Content Menu

● Overview of Spray Gun Technologies

>> What is an Automatic Electrostatic Spray Gun?

>> What is a Conventional HVLP Spray Gun?

● How Automatic Electrostatic and HVLP Guns Work

>> Automatic Electrostatic Spray Gun Mechanism

>> Operation of Conventional HVLP Spray Guns

● Key Differences Between Automatic Electrostatic and HVLP Guns

>> Paint Transfer Efficiency

>> Finish Quality and Coverage

>> Material Compatibility

>> Environmental Impact and Overspray Reduction

>> Equipment Cost and Complexity

● Advantages of Automatic Electrostatic Spray Guns

>> Higher Paint Utilization

>> Improved Coverage on Intricate Surfaces

>> Consistent and Controlled Application

>> Reduced Drying Time

● Advantages of Conventional HVLP Spray Guns

>> Lower Initial Investment

>> Versatility in Materials

>> Ease of Use

>> Suitable for Smaller or Low-Volume Jobs

● Limitations and Challenges

>> Automatic Electrostatic Guns

>> Conventional HVLP Guns

● Practical Applications and Industries

>> Where Automatic Electrostatic Spray Guns Excel

>> Ideal Uses for HVLP Spray Guns

● Maintenance and Safety Considerations

>> Maintaining Automatic Electrostatic Spray Guns

>> Maintaining HVLP Spray Guns

>> Safety Precautions

● Summary

● Frequently Asked Questions (FAQ)

Spray guns are essential tools in many industries, from automotive painting to industrial coatings and furniture finishing. Two widely used types are the Automatic Electrostatic Spray Gun and the Conventional HVLP (High Volume Low Pressure) Gun. Understanding the differences between these spray guns can help professionals choose the most suitable equipment for their specific application, enhancing efficiency, finish quality, and cost-effectiveness.

This article delves into the technical aspects, operational characteristics, benefits, and limitations of both Automatic Electrostatic Spray Guns and Conventional HVLP Guns. It will also cover practical considerations like environmental impact, material usage, and maintenance. By the end of this comprehensive guide, you will have a clear understanding of which spray gun works best for your projects.

Overview of Spray Gun Technologies

What is an Automatic Electrostatic Spray Gun?

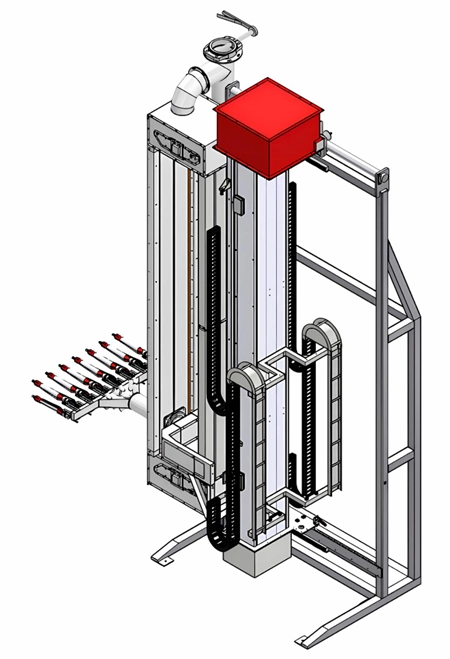

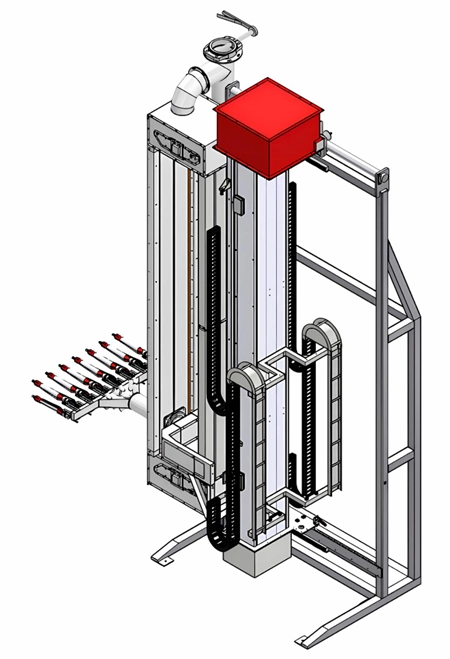

An Automatic Electrostatic Spray Gun uses electrostatic charge to improve coating adhesion and reduce overspray. The spray gun imparts a high-voltage electrical charge on paint particles as they exit the nozzle. These charged particles are attracted to the grounded workpiece, resulting in better coverage and less waste.

What is a Conventional HVLP Spray Gun?

A Conventional HVLP Spray Gun operates by using high volume, low pressure air to propel the paint toward the target surface. Unlike traditional high-pressure spray guns, HVLP guns produce less overspray and waste, but they do not utilize any electrostatic charge on the particles. This technology focuses on precise atomization with reduced air pressure.

How Automatic Electrostatic and HVLP Guns Work

Automatic Electrostatic Spray Gun Mechanism

- The gun produces a high voltage (typically 30,000 to 100,000 volts) to charge paint particles.

- Charged paint particles are attracted to the grounded object, wrapping around it for full coverage.

- The system often includes automatic controls to regulate voltage and flow for consistent results.

- The charged particles create a Coulombic attraction, reducing paint bounce-back and overspray.

Operation of Conventional HVLP Spray Guns

- Air pressure is reduced compared to conventional spray guns, typically under 10 PSI at the air cap.

- High volume of air moves paint particles in a soft, controlled spray pattern.

- Atomization is achieved by air turbulence breaking the paint into fine droplets.

- The lack of electrostatic charging relies purely on air mechanics for paint transfer.

Key Differences Between Automatic Electrostatic and HVLP Guns

Paint Transfer Efficiency

- Electrostatic guns achieve transfer efficiencies over 70%, meaning most paint reaches the surface.

- HVLP guns typically have transfer efficiencies between 50-70%, depending on operator skill and environmental conditions.

- Electrostatic charging reduces paint waste by attracting particles to the target, while HVLP relies on lower pressure air streams to minimize overspray.

Finish Quality and Coverage

- Electrostatic guns provide more uniform coverage, especially on complex shapes, due to the wrap-around effect.

- HVLP guns depend heavily on technique and can have uneven layers if not used carefully.

- Electrostatic coating often results in smoother finishes with fewer defects such as orange peel or runs.

Material Compatibility

- Automatic Electrostatic Spray Guns work best with conductive coatings like solvents and waterborne paints with sufficient conductivity.

- Some coatings, like thick polyurethanes, do not work well with electrostatic charging and require HVLP guns.

- HVLP guns are broadly compatible with nearly all coating materials without electrical considerations.

Environmental Impact and Overspray Reduction

- Electrostatic spraying significantly reduces overspray, leading to less volatile organic compounds (VOC) emitted into the atmosphere.

- HVLP guns produce less overspray than traditional high-pressure guns but more than electrostatic guns.

- Automatic electrostatic systems are considered more environmentally friendly due to efficient paint transfer and reduced emissions.

Equipment Cost and Complexity

- Electrostatic equipment involves higher initial investment due to voltage generators and grounding requirements.

- HVLP guns are generally less expensive, simpler to maintain, and widely used for their ease.

- Electrostatic systems require skilled operators and strict safety protocols managing high voltages.

Advantages of Automatic Electrostatic Spray Guns

Higher Paint Utilization

Automatic electrostatic spray guns minimize paint waste by actively attracting charged particles to the workpiece. This results in less material usage and lower overall paint consumption, which is advantageous for cost savings and environmental responsibility.

Improved Coverage on Intricate Surfaces

The electrostatic charge enables paint to coat difficult or recessed surfaces effectively, wrapping around edges and reducing the need for excessive coatings or multiple passes.

Consistent and Controlled Application

Automatic systems often come with programmable controls that ensure consistent voltage, paint flow, and atomization parameters, reducing human error and improving repeatability.

Reduced Drying Time

With less overspray and more even paint layers, drying times can be shortened, increasing production throughput and efficiency.

Advantages of Conventional HVLP Spray Guns

Lower Initial Investment

HVLP spray guns have a more straightforward design and are typically less expensive to purchase and maintain than electrostatic systems.

Versatility in Materials

They work well with almost any type of coating, including thicker materials that are unsuitable for electrostatic charging.

Ease of Use

HVLP guns require less technical knowledge and safety training compared to high-voltage electrostatic systems, making them ideal for smaller shops and hobbyists.

Suitable for Smaller or Low-Volume Jobs

Their simple setup and operation make HVLP guns perfect for occasional use where the high cost of electrostatics equipment cannot be justified.

Limitations and Challenges

Automatic Electrostatic Guns

- High voltage safety hazards require strict safety precautions.

- Limited to conductive coatings.

- Higher maintenance demands due to electronic components.

- More complex setup including grounding and voltage calibration.

Conventional HVLP Guns

- Lower transfer efficiency can lead to higher paint usage and cost.

- More overspray and environmental emissions compared to electrostatic guns.

- Operator skill heavily impacts finish quality.

- Less effective on complex or contoured surfaces.

Practical Applications and Industries

Where Automatic Electrostatic Spray Guns Excel

- Automotive manufacturing and refinishing.

- Appliance and metal furniture coating.

- Industrial equipment painting.

- Durable and uniform coatings on complex shapes.

Ideal Uses for HVLP Spray Guns

- Woodworking and furniture finishing.

- Custom automotive or motorcycle paint jobs.

- Arts and crafts requiring precise control.

- Small-scale or occasional painting projects.

Maintenance and Safety Considerations

Maintaining Automatic Electrostatic Spray Guns

- Regular inspection of high-voltage cables and connectors.

- Clean and calibrate voltage regulators.

- Frequent grounding checks for safety.

- Use manufacturer-recommended cleaning solvents to avoid damage.

Maintaining HVLP Spray Guns

- Routine disassembly and cleaning to prevent clogging.

- Periodic replacement of tips and nozzles.

- Maintain air compressor and regulators to ensure consistent air pressure.

- Follow manufacturer instructions for leak-free seals and tubing.

Safety Precautions

- Electrostatic guns require grounding of all parts and PPE to avoid electrical shock.

- HVLP guns necessitate proper ventilation due to solvent vapors.

- Both spray types require protective masks and eye protection against overspray and fumes.

Summary

The choice between Automatic Electrostatic Spray Guns and Conventional HVLP Guns depends on application requirements, budget, material type, and desired finish quality. Electrostatic guns are perfect for high-volume projects demanding efficiency, superior coverage, and environmental compliance. HVLP guns remain popular for their simplicity, versatility, and lower cost for small to medium tasks. By understanding the core differences and uses of each spray gun type, professionals can optimize their coating processes for better results.

Frequently Asked Questions (FAQ)

1. Can I use all types of paint with an automatic electrostatic spray gun?

No, electrostatic spray guns work best with conductive paints and coatings. Non-conductive or very thick materials may not charge properly and thus won't benefit from electrostatic application.

2. How much paint savings can I expect using an electrostatic spray gun?

Paint savings can range from 20% to 40%, depending on the application surface and how well the system is set up.

3. Are HVLP spray guns safer to use than electrostatic guns?

HVLP guns involve no high voltage, making them safer regarding electrical hazards. However, all spray operations require appropriate personal protective equipment and ventilation.

4. Can I switch between HVLP and electrostatic spray guns easily?

Yes, but electrostatic systems require specific grounding and voltage equipment, so it's not as simple as swapping the gun. Different preparation and setup are needed.

5. Which spray gun is better for curved or recessed surfaces?

Electrostatic guns provide superior coating on curved and recessed surfaces due to their charged particles wrapping around obstacles better than HVLP guns.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.