Content Menu

● Understanding the Electrostatic Spray Gun

● Routine Cleaning Procedures

>> Why Cleaning is Critical

>> Daily Cleaning Steps

>> Weekly Deep Cleaning

● Inspection and Replacement of Key Components

>> Visual and Functional Inspections

>> Replacement Intervals

● Troubleshooting Common Issues

>> Inconsistent Spray Patterns

>> Poor Electrostatic Charging

>> Leaks or Fluid Drips

>> Trigger Malfunction

● Best Practices to Extend Electrostatic Spray Gun Life

>> Proper Handling and Storage

>> Use Compatible Materials

>> Regular Calibration and Testing

>> Professional Servicing

● Summary

● Frequently Asked Questions

>> Q1: How often should I clean my electrostatic spray gun?

>> Q2: What materials can damage an electrostatic spray gun?

>> Q3: How do I know if my electrode needs replacing?

>> Q4: Can I perform maintenance myself or should I hire a professional?

>> Q5: What causes poor paint transfer efficiency in electrostatic guns?

Electrostatic spray guns are essential tools in various industries, from automotive painting to industrial coatings and even agricultural applications. Their efficiency and precision can dramatically improve coating quality, reduce material waste, and enhance overall productivity. However, to achieve these benefits, maintaining the electrostatic spray gun properly is crucial. Improper maintenance can lead to poor spray patterns, inconsistent charging, equipment failure, and increased operational costs.

This comprehensive guide will delve into the key maintenance tips necessary to maximize the performance of your electrostatic spray gun. We will explore routine cleaning procedures, component inspection, troubleshooting, and best practices to ensure long-term durability and optimal performance.

Understanding the Electrostatic Spray Gun

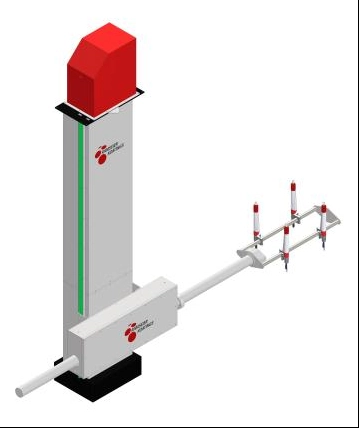

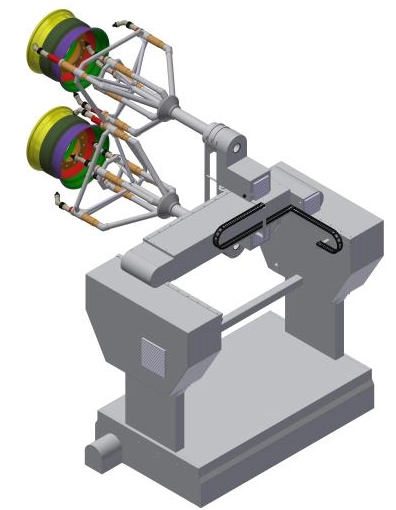

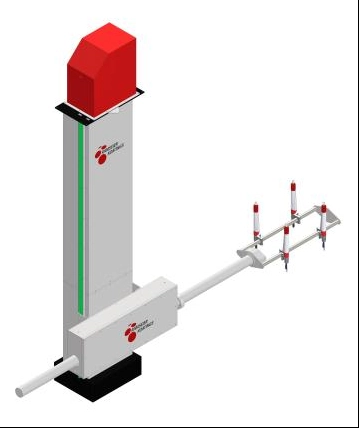

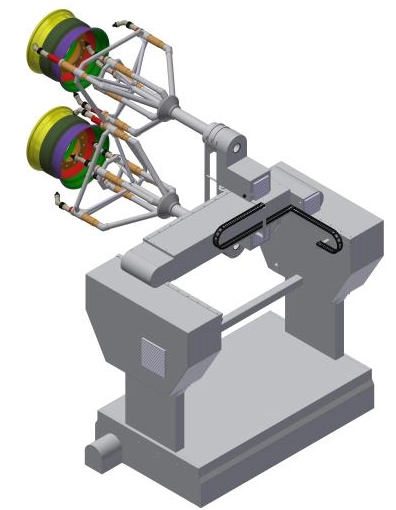

Before diving into maintenance, it is important to understand how an electrostatic spray gun functions. The gun applies an electrical charge to the paint or coating material as it passes through the nozzle, causing the particles to be attracted to the grounded target. This electrostatic effect improves the transfer efficiency of the coating, minimizes overspray, and allows for even coverage.

The main components of an electrostatic spray gun include:

- The spray nozzle

- The charging electrode or emitter

- The fluid delivery system

- High voltage power supply

- Control switches and regulators

Due to the precision required in these parts, regular maintenance is necessary to prevent issues that might affect the charging process or coating quality.

Routine Cleaning Procedures

Why Cleaning is Critical

Paint and coating materials are often sticky, viscous, and prone to clogging. Residue buildup in the spray gun can interrupt the flow of material, distort the spray pattern, and reduce the electrical charge concentration at the nozzle.

Regular cleaning not only prevents these problems but also extends the lifespan of the spray gun's components.

Daily Cleaning Steps

- Flush the Gun After Every Use: Immediately after spraying, flush the system with the appropriate cleaning solvent. This removes residual paint or coating from the fluid passages.

- Disassemble and Clean the Nozzle: Remove the nozzle and clean it with a soft brush and solvent. Avoid abrasive materials that could damage the delicate components.

- Clean the Electrode: Carefully clean the electrode to remove any buildup that can impede the electric charge.

- Wipe External Surfaces: Use a lint-free cloth to wipe the exterior of the gun, preventing dust and debris from accumulating.

Weekly Deep Cleaning

On a weekly basis or after extensive use, perform deeper maintenance:

- Fully disassemble the spray gun according to manufacturer instructions.

- Soak parts such as nozzles and internal fluid passages in cleaning solvent.

- Inspect and clean seals and gaskets to prevent leaks.

- Lubricate moving parts with appropriate lubricants if recommended.

Inspection and Replacement of Key Components

Visual and Functional Inspections

Conduct periodic inspections of your electrostatic spray gun to identify wear and tear or damage:

- Nozzle Condition: Check for nicks, cracks, or worn edges. A damaged nozzle can distort spray patterns.

- Electrode Wear: The charging electrode should be free from corrosion or deformation.

- Seals and O-Rings: Examine these for brittleness, cracks, or deformation that may cause leaks.

- Electrical Connections: Ensure wires and connectors are intact, secure, and free from oxidation.

- Gun Trigger and Controls: Verify smooth operation and responsiveness of the trigger mechanism.

Replacement Intervals

Some parts require scheduled replacement irrespective of visible wear:

- Electrodes: Typically, electrodes should be replaced annually or as recommended due to their impact on charging efficiency.

- Seals and O-rings: Replace more frequently in high-use environments to maintain fluid containment.

- Nozzles: Replace when wear affects the spray quality.

Troubleshooting Common Issues

Understanding common problems can greatly reduce downtime by enabling quick corrective action.

Inconsistent Spray Patterns

- Cause: Clogged nozzle or improper cleaning.

- Solution: Flush and clean the nozzle thoroughly; replace if damage is detected.

Poor Electrostatic Charging

- Cause: Worn or dirty electrodes, poor grounding, or electrical faults.

- Solution: Clean or replace the electrode; verify grounding connection; inspect high voltage supply.

Leaks or Fluid Drips

- Cause: Damaged seals, O-rings, or loose fittings.

- Solution: Replace worn seals and tighten fittings.

Trigger Malfunction

- Cause: Internal debris or mechanical wear.

- Solution: Disassemble to clean; replace worn parts.

Best Practices to Extend Electrostatic Spray Gun Life

Proper Handling and Storage

- Store the spray gun in a clean, dry environment.

- Use protective covers when not in use.

- Avoid dropping or exposing the gun to harsh chemicals unnecessarily.

Use Compatible Materials

- Ensure coating materials and solvents are compatible with gun components to prevent damage.

- Following manufacturer recommendations for materials helps avoid rapid degradation.

Regular Calibration and Testing

- Periodically test the gun's voltage output and spray pattern to ensure optimal operation.

- Calibration helps detect problems before they escalate.

Professional Servicing

- Schedule professional maintenance annually or biannually.

- Technicians can conduct in-depth diagnostics and replace parts efficiently.

Summary

Maximizing the performance of an electrostatic spray gun requires a dedicated regimen of cleaning, inspection, troubleshooting, and best practices in handling. Daily flushes, proper component care, timely replacement, and regular testing not only maintain consistent coating quality but also reduce costly downtime. Employing these maintenance tips will help you maintain a reliable, effective spray system that produces excellent finishes and operates efficiently for years.

Frequently Asked Questions

Q1: How often should I clean my electrostatic spray gun?

A: It is best to clean the spray gun immediately after each use with an appropriate solvent. Additionally, a deep cleaning once a week is recommended for optimal performance.

Q2: What materials can damage an electrostatic spray gun?

A: Harsh solvents not recommended by the manufacturer, abrasive cleaning tools, and incompatible coating materials can damage the gun's components.

Q3: How do I know if my electrode needs replacing?

A: Signs include visible corrosion, deformation, or if you notice a decrease in electrostatic charging efficiency.

Q4: Can I perform maintenance myself or should I hire a professional?

A: Routine cleaning and inspection can be done by operators, but more complex repairs and calibrations are better handled by trained technicians.

Q5: What causes poor paint transfer efficiency in electrostatic guns?

A: Common causes include dirty or worn nozzles, insufficient electrical charge, poor grounding, or incorrect spray parameters.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.