed must balance coverage quality and production rate. Too fast a stroke reduces dwell time, leading to thin or uneven coatings; too slow a stroke reduces throughput.

Calculations involving the charge on powder particles and gun output help optimize stroke speed to maximize coating efficiency while maintaining quality[1][5].

6. Load Capacity and Maintenance

Reciprocators must support the weight of guns and holders, typically up to 50 kg or more, and operate quietly with smooth acceleration and braking. Integrated holding brakes and easy maintenance features improve system reliability and uptime[5][7].

Technical Considerations for Reciprocator Selection

H2: Calculating Reciprocator Stroke and Speed

- Stroke Length: Determined by the part height and spray pattern diameter. The stroke should cover the entire height with minimal overlap.

- Stroke Speed: Should be chosen to allow effective dwell time for powder adhesion.

- Speed Ratio: The ratio of reciprocator speed to conveyor speed should be an integer to simplify synchronization and avoid coating defects[1].

H3: Number of Guns Required

- Calculate based on part height divided by stroke length.

- Consider coating thickness and transfer efficiency.

- Ensure redundancy to compensate for potential gun failures[3].

H3: Minimizing Overspray and Edge Buildup

- Over-stroking is used to avoid heavy buildup at part edges.

- Reciprocators with horizontal gun arrangements may cause more overspray at edges compared to oscillators.

- Proper stroke length and gun positioning reduce powder waste[3].

Practical Tips for Choosing the Right Reciprocator

Align Reciprocator Speed with Conveyor Speed

Choosing a reciprocator speed that is a multiple of the conveyor speed simplifies system control and improves coating uniformity.

Match Stroke Length to Part Dimensions

Customize stroke length and number of guns to the height and shape of the parts for optimal coverage.

Consider Coating Material Characteristics

Account for transfer efficiency and powder charge to select appropriate gun output and reciprocator speed.

Evaluate System Load and Maintenance Needs

Ensure the reciprocator can handle the weight of guns and accessories and offers easy maintenance to reduce downtime.

Test and Validate in Real Conditions

Lab testing with actual parts and powders will confirm calculations and help fine-tune reciprocator settings for best results.

Advanced Features and Innovations

Modern reciprocators may include:

- Programmable control units for precise stroke and speed adjustments.

- Incremental pulse generators for exact positioning.

- Quiet operation and energy-efficient motors.

- Integrated brakes for safety and stability.

- Capability to store multiple stroke programs for different products[5][7][9].

Frequently Asked Questions (FAQs)

Q1: What is the ideal reciprocator speed relative to conveyor speed?

A1: It is best to choose a reciprocator speed that is an integer multiple of the conveyor speed to simplify synchronization and avoid coating defects.

Q2: How do I determine the number of guns needed?

A2: Divide the part height by the reciprocator stroke length and consider coating thickness and transfer efficiency to calculate the required number of guns.

Q3: Can a reciprocator compensate for a failed gun?

A3: No, if a gun fails partially or fully, the coating thickness will be uneven. Proper maintenance and redundancy are necessary to avoid coverage issues.

Q4: How does part geometry affect reciprocator choice?

A4: Complex or tall parts require longer strokes or more guns to ensure complete coverage without gaps or excessive overlap.

Q5: What maintenance considerations are important for reciprocators?

A5: Load capacity, smooth operation, integrated brakes, and ease of access for maintenance are key factors to ensure reliable performance.

[1] https://p2infohouse.org/ref/25/24701.pdf

[2] https://patents.google.com/patent/CN105188958B/zh

[3] https://www.pcimag.com/articles/94041-let-the-math-drive-the-mover

[4] https://www.nsfc.gov.cn/nsfc/cen/yxcg/06/2017-03-31.pdf

[5] https://ijritcc.org/download/conferences/ICMTEST_2016/ICMTEST_2016_Track/1461912215_29-04-2016.pdf

[6] https://stm-assoc.org/wp-content/uploads/2024/08/2018_01_18_STM20151208-1.pdf

[7] https://www.gemapowdercoating.com/fileadmin/documents/User_Manuals/English/Reciprocators_and_Axes/Z_Vertical_Axes/ZA04-en.pdf

[8] https://engineering.purdue.edu/~byao/Thesis/%E7%A1%95%E5%A3%AB%E8%AE%BA%E6%96%87-%E9%9F%A9%E4%BF%A1_ZJU16.pdf

[9] https://www.powdergun.com/Reciprocator.htm

[10] https://blog.csdn.net/xiaoheihei_/article/details/126758056

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.