Content Menu

● Table of Contents

● Introduction

● What is a Spray Gun Unit?

>> Components of a Spray Gun Unit

>> How Spray Gun Units Work

● What is a Reciprocator?

>> Design and Mechanism of a Reciprocator

>> Types of Reciprocators

● Function Comparison: Spray Gun Unit vs Reciprocator

● Applications in Industry

>> Automotive Industry

>> Furniture and Woodworking Industry

>> Electronics and Small Parts Coating

● Integration of Spray Gun Units and Reciprocators

>> Automation Systems and Robotics

>> Control Systems and Programming

● Maintenance and Troubleshooting

● Future Trends in Spray Guns and Reciprocators

● Conclusion

● FAQs

Spray guns and reciprocators represent two crucial technologies utilized in automation, manufacturing, and coating processes. Both tools enhance efficiency and quality in their respective applications but differ substantially in design, operation, and use cases. This article aims to explore and contrast Spray Gun Units and Reciprocators by delving into their functions, applications, and how they integrate into various industrial systems. By understanding these differences and synergies, industries can optimize production, reduce waste, and improve product consistency.

Table of Contents

- Introduction

- What is a Spray Gun Unit?

- Components of a Spray Gun Unit

- How Spray Gun Units Work

- What is a Reciprocator?

- Design and Mechanism of a Reciprocator

- Types of Reciprocators

- Function Comparison: Spray Gun Unit vs Reciprocator

- Applications in Industry

- Automotive Industry

- Furniture and Woodworking Industry

- Electronics and Small Parts Coating

- Integration of Spray Gun Units and Reciprocators

- Automation Systems and Robotics

- Control Systems and Programming

- Maintenance and Troubleshooting

- Future Trends in Spray Guns and Reciprocators

- Conclusion

- FAQs

- Word Count & Summary

***

Introduction

Spray Gun Units and Reciprocators serve as indispensable components in modern automated painting and coating systems. While a spray gun focuses on atomizing paint or coating material and delivering it evenly on a surface, a reciprocator moves the spray gun across the target either horizontally or vertically to ensure uniform coverage. They often work in tandem but are fundamentally different in purpose and design. Here, we explore each device's characteristics in detail, providing practical insights for industrial professionals, engineers, and decision-makers.

What is a Spray Gun Unit?

Components of a Spray Gun Unit

A Spray Gun Unit consists mainly of:

- Nozzle: The part where paint or coating material is atomized.

- Air Cap: Directs compressed air to assist atomization.

- Fluid Tip: Controls the amount of paint sprayed.

- Trigger or Valve: Regulates paint flow.

- Paint Cup or Reservoir: Holds the coating material.

- Body: The structural component housing internal connections.

These components work in unison to deliver a fine mist of paint or other coating materials.

How Spray Gun Units Work

Spray Gun Units operate by converting liquid paint into a fine spray or mist. Compressed air from the air cap forces the paint out of the fluid tip at high velocity, atomizing it. This allows for an even, smooth application over various surfaces. The user or automation system controls the spray volume, pressure, and pattern to suit different coating needs.

Spray Guns can be:

- Manual: Handheld and operator-controlled.

- Automatic: Mounted on robotic arms or fixed units for automated processes.

What is a Reciprocator?

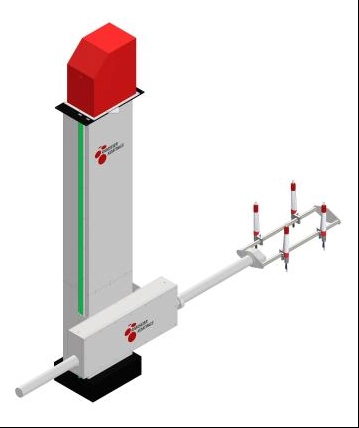

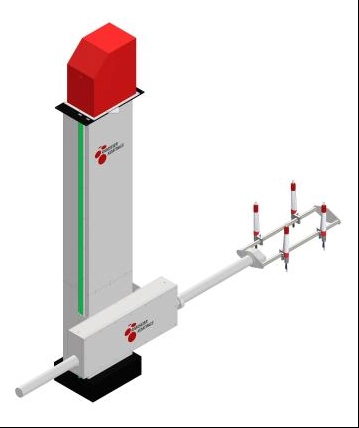

Design and Mechanism of a Reciprocator

A reciprocator is a mechanical device that moves a spray gun or other tooling back and forth in a linear path. This motion is typically horizontal but can be vertical or at any angle depending on design and application needs. The fundamental design involves:

- Reciprocating Arm: The moving part that carries the spray gun.

- Motor/Drive System: Powers the arm's motion.

- Guide Rails or Tracks: Ensures smooth and controlled movement.

- Control Interface: Manages speed, stroke length, and timing.

Types of Reciprocators

Reciprocators can be classified based on motion types and control:

- Single-axis Reciprocators: Move on a single linear path.

- Multi-axis Reciprocators: Combine more complex movement patterns with additional motors or linkages.

- Electromechanical Reciprocators: Use electric motors with precise controls.

- Hydraulic or Pneumatic Reciprocators: Utilize fluid power for motion.

Function Comparison: Spray Gun Unit vs Reciprocator

| Feature | Spray Gun Unit | Reciprocator |

| Primary Function | Atomize and spray coating materials | Produce controlled linear motion for spray |

| Operation Mode | Fluid flow and air pressure-based | Mechanical, motor-driven movement |

| Application Focus | Surface treatment | Motion and positioning of spray units |

| Usage | Handheld or fixed | Usually part of automation systems |

| Adjustability Parameters | Spray pattern, paint volume, pressure | Speed, stroke length, motion consistency |

| Impact on Coating Quality | Directly responsible for atomization | Ensures even coverage via structured motion |

While the spray gun controls the quality of the atomization and paint output, the reciprocator system ensures that this spray is consistently applied across the target surface by controlling spatial movement.

Applications in Industry

Automotive Industry

In automobile manufacturing, Spray Gun Units are used for applying primers, paints, and clear coats with high precision. Reciprocators move the spray guns along vehicle parts to ensure uniform paint coverage and smooth finishes. The combination greatly reduces paint waste and improves cycle times.

Furniture and Woodworking Industry

Spray guns apply finishes like varnishes and stains on wood surfaces, while reciprocators automate movement to cover broad surfaces like tabletops or cabinet doors evenly. This integration supports both aesthetics and protection of the wood.

Electronics and Small Parts Coating

For intricate small parts and electronics, miniaturized spray guns paired with precision reciprocators facilitate detailed coating without overspray. These systems help achieve consistent layers of conformal coatings or protective finishes.

Integration of Spray Gun Units and Reciprocators

Automation Systems and Robotics

Modern manufacturing relies on integrated systems where spray guns and reciprocators connect to robotic arms and automated conveyors. This synergy ensures high throughput and consistent results by synchronizing fluid delivery and controlled movement.

Control Systems and Programming

Advanced control units program the speed, pattern, and trigger timing of spray guns with reciprocator strokes. This programming capability allows customization for different materials, surfaces, and production scales, improving adaptability and efficiency.

Maintenance and Troubleshooting

Proper maintenance extends the life and performance of both spray guns and reciprocators:

- Spray Gun Unit Maintenance:

- Clean nozzles regularly to prevent clogging.

- Check seals and air caps for wear.

- Ensure fluid paths are free from dried paint residue.

- Reciprocator Maintenance:

- Lubricate moving parts to prevent wear and tear.

- Inspect motors and drive systems for consistency.

- Verify control alignment and calibrate stroke parameters.

Troubleshooting common issues involves identifying inconsistent spray patterns, irregular motion, or mechanical noises, and responding with targeted cleaning or part replacement.

Future Trends in Spray Guns and Reciprocators

Innovation continues to propel both spray technology and motion systems:

- Smart Spray Guns: Integrated sensors for real-time monitoring of flow and atomization quality.

- Enhanced Reciprocators: Adaptive motion systems with AI-driven speed and pattern optimization.

- Eco-friendly Coatings: Systems designed for high transfer efficiency minimizing environmental impact.

- Wireless Control: Remote operation and monitoring for greater flexibility and safety.

- Modular Units: Easily interchangeable parts to support rapid customization for different job requirements.

Such trends indicate an evolving industry focused on precision, efficiency, and sustainability.

Conclusion

Spray Gun Units and Reciprocators, while intrinsically connected in application, serve distinct yet complementary roles in automated coating and painting processes. Understanding the specific functions of each enables manufacturers and engineers to implement systems that maximize productivity and quality. Integration and thoughtful maintenance are key to achieving the full potential of these technologies, while ongoing innovations promise even greater advancements in industrial painting and coating capabilities.

FAQs

Q1: Can a spray gun operate without a reciprocator?

A1: Yes, spray guns can be manually operated or fixed in place for static spraying, but reciprocators improve coverage and consistency in automated setups.

Q2: What materials can be applied using spray gun units?

A2: Spray guns apply paints, varnishes, primers, adhesives, and a variety of liquid coatings depending on the nozzle and fluid design.

Q3: How do reciprocators improve coating quality?

A3: By providing uniform, consistent motion, reciprocators prevent uneven layers and overspray, ensuring smoother finishes.

Q4: Are spray guns and reciprocators used outside of painting?

A4: Yes, they are also used in applying adhesives, lubricants, sealants, and other coatings in various industries.

Q5: What maintenance is critical for prolonging reciprocator life?

A5: Regular lubrication, timely part replacements, and ensuring proper calibration of the movement system are essential.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.