Content Menu

● Introduction to Powder Coating and Electrostatic Spray Guns

● How Electrostatic Spray Guns Work

>> The Fundamental Principle of Electrostatic Charging

>> Components of Automatic Electrostatic Spray Guns

● Key Factors Enhancing Powder Coating Uniformity with Automatic Electrostatic Spray Guns

>> Optimized Charge-to-Mass Ratio

>> Stable and Controlled Powder Flow

>> Advanced Nozzle Design and Maintenance

>> Electrostatic Field Shaping for Complex Geometries

>> Precise Distance and Movement Control

>> Automation and Repeatability

● Benefits of Using Automatic Electrostatic Spray Guns in Powder Coating

● Practical Steps for Optimizing Uniformity Using Automatic Electrostatic Spray Guns

>> Calibration of Coating Parameters

>> Regular Maintenance and Inspection

>> Test Sprays and Thickness Verification

>> Training and Monitoring

● Challenges and Future Directions

● Related Questions and Answers

Introduction to Powder Coating and Electrostatic Spray Guns

Powder coating is widely recognized as a superior surface finishing technique used in various industries to provide a durable, high-quality coating to metal and other substrates. It involves the application of a dry powder material that is cured under heat, resulting in a hard, uniform coating that protects and beautifies the underlying material. One of the major advancements in powder coating technology is the use of automatic electrostatic spray guns, which greatly enhance the uniformity and efficiency of the coating process.

Automatic electrostatic spray guns apply a static electric charge to powder particles, which are then attracted to the grounded workpiece, achieving an even distribution of powder particles across surfaces. This method improves coating quality, reduces waste, and ensures consistent coverage, especially on complex shapes or recessed areas. This article explores how automatic electrostatic spray guns achieve these benefits, the technical mechanisms behind their operation, and best practices for optimizing coating uniformity.

How Electrostatic Spray Guns Work

The Fundamental Principle of Electrostatic Charging

Electrostatic spray guns operate by imparting a high-voltage electric charge to powder particles as they exit the spray nozzle. The charged powder particles are drawn to the grounded part that needs coating due to the electrical attraction between the opposite charges. This electrostatic force guides the particles toward the workpiece, ensuring good adhesion and minimizing overspray.

Components of Automatic Electrostatic Spray Guns

- High Voltage Power Supply: Provides the necessary voltage (typically up to 100 kV) to charge the powder.

- Spray Nozzle: The conduit through which the charged powder particles are propelled.

- Vibration or Fluidizing Unit: Ensures the powder remains loose and flows smoothly from the spray gun.

- Control Systems: Automated controls adjust spraying parameters such as voltage, powder flow rate, and air pressure.

Automatic electrostatic spray guns integrate these components to provide a continuous and precise powder application, automating what was traditionally a manual process.

Key Factors Enhancing Powder Coating Uniformity with Automatic Electrostatic Spray Guns

Optimized Charge-to-Mass Ratio

The uniformity of powder coating is heavily influenced by how evenly the powder particles are charged. Automatic electrostatic guns maintain a controlled charge-to-mass ratio that ensures particles evenly distribute across varied surface geometries. Overcharging or undercharging can cause uneven coating thickness or powder buildup.

Stable and Controlled Powder Flow

The automatic guns use vibration technology or precisely controlled pneumatic pressure to fluidize the powder, creating a stable, homogeneous cloud of charged particles. This consistent powder delivery helps avoid clumps and ensures that the powder is directed efficiently toward the surface.

Advanced Nozzle Design and Maintenance

Nozzle shape and condition directly affect powder spray patterns. Automatic systems maintain consistent nozzle performance through controlled wear and regular calibration, resulting in a steady, uniform spray that adapts to different powder types and workpiece shapes.

Electrostatic Field Shaping for Complex Geometries

Advanced automatic guns incorporate electric field shaping elements that guide the charged particles into hard-to-reach areas like recessed surfaces or intricate contours. This technique counters the "Faraday cage" effect, where static fields can prevent powder deposition inside recesses, thereby improving coverage uniformity on complex parts.

Precise Distance and Movement Control

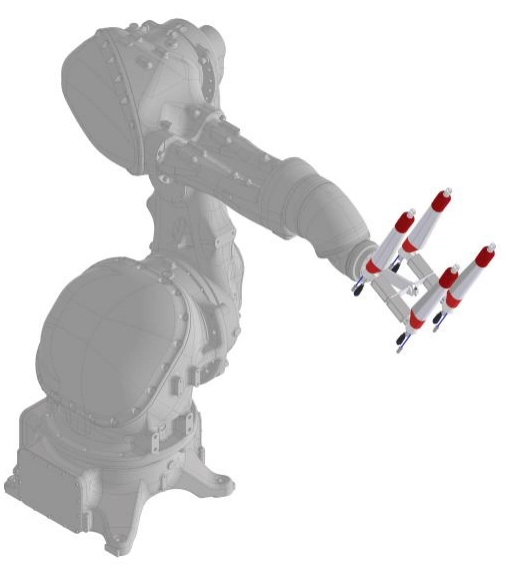

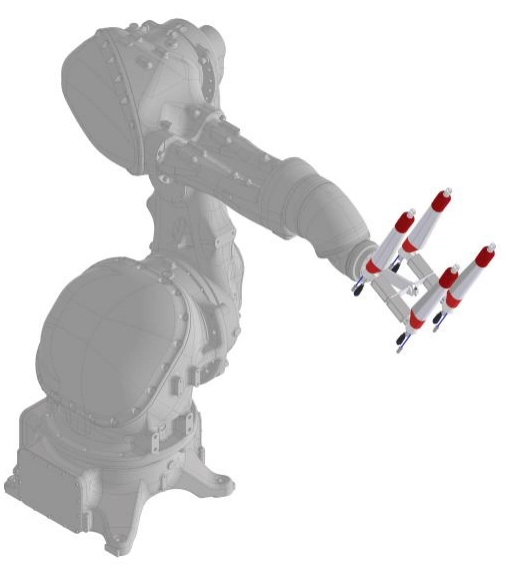

Automatic spray systems control the distance between the gun and the workpiece with robotic precision. Variations in distance can lead to powder density fluctuation. Maintaining a steady optimal distance ensures the powder particles deposit evenly without buildup or thinning spots.

Automation and Repeatability

By automating the motion and parameters of the spray gun, systems eliminate human-related variability. Robots or automated conveyors position the parts and move the gun precisely for every cycle, producing repeatable, uniform coatings suitable for high-volume production.

Benefits of Using Automatic Electrostatic Spray Guns in Powder Coating

- Increased Efficiency: Automation speeds up the coating process and supports continuous production, reducing labor costs.

- Improved Quality: The electrostatic effect pulls powder evenly onto the surface, reducing defects such as uneven thickness or bare spots.

- Powder Savings: Precision application reduces overspray and waste, leading to significant material cost savings.

- Enhanced Environmental Safety: Powder coatings emit no solvents, and reduced waste means less environmental impact.

- Better Coverage of Complex Parts: Advanced electrostatic shaping and robotic control ensure thorough coating even on complex shapes.

Practical Steps for Optimizing Uniformity Using Automatic Electrostatic Spray Guns

Calibration of Coating Parameters

Adjusting spray pressure, charge voltage, powder flow rate, and gun-to-part distance is crucial. Regular calibration ensures each parameter is optimized for the specific powder type and workpiece geometry.

Regular Maintenance and Inspection

Maintaining nozzle cleanliness and integrity prevents clogging and uneven spray patterns. Routine equipment checks ensure consistent gun performance.

Test Sprays and Thickness Verification

Conducting test coatings and measuring thickness with specialized instruments help verify uniformity and make fine adjustments as needed.

Training and Monitoring

Even with automation, skilled technicians must oversee processes and intervene if deviations occur to maintain quality.

Challenges and Future Directions

While automatic electrostatic spray guns significantly enhance coating uniformity, challenges such as coating highly irregular or deeply recessed parts remain. Innovations in electric field shaping, multi-axis robotic arms, and real-time process monitoring are being developed to push the boundaries further.

Related Questions and Answers

1. How does electrostatic charge improve powder adhesion?

Charged powder particles are attracted to the grounded workpiece, creating a strong electrostatic bond that ensures even and durable deposition.

2. Can automatic electrostatic spray guns coat non-metal surfaces?

While primarily used on conductive surfaces, pre-treatments and conductive coatings can enable application on some non-metal substrates.

3. What causes the Faraday cage effect in powder coating?

Recessed features can create an electrostatic shielding effect that prevents charged powder from entering recesses, resulting in uneven coating depth.

4. How often should electrostatic spray guns be calibrated?

Calibration frequency depends on usage but typically occurs during regular maintenance cycles to sustain consistent coating quality.

5. What are the energy benefits of using automatic electrostatic spray guns?

They use less powder and energy by targeting powder precisely, reducing overspray and lowering overall consumption.

[1] https://www.powderspraymachine.com/tune-the-powder-spray-gun-for-stable-coating-thickness/

[2] https://patents.google.com/patent/WO2016015600A1/ja

[3] https://ai.otson.com/automatic-powder-coating-lines-a-comprehensive-guide/

[4] https://www.youtube.com/watch?v=66GBenWs0c4

[5] https://aohaicoasting.en.made-in-china.com/product/gxorVMSEgsYl/China-Electrostatic-Automatic-Powder-Coating-Spray-Gun-for-Powder-Paint-Machine-Use.html

[6] https://patents.google.com/patent/CN101184555B/zh

[7] https://www.sciencedirect.com/science/article/abs/pii/S0304388698000497

[8] https://patents.google.com/patent/CN104028429A/zh

[9] https://binks.com/powder-coating-equipment/

[10] https://patents.google.com/patent/CN107398413A/zh

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.