Content Menu

● Understanding Electrostatic Spray Guns

● Key Features of High-Performance Electrostatic Spray Guns

>> Superior Atomization Technology

>>> High-Quality Nozzle Design

>>> Adjustable Spray Patterns

>> Efficient Electrostatic Charging System

>>> Stable High Voltage Output

>>> Safe and Reliable Electrical Components

>> Ergonomic and Durable Design

>>> Lightweight and Comfortable Handling

>>> Robust Build Quality

>> Compatibility and Versatility

>>> Wide Range of Coatings

>>> Adaptability to Different Air Supply Systems

>> Efficient Paint Delivery System

>>> Reduced Paint Waste

>>> Easy Clean-Up and Maintenance

>> Advanced Control and Automation Features

>>> Digital Controls and Monitoring

>>> Integration with Automated Systems

● Additional Considerations When Choosing an Electrostatic Spray Gun

>> Cost vs. Performance Balance

>> Training and Technical Support

>> Environmental and Regulatory Compliance

● Frequently Asked Questions (FAQs)

>> Question 1: How does the electrostatic spray gun reduce paint usage?

>> Question 2: Can electrostatic spray guns be used for both liquids and powders?

>> Question 3: What safety precautions should be taken when using an electrostatic spray gun?

>> Question 4: How important is the nozzle size in an electrostatic spray gun?

>> Question 5: Are electrostatic spray guns suitable for outdoor use?

● Conclusion

Electrostatic spray guns have revolutionized paint application and coating industries by enhancing efficiency, reducing material waste, and delivering superior finishes. Whether you are a professional painter, automotive specialist, or manufacturing technician, choosing the right electrostatic spray gun can significantly impact your results. This article explores the top features to look for in a high-performance electrostatic spray gun to help you make an informed decision.

Understanding Electrostatic Spray Guns

Before diving into the specific features, it is essential to understand how electrostatic spray guns work. An electrostatic spray gun uses electrical charges to atomize and direct coating materials—such as paint—onto surfaces. The principle behind this is that the spray particles are electrically charged, and the target surface is oppositely charged or grounded. This charge attraction helps the particles wrap around objects, providing even coating and reducing overspray.

Key Features of High-Performance Electrostatic Spray Guns

Superior Atomization Technology

High-Quality Nozzle Design

A top-tier electrostatic spray gun should have advanced nozzle technology. The nozzle plays a significant role in breaking down the paint into fine droplets, allowing for a smooth and consistent finish. A high-performance gun will have nozzles engineered for optimal particle size and spray patterns, enabling precise control over how the coating material is distributed.

Adjustable Spray Patterns

Different projects require different spray patterns—fan, cone, or circular. A versatile electrostatic spray gun offers easy adjustment of spray patterns, allowing users to switch between wide-area coverage and detailed work without changing equipment. This adaptability improves efficiency and reduces downtime.

Efficient Electrostatic Charging System

Stable High Voltage Output

The core of an electrostatic gun's performance lies in its ability to generate and maintain a stable high voltage charge. A good spray gun should offer consistent voltage output to ensure effective charging of paint particles. This consistency directly affects how well the coating adheres to the target surface and minimizes waste.

Safe and Reliable Electrical Components

Safety is critical when working with high voltage equipment. Reliable electrostatic spray guns incorporate safety protections such as automatic voltage cutoffs, insulated handles, and grounded components to prevent electrical hazards. Look for products that comply with international safety standards for electrostatic equipment.

Ergonomic and Durable Design

Lightweight and Comfortable Handling

Professional painters may need to use the spray gun for extended periods. A lightweight gun designed with ergonomic features—such as soft grips, balanced weight distribution, and intuitive trigger mechanisms—reduces operator fatigue and enhances precision during long jobs.

Robust Build Quality

Durability is essential in industrial applications. High-performance electrostatic spray guns should be made from corrosion-resistant materials like stainless steel or reinforced composites. Robust build quality ensures long-lasting performance, even in harsh environments like automotive shops or manufacturing floors.

Compatibility and Versatility

Wide Range of Coatings

Different projects utilize various coatings—paints, primers, lacquers, or powder coatings. A versatile electrostatic spray gun is compatible with a broad spectrum of materials, allowing users to switch between coatings without requiring specialized equipment.

Adaptability to Different Air Supply Systems

Electrostatic spray guns often operate using compressed air. A high-performance model should easily connect to diverse air supply systems and offer adjustable air pressure settings to optimize spray characteristics depending on coating viscosity and application requirements.

Efficient Paint Delivery System

Reduced Paint Waste

One of the main advantages of electrostatic spraying is decreased material waste. The paint delivery system should be designed to minimize overspray and bounce-back. Features like precise flow control valves and automatic material recirculation can improve paint transfer efficiency and reduce unnecessary costs.

Easy Clean-Up and Maintenance

Paint guns that require frequent cleaning or complex maintenance increase downtime. High-performance spray guns incorporate features such as quick-disconnect nozzles, modular components, and easy access to internal parts. This not only speeds up maintenance but extends the lifespan of the equipment.

Advanced Control and Automation Features

Digital Controls and Monitoring

Modern electrostatic spray guns often integrate digital control panels or wireless connectivity features. These functionalities allow operators to set and monitor voltage, spray pressure, and flow rate in real-time, improving precision and repeatability in production environments.

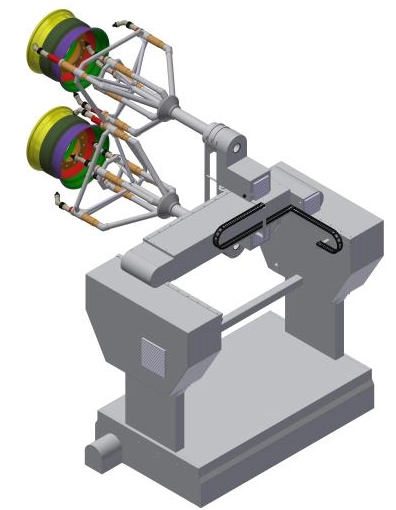

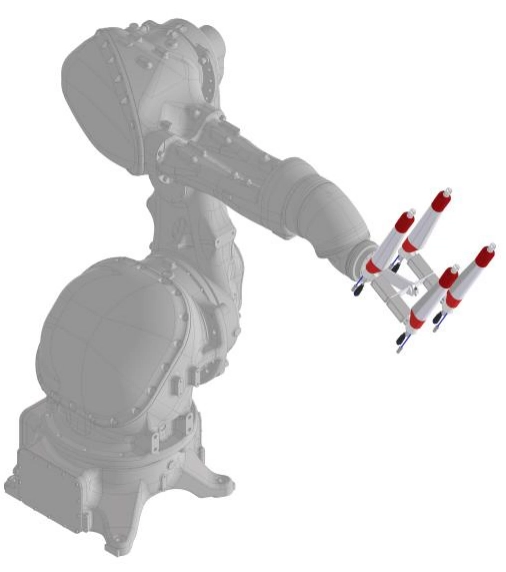

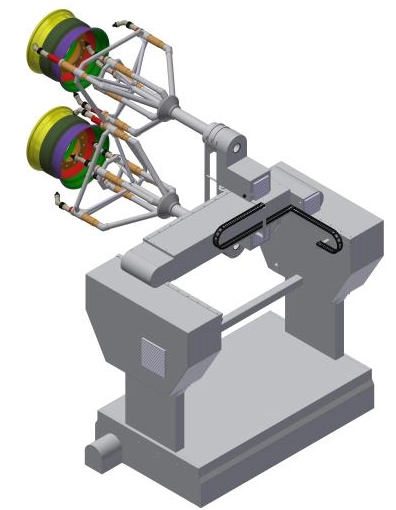

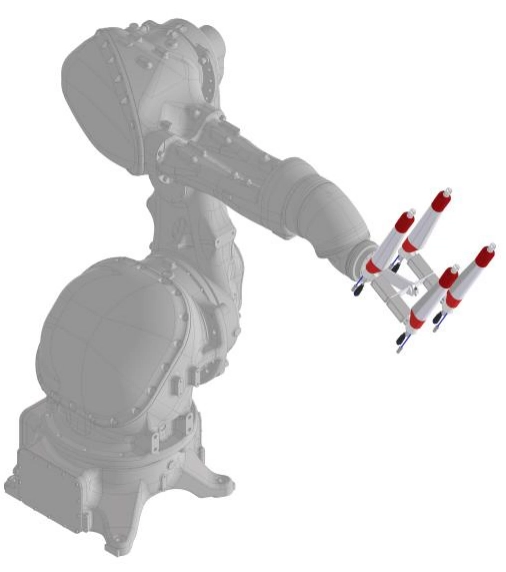

Integration with Automated Systems

In industrial or manufacturing plants, electrostatic spray guns are frequently part of automated coating lines. Compatibility with robotic arms, conveyor systems, or programmable logic controls enhances operational efficiency and consistency in high-volume production.

Additional Considerations When Choosing an Electrostatic Spray Gun

Cost vs. Performance Balance

While high-performance electrostatic spray guns come with advanced features, they usually entail a higher upfront cost. Assess your project needs carefully—buying equipment with capabilities beyond your requirements may not be cost-effective. Conversely, opting for a basic model may compromise quality or productivity.

Training and Technical Support

Electrostatic technology requires some level of expertise for optimal use. Manufacturers offering comprehensive training, technical support, and manuals make it easier for users to adapt and maintain the equipment correctly.

Environmental and Regulatory Compliance

Certain coatings and spray technologies must comply with environmental regulations, such as VOC emission limits or worker safety standards. Verify that the electrostatic spray gun you choose aligns with local and international regulatory requirements.

Frequently Asked Questions (FAQs)

Question 1: How does the electrostatic spray gun reduce paint usage?

Answer: The electrostatic charge causes paint particles to be attracted directly to the surface, significantly reducing overspray and bounce-back. This efficient transfer reduces the amount of paint wasted compared to conventional spray methods.

Question 2: Can electrostatic spray guns be used for both liquids and powders?

Answer: Yes, certain electrostatic spray guns are designed to handle both liquid coatings and powder coatings. However, many guns are specialized for one type, so check product specifications for compatibility.

Question 3: What safety precautions should be taken when using an electrostatic spray gun?

Answer: Operators should ensure grounding of the equipment and the surface being coated, wear appropriate personal protective equipment (PPE), and avoid moisture or conductive materials near high voltage components.

Question 4: How important is the nozzle size in an electrostatic spray gun?

Answer: Nozzle size directly affects the spray pattern and droplet size. Selecting the proper nozzle size is crucial for achieving desired finish quality and coating thickness.

Question 5: Are electrostatic spray guns suitable for outdoor use?

Answer: While many spray guns are intended for controlled indoor environments, some models are rugged enough for outdoor use. Weather conditions like wind and rain can interfere with spray quality, so take appropriate measures if working outside.

Conclusion

Selecting the right electrostatic spray gun involves evaluating multiple critical features, including atomization technology, charging systems, ergonomics, compatibility, and maintenance convenience. High-performance spray guns optimize coating efficiency, improve finish quality, and reduce costs through advanced design and intelligent controls. By carefully considering the features outlined in this guide, professionals can invest in electrostatic spray guns that meet their specific needs and deliver consistent, high-quality results in every application.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.