Content Menu

● Introduction

● Understanding Coating Systems

>> Conventional Coating Systems

>> Integrated Control Systems

● Technical Superiority of Integrated Control Systems

>> Precision and Consistency

>> Closed-Loop Control

>> Advanced Process Monitoring

● Operational Benefits

>> Enhanced Productivity

>> Reduced Resource Waste

>> Streamlined Workflow Integration

● Quality Assurance and Traceability

>> Real-Time Quality Control

>> Data-Driven Traceability

● Safety and Environmental Advantages

>> Operator Safety

>> Environmental Compliance

● Flexibility and Scalability

>> Adaptability to Product Variations

>> Modular and Upgradeable Design

● Case Study: Pipe Coating in the Oil & Gas Industry

● Comparative Analysis: Integrated vs. Conventional Coating Systems

● Challenges and Considerations

● Future Trends

● Frequently Asked Questions

Introduction

In today's manufacturing landscape, the demand for high-quality, consistent, and efficient coating processes is greater than ever. Coating systems are vital in industries ranging from automotive and aerospace to oil and gas, where surface protection, durability, and aesthetics are essential. Traditionally, conventional coating systems have relied on manual operations or semi-automated controls, often resulting in inefficiencies, inconsistent quality, and increased operational costs. The advent of integrated control systems represents a significant leap forward, offering advanced automation, real-time monitoring, and precise process management. This article explores how integrated control systems outperform conventional coating systems, examining their technical advantages, operational benefits, and impact on quality, safety, and sustainability.

Understanding Coating Systems

Conventional Coating Systems

Conventional coating systems typically involve manual or semi-automated processes. Operators adjust parameters such as spray pressure, gun distance, and coating thickness based on experience and periodic checks. These systems may use basic timers, analog controls, and limited feedback mechanisms. While they have served industries for decades, their limitations become apparent in high-mix, low-volume production environments or where stringent quality standards are required.

Integrated Control Systems

An integrated control system combines digital automation, centralized process management, and real-time data analytics. These systems utilize programmable logic controllers (PLCs), touch-screen interfaces, and closed-loop feedback to monitor and control every aspect of the coating process. Parameters such as spray pattern, material flow, gun positioning, and environmental conditions are precisely managed, often from a single operator interface. Integrated systems can automatically adapt to changes in product specifications, material types, and production schedules, minimizing human intervention and error.

Technical Superiority of Integrated Control Systems

Precision and Consistency

One of the most significant advantages of integrated control systems is their ability to deliver consistent coating thickness and uniform coverage. Automated feedback mechanisms continuously monitor the application process, adjusting parameters in real time to maintain the desired film thickness across complex geometries. This precision minimizes defects such as runs, sags, or thin spots, which are common in manual or less sophisticated systems.

Closed-Loop Control

Integrated systems employ closed-loop control, using sensors and digital feedback to ensure that process variables remain within specified limits. For example, the iControl® system features closed-loop digital flow modules that provide consistent, repeatable coating performance, even as environmental or material conditions change. This capability is crucial for industries where product quality and regulatory compliance are non-negotiable.

Advanced Process Monitoring

Modern integrated control systems offer comprehensive process monitoring and data logging. Operators can track key performance indicators (KPIs) such as material usage, cycle times, and coating thickness in real time. Historical data analysis enables predictive maintenance, process optimization, and continuous improvement initiatives.

Operational Benefits

Enhanced Productivity

Automated control systems significantly increase throughput by reducing manual intervention and streamlining changeovers. For example, advanced pipe coating machines can automatically adjust to different part specifications and production requirements without stopping the line. This flexibility is especially valuable in high-mix, low-volume environments, where frequent product changes are the norm.

Reduced Resource Waste

Precise control of material flow and spray patterns minimizes overspray and material waste. Integrated systems can optimize the use of coating materials, reducing costs and environmental impact. Automated cleaning and maintenance routines further enhance efficiency by minimizing downtime and extending equipment life.

Streamlined Workflow Integration

Integrated control systems are designed to interface seamlessly with other production equipment, such as blasting machines, curing ovens, and conveyors. This interoperability allows for the creation of fully automated production lines, reducing bottlenecks and manual handling.

Quality Assurance and Traceability

Real-Time Quality Control

Integrated systems enable real-time quality assurance through continuous monitoring and automated testing. Non-destructive testing methods can be applied during the coating process, eliminating the need to sacrifice finished products for inspection. This approach ensures that every coated part meets the required standards, reducing rework and scrap rates.

Data-Driven Traceability

Comprehensive data logging provides full traceability for each coated product. Operators can access detailed records of process parameters, material batches, and quality checks, supporting regulatory compliance and customer audits. This level of traceability is difficult to achieve with conventional systems, where manual record-keeping is prone to errors and omissions.

Safety and Environmental Advantages

Operator Safety

Integrated control systems reduce the need for manual intervention in hazardous environments, such as spray booths handling volatile organic compounds (VOCs) or high-temperature curing ovens. Automated controls and enclosed systems protect operators from exposure to harmful substances and dangerous conditions.

Environmental Compliance

Advanced systems incorporate features such as complete VOC capture, efficient material usage, and optimized airflow control to minimize environmental impact. These capabilities help facilities meet stringent environmental regulations and reduce their carbon footprint.

Flexibility and Scalability

Adaptability to Product Variations

Integrated control systems can handle a wide range of product sizes, shapes, and materials. Automated adjustment of parameters such as spray pattern, gun speed, and material mix allows for rapid changeovers and customization without manual reconfiguration.

Modular and Upgradeable Design

Many integrated systems are modular, allowing for future expansion and upgrades. Facilities can add new capabilities, such as additional spray guns or advanced analytics, without overhauling the entire system. This scalability protects investments and supports long-term growth.

Case Study: Pipe Coating in the Oil & Gas Industry

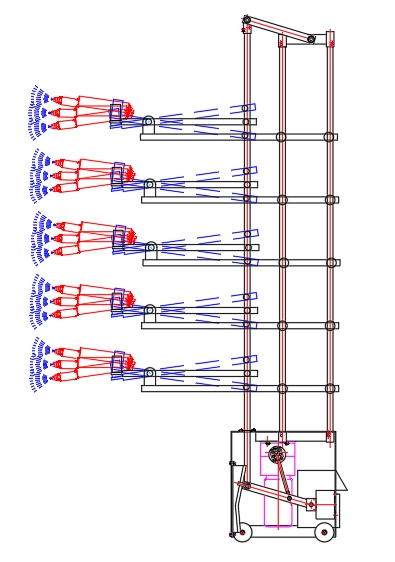

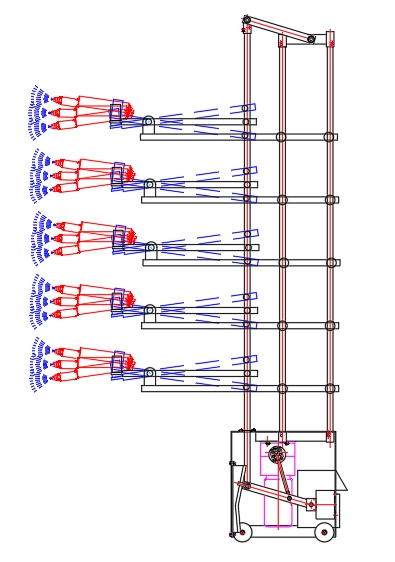

In the oil and gas sector, protecting pipes from corrosion and mechanical damage is critical. Traditional coating methods often struggle with inconsistent film thickness, lengthy processing times, and safety risks. The introduction of integrated control systems, such as the ID Spray Coater, has transformed this process.

Key improvements include:

- Consistent Coating Thickness: Automated feedback ensures even distribution of coating material, reducing the risk of localized corrosion.

- Process Control: Operators can precisely control material ratios, feed rates, and spray patterns, adapting to different pipe specifications on the fly.

- Streamlined Drying: Integrated drying processes reduce total cycle time from 10–12 hours to as little as 1–2 hours, boosting productivity.

- Quality Control: Real-time, non-destructive testing verifies coating quality without sacrificing finished products.

- Environmental Protection: Enclosed spray booths capture VOCs and maintain controlled airflow, protecting both workers and the environment.

These advancements demonstrate the tangible benefits of integrated control systems over traditional approaches in demanding industrial applications.

Comparative Analysis: Integrated vs. Conventional Coating Systems

| Feature/Benefit | Conventional System | Integrated Control System |

| Coating Consistency | Variable, operator-dependent | Highly consistent, automated |

| Process Control | Manual/semi-automated | Fully automated, closed-loop |

| Changeover Time | Lengthy, manual adjustments | Rapid, automated |

| Material Usage | Higher waste, less efficient | Optimized, minimal waste |

| Quality Assurance | Periodic, manual inspections | Real-time, automated monitoring |

| Traceability | Limited, manual records | Comprehensive, digital logs |

| Operator Safety | Higher exposure to hazards | Reduced exposure, automated |

| Environmental Compliance | Basic controls, higher emissions | Advanced controls, low emissions |

| Scalability | Limited, difficult to upgrade | Modular, easily upgradeable |

Challenges and Considerations

While integrated control systems offer substantial benefits, their implementation requires careful planning and investment. Key considerations include:

- Initial Cost: The upfront investment in automation and digital controls can be significant. However, long-term savings in material, labor, and maintenance often justify the expenditure.

- Training: Operators and maintenance personnel must be trained to manage and troubleshoot advanced systems.

- Integration: Compatibility with existing equipment and processes must be assessed to ensure seamless operation.

- Maintenance: While automated systems reduce manual intervention, they require regular calibration and software updates to maintain peak performance.

Future Trends

The evolution of integrated control systems continues, driven by advances in artificial intelligence, machine learning, and the Industrial Internet of Things (IIoT). Future systems will offer even greater predictive capabilities, self-optimization, and remote diagnostics, further enhancing efficiency, quality, and sustainability.

Frequently Asked Questions

1. What is the main difference between an integrated control system and a conventional coating system?

An integrated control system automates and centralizes process management, offering real-time monitoring and precise control, while conventional systems rely more on manual adjustments and periodic checks.

2. How does an integrated control system improve coating quality?

It uses closed-loop feedback and automated adjustments to maintain consistent coating thickness and uniform coverage, reducing defects and rework.

3. Are integrated control systems suitable for all industries?

Yes, they are adaptable to various industries, including automotive, aerospace, oil and gas, and general manufacturing, especially where quality and efficiency are critical.

4. What are the environmental benefits of integrated control systems?

They minimize material waste, optimize energy usage, and incorporate features such as VOC capture and efficient airflow control to reduce environmental impact.

5. Is it difficult to upgrade from a conventional to an integrated control system?

While the transition requires investment and planning, many integrated systems are designed to interface with existing equipment, making upgrades feasible and scalable.

6. How does data logging in integrated systems support regulatory compliance?

Automated data logging provides detailed, tamper-proof records of process parameters and quality checks, facilitating audits and compliance with industry standards.

7. Can integrated control systems reduce operational costs?

Yes, by optimizing material usage, reducing labor requirements, and minimizing downtime, integrated systems can significantly lower overall operational costs.

[1] https://www.nordson.com/en/products/industrial-coating-systems-products/icontrol-2---integrated-control-system

[2] https://blog.se.com/industry/machine-and-process-management/2022/05/31/integrated-process-control-for-paints-and-coating-business/

[3] https://arnoldmachine.com/resources/best-coating-system-for-pipe-coating-in-the-oil-gas-industry/

[4] https://ems-powdercoating.com/automated-coating-systems/

[5] https://coastisi.com/nordson-system-controls/

[6] https://www.ee.cityu.edu.hk/~gchen/pdf/Writing.pdf

[7] https://nc-p-001.sitecorecontenthub.cloud/api/public/content/a6a686d8fc1c497d89d71e1b687b267d?v=b0683c0d

[8] https://bbs.huaweicloud.com/blogs/359594

[9] https://jphe.amegroups.org/article/view/4265/10863

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.