Content Menu

● Introduction

● What Is a Manual Spray Booth System?

>> Key Components of a Manual Spray Booth System

● Types of Manual Spray Booth Systems

>> Cross-Draft Spray Booths

>> Downdraft Spray Booths

>> Semi-Downdraft Spray Booths

● Why Partner with a Manual Spray Booth System Distributor?

>> Expertise and Consultation

>> Customization and Flexibility

>> Turnkey Solutions

>> After-Sales Support

● Features and Advantages of Manual Spray Booth Systems

>> 1. Controlled Environment

>> 2. Flexibility

>> 3. Cost-Effectiveness

>> 4. Safety Compliance

>> 5. Easy Maintenance

● How Manual Spray Booth System Distributors Serve Key Industries

>> Automotive and Transportation

>> Aerospace and Defense

>> Furniture and Woodworking

>> General Manufacturing

● Selecting the Right Manual Spray Booth System Distributor

>> Reputation and Experience

>> Customization Capabilities

>> Comprehensive Support

● The Process: From Consultation to Operation

>> 1. Needs Assessment

>> 2. System Design

>> 3. Manufacturing and Quality Control

>> 4. Installation and Training

>> 5. Ongoing Maintenance

● Frequently Asked Questions (FAQs)

● Conclusion

● Citations:

Introduction

In today's competitive manufacturing landscape, the demand for high-quality, efficient, and flexible coating solutions is greater than ever. As a leading Manual Spray Booth System Distributor, you play a crucial role in connecting manufacturers, OEMs, and brand owners with the right spray booth technologies to meet their production goals. This comprehensive guide explores the world of manual spray booth systems, their features, benefits, and how distributors can add value for their clients in diverse industries.

---

What Is a Manual Spray Booth System?

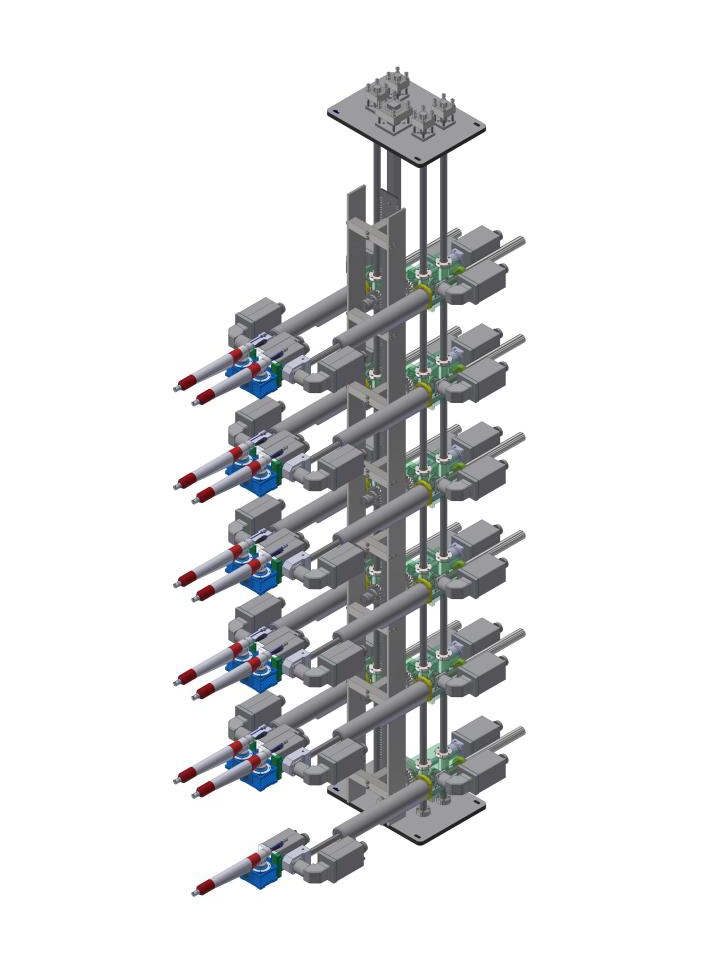

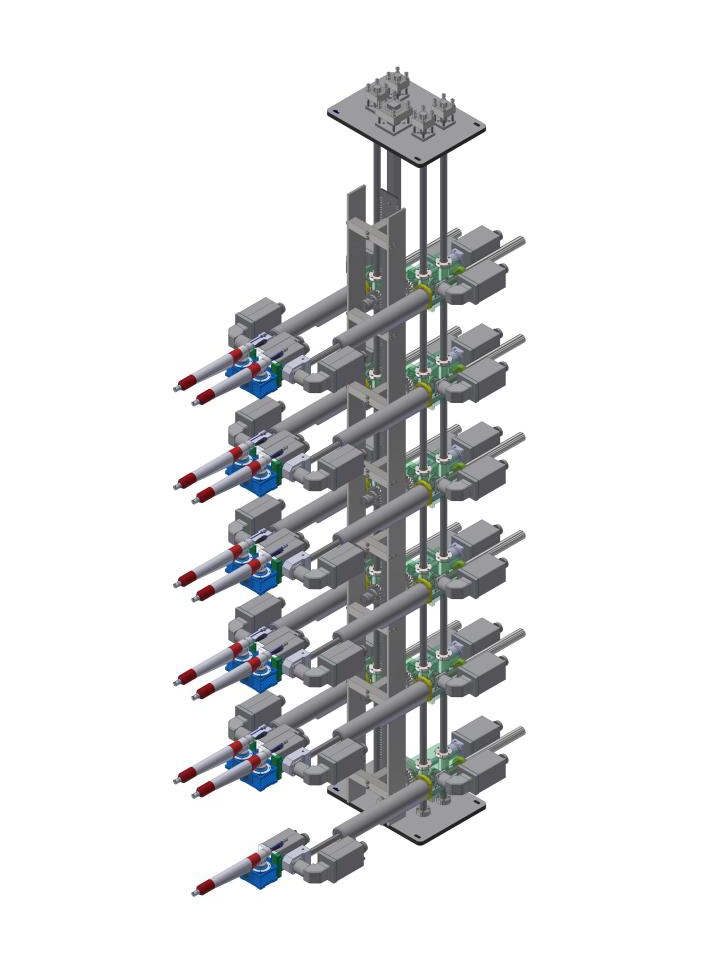

A manual spray booth system is a controlled environment designed for the application of coatings-such as paint or powder-by hand using spray guns. Unlike automated systems, manual booths rely on skilled operators to achieve precise and customized finishes, making them ideal for small to medium-sized production runs and jobs requiring flexibility or special attention[2][5].

Key Components of a Manual Spray Booth System

- Booth Enclosure: Typically constructed from metal or plastic, containing overspray and protecting the workspace[2].

- Ventilation and Filtration: Ensures removal of airborne particles and fumes, maintaining a safe and clean environment[2][6].

- Lighting: Well-lit interiors for accurate application and inspection[2][6].

- Powder or Paint Feed System: Delivers coating material to the spray gun.

- Spray Gun: The primary tool for manual application.

- Control Panel: For managing airflow, lighting, and safety features[6].

---

Types of Manual Spray Booth Systems

Cross-Draft Spray Booths

- Air flows horizontally across the booth.

- Cost-effective and easy to construct.

- Suitable for small parts and general applications but less ideal for large vehicles due to airflow limitations[5].

Downdraft Spray Booths

- Air flows vertically from ceiling to floor.

- Provides even airflow and superior finish quality.

- Best for large vehicles or high-end applications where finish consistency is critical[5].

Semi-Downdraft Spray Booths

- Combines features of cross-draft and downdraft.

- Air is filtered from both floor and sides, then exhausted at the ceiling.

- Reduces overspray and contaminants, offering a balance between price and performance[5].

---

Why Partner with a Manual Spray Booth System Distributor?

Expertise and Consultation

Distributors offer invaluable expertise, helping clients select the right booth type, size, and configuration for their application. They assess production needs, workspace constraints, and regulatory requirements to recommend optimal solutions[2][1].

Customization and Flexibility

A reputable Manual Spray Booth System Distributor collaborates with manufacturers to provide customized systems tailored to unique production requirements, including booth size, filtration, and safety features[2].

Turnkey Solutions

Many distributors offer end-to-end services, from design and fabrication to installation, training, and ongoing support. This ensures seamless integration into existing workflows and minimizes downtime[1][2].

After-Sales Support

Ongoing maintenance, spare parts, and technical support are essential for maximizing booth lifespan and performance. Distributors serve as a reliable partner throughout the equipment's lifecycle[2].

---

Features and Advantages of Manual Spray Booth Systems

1. Controlled Environment

Manual spray booths provide a dust-free, well-ventilated space, ensuring high-quality finishes and protecting operators from hazardous fumes[2][6].

2. Flexibility

Ideal for small batch production, prototyping, or jobs requiring frequent color changes and manual touch-ups[2].

3. Cost-Effectiveness

Manual systems are less expensive to purchase, operate, and maintain compared to fully automated alternatives, making them suitable for businesses with moderate production volumes[2][5].

4. Safety Compliance

Modern booths are designed with operator safety in mind, featuring explosion-proof fixtures, proper ventilation, and compliance with international safety standards[2][6].

5. Easy Maintenance

Simple construction and accessible components allow for straightforward cleaning and filter changes, reducing downtime and extending equipment life[2].

---

How Manual Spray Booth System Distributors Serve Key Industries

Automotive and Transportation

Manual spray booths are widely used in automotive repair, customization, and small-scale manufacturing for precise color matching and high-quality finishes[3][5].

Aerospace and Defense

Critical for coating complex parts and assemblies where manual control ensures thorough coverage and adherence to strict quality standards[1].

Furniture and Woodworking

Manual booths accommodate a variety of coatings and finishes, enabling artisans and manufacturers to achieve custom looks and textures[6].

General Manufacturing

From machinery to consumer goods, manual spray booths provide the flexibility needed for diverse product lines and rapid changeovers[2][5].

---

Selecting the Right Manual Spray Booth System Distributor

Reputation and Experience

Choose distributors with a proven track record, technical expertise, and strong relationships with leading manufacturers[2][1].

Customization Capabilities

Look for partners who offer tailored solutions, not just off-the-shelf products, to address your specific operational needs[2].

Comprehensive Support

Prioritize distributors who provide installation, training, and after-sales service to ensure long-term success[2][1].

---

The Process: From Consultation to Operation

1. Needs Assessment

Distributors work with clients to understand production goals, space constraints, and regulatory requirements[2].

2. System Design

Custom booth layouts, airflow patterns, and filtration systems are designed to maximize efficiency and safety[2].

3. Manufacturing and Quality Control

High-quality materials and rigorous testing ensure each booth meets performance and safety standards[2].

4. Installation and Training

Professional installation and operator training ensure smooth startup and optimal use of the system[2].

5. Ongoing Maintenance

Regular maintenance and support services keep the booth operating at peak efficiency[2].

---

Frequently Asked Questions (FAQs)

Q1: What are the main benefits of using a manual spray booth system?

A1: Manual spray booth systems offer a controlled environment for high-quality finishes, improved safety, flexibility for small batches, and cost-effectiveness compared to automated systems[2][5].

Q2: How do I choose the right type of manual spray booth for my application?

A2: Consider the size of your parts, production volume, desired finish quality, and available space. Distributors can help assess your needs and recommend the best booth type (cross-draft, downdraft, or semi-downdraft)[2][5].

Q3: What maintenance is required for manual spray booth systems?

A3: Regular cleaning, filter replacement, and inspection of ventilation and safety systems are essential for maintaining performance and compliance[2].

Q4: Can manual spray booth systems be customized?

A4: Yes, reputable distributors and manufacturers offer customization options for booth size, filtration, lighting, and safety features to meet specific production requirements[2].

Q5: What safety standards should a manual spray booth system meet?

A5: Systems should comply with local and international safety regulations, including proper ventilation, explosion-proof fixtures, and operator protection measures[2][6].

---

Conclusion

As a Manual Spray Booth System Distributor, you are a vital link in the industrial coating supply chain. By offering expert advice, customization, and ongoing support, you empower manufacturers to achieve superior finishes, operational efficiency, and regulatory compliance. Whether serving automotive, aerospace, furniture, or general manufacturing clients, the right manual spray booth system delivers lasting value and competitive advantage.

---

Citations:

[1] https://www.thomasnet.com/suppliers/usa/spray-booth-equipment-77063600

[2] https://www.ramseierkoatings.com/manual-spray-booth-system.html

[3] https://www.alliedmarketresearch.com/manual-paint-spray-machine-market-A169919

[4] https://p2infohouse.org/ref/25/24086.pdf

[5] https://www.alibaba.com/showroom/manual-paint-spray-booth.html

[6] https://www.ceflafinishing.com/en/products/manual-spray-booths-for-finishing

[7] https://www.rohnerspraybooths.com

[8] https://www.nordson.com/en/products/industrial-coating-systems-products/manual-powder-coating-booth

[9] https://www.spraysystems.com

[10] https://www.directindustry.com/industrial-manufacturer/manual-paint-booth-135764.html

[11] https://novavertapaintbooths.com

[12] https://globalfinishing.com

[13] https://totalfinishingsolutions.com

[14] https://www.prnewswire.com/news-releases/manual-paint-spray-machine-market-to-reach--3-442-3-million-globally-by-2032-at-2-8-cagr-allied-market-research-301948402.html

[15] https://wflitone.en.made-in-china.com/product/KJbUWdwVyjci/China-Manual-Powder-Coating-Paint-Spray-Booth-System.html

[16] https://www.codinter.com/en/spray-booths-a-complete-guide/

[17] http://www.spraybooth-online.com

[18] https://dataintelo.com/report/global-automobile-spray-booth-market

[19] https://www.dbmtec.com/en/industrial-spray-booths/

[20] https://www.wiseguyreports.com/reports/retractable-spray-booth-market

---

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.