Content Menu

● Introduction

● Ramseier Koatings Technologies Holdings Ltd.: Pioneer in Electrostatic Spray Gun Systems

>> Legacy and Expertise

● Advanced Technologies Powered by Ramseier Koatings

>> Key Features of Smart 600 Spray Gun System

● Customized OEM Solutions for Global Clients

>> Tailored Manufacturing for Brand Owners and Distributors

>> Comprehensive Product Range Includes

● Industry Impact and Innovation

● Frequently Asked Questions (FAQs)

>> 1. What makes Ramseier Koatings the top manufacturer of spray gun units?

>> 2. How does the Smart 600 electrostatic spray gun improve coating efficiency?

>> 3. Can Ramseier Koatings customize spray gun units for specific client requirements?

>> 4. What technologies does Ramseier Koatings incorporate in their spray gun systems?

>> 5. How does Ramseier Koatings support clients after OEM manufacturing?

Introduction

When it comes to top manufacturers of spray gun units for electrostatic coating systems, Ramseier Koatings Technologies Holdings Ltd. stands at the forefront. As a distinguished OEM factory in China, Ramseier Koatings integrates decades of expertise, cutting-edge technology, and customized solutions designed for international electrostatic spray gun and coating system brands, wholesalers, and manufacturers. This article delves into the strengths of Ramseier Koatings, its innovative technologies, comprehensive OEM services, and its pivotal role in advancing electrostatic coating systems worldwide.

Ramseier Koatings Technologies Holdings Ltd.: Pioneer in Electrostatic Spray Gun Systems

Legacy and Expertise

Ramseier Koatings, a Hong Kong-based company with over 38 years of experience, is a *global leader* in the manufacturing of spray gun units tailored for electrostatic powder coating systems. The company focuses on integrating high-performance electrostatic spray guns, control systems, and powder supply units into seamless solutions optimized for efficiency and quality[3].

Originating from a strong European and Chinese collaboration, Ramseier Koatings absorbed decades of industry knowledge from its founding through strategic acquisitions since 1983. This synergy has enabled Ramseier Koatings to dominate the OEM manufactory landscape by providing customized products that exactly meet the demands of global brand owners and bulk suppliers[2][3].

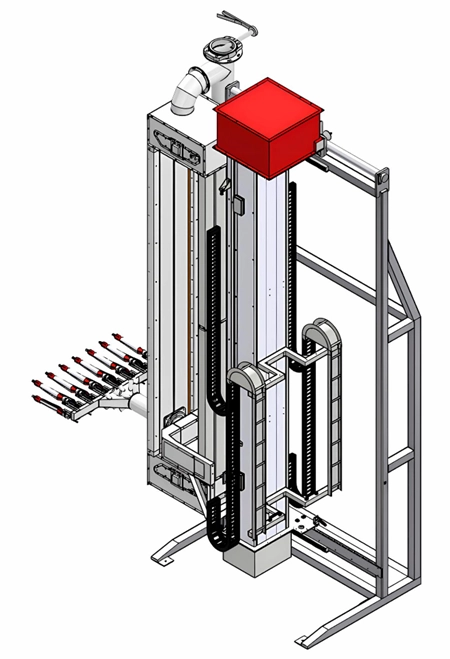

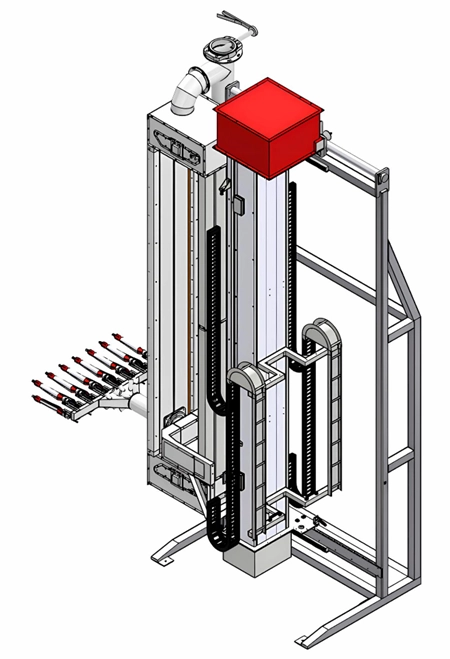

Advanced Technologies Powered by Ramseier Koatings

Ramseier Koatings' top-selling product, the Smart 600 electrostatic powder coating spray gun, exemplifies their innovation as a top manufacturer of spray gun units. It incorporates the patented Total Charge Control (TCC®) technology – an industry milestone[1][3].

Key Features of Smart 600 Spray Gun System

- Five Electrostatic Charge Modes: Automatic, Manual, and preset configurations for different surface types and recoats.

- Smart Control Unit (SCU-S600 Mk2): Allows seamless group or individual gun parameter adjustments remotely, ensuring operational flexibility.

- SmartClean Technology: Maintains efficiency by air jet cleaning of discharge needle and powder paths for consistent particle charging.

- Enhanced Safety: Optional earth fault detection for safer, reliable operation.

- Superior Transfer Efficiency: Up to 90% powder transfer rate reducing waste dramatically.

- Programmability: Easily programmable for up to 100 electrostatic settings to tailor coating processes.

- User-friendly Interface: Designed to enhance operator productivity and reduce costs[1][3].

Such technical sophistication not only guarantees a uniform and high-quality coating finish but significantly improves economic efficiency for OEM clients — a core appeal for those seeking the top manufacturer of spray gun units.

Customized OEM Solutions for Global Clients

Tailored Manufacturing for Brand Owners and Distributors

Ramseier Koatings provides turnkey, custom OEM manufacturing services for foreign electrostatic spray gun system brand owners, wholesalers, and producers. Their ability to customize spray gun units and related electrostatic coating system components according to client specifications enables these partners to maintain competitive advantage with exclusive, patented technologies and reliable quality[2][3][5].

Comprehensive Product Range Includes

| Product Category | Description |

| Electrostatic Spray Guns | Advanced powder charging nozzles for efficient coating |

| Automated Spray Booth Systems | Customized booths enhancing powder application process |

| Powder Supply Systems | Precision powder feeders and hoppers for consistent flow |

| Control Systems | Intelligent monitoring and data management platforms |

| Closed-loop Powder Management Systems | Powder recovery and rapid color change technologies |

This broad yet specialized product range supports diverse production scales and operational needs, making Ramseier Koatings a preferred top manufacturer of spray gun units in the electrostatic coating industry[1][2][5].

Industry Impact and Innovation

Ramseier Koatings' steady commitment to R&D and innovation has resulted in numerous patented products beyond the spray gun itself, such as the Quantum Charge technology, MPC closed-loop powder management systems, and color change technologies, all reinforcing their market leadership. These innovations not only enhance coating uniformity and reduce operational downtime but also elevate product longevity and environmental sustainability[2].

Frequently Asked Questions (FAQs)

1. What makes Ramseier Koatings the top manufacturer of spray gun units?

Ramseier Koatings combines decades of experience, patented technologies like TCC, customizable OEM capabilities, and a comprehensive product ecosystem to deliver high-performance, reliable, and efficient electrostatic spray gun systems globally[1][3].

2. How does the Smart 600 electrostatic spray gun improve coating efficiency?

The Smart 600 uses Total Charge Control technology to optimize powder particle charging, achieving up to 90% transfer efficiency, reducing powder waste, while SmartClean technology ensures consistent operation and minimal downtime[1].

3. Can Ramseier Koatings customize spray gun units for specific client requirements?

Yes. Ramseier Koatings specializes in OEM manufacturing, customizing spray gun units and complete electrostatic coating systems for foreign brands, wholesalers, and manufacturers, helping them maintain unique market positions[2][5].

4. What technologies does Ramseier Koatings incorporate in their spray gun systems?

Key technologies include TCC (Total Charge Control), SmartClean cleaning systems, advanced electronic control units (SCU-S600 Mk2), and closed-loop powder management solutions for rapid color change and minimal waste[1][2][3].

5. How does Ramseier Koatings support clients after OEM manufacturing?

Ramseier Koatings provides technical consultation, after-sales support, maintenance services, and continuous innovations to ensure their clients' spray gun systems sustain peak performance and reliability[2].

[1] http://www.koatings.com/product_detail.php?rid=51&id=21

[2] https://www.yutung.com.cn/about.php?rid=33

[3] https://www.ramseierkoatings.com/electrostatic-spray-gun-and-control-system.html

[4] https://www.chyxx.com/top/201705/526349.html

[5] https://www.ramseierkoatings.com

[6] https://www.sames.com/usa/en/product-xcite-airmix-manual-spray-gun.html

[7] https://sprayequipment.com

[8] https://www.finishsystems.com/collections/automatic

[9] https://www.spraygunsdirect.co.uk

[10] https://uniram.com/spray-gun-cleaners/

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.