Content Menu

● Understanding Powder Coating

>> What is Powder Coating?

>> Common Challenges in Powder Coating

● What Are Reciprocators?

>> Definition and Basic Functionality

>> Types of Reciprocators

● How Reciprocators Enhance Consistency

>> Uniformity of Coating Application

>> Accurate Speed and Stroke Control

>> Reduced Operator Fatigue and Variability

● How Reciprocators Improve Finish Quality

>> Elimination of Overspray and Waste

>> Enhanced Edge Coverage and Penetration

>> Improved Coating Thickness Control

● Operational Advantages of Using Reciprocators

>> Increased Production Efficiency

>> Flexibility in Handling Different Part Sizes and Geometries

>> Integration with Automated Systems

● Practical Considerations When Using Reciprocators

>> Proper Setup and Calibration

>> Maintenance and Troubleshooting

>> Training and Operator Skills

● Case Studies of Reciprocator Benefits in Industry

>> Automotive Component Coating

>> Appliance Manufacturing

>> Industrial Equipment Parts

● Conclusions

● Frequently Asked Questions (FAQs)

Powder coating is a widely used finishing process that offers a durable, high-quality, and environmentally friendly protective layer to metals and other materials. One of the critical factors that influence the quality of the powder coating finish is the method of application. Among various equipment and techniques, reciprocators have emerged as a vital tool in enhancing consistency and finish quality in powder coating. This article explores the reasons why reciprocators improve these aspects, detailing their functions, benefits, applications, and operational considerations.

Understanding Powder Coating

What is Powder Coating?

Powder coating is a dry finishing process that involves applying a free-flowing, dry powder made typically of thermoplastic or thermoset polymers to a substrate. The powder adheres to the surface, usually by electrostatic charge, and is then fused into a smooth, hard finish through curing in an oven. The result is a protective, attractive, and uniform coating that is thicker and more durable than conventional liquid painting.

Common Challenges in Powder Coating

Despite its myriad advantages, powder coating faces challenges related to application consistency and finish quality. Problems can include uneven thickness, streaks, orange peel texture, and poor adhesion, often caused by irregular powder distribution, improper curing, or equipment limitations.

What Are Reciprocators?

Definition and Basic Functionality

Reciprocators in powder coating are automated devices designed to move spray guns or nozzles back and forth along a fixed path, usually horizontally across the surface being coated. This controlled, repetitive linear motion ensures uniform coverage of the powder over large or complex surfaces.

Types of Reciprocators

There are various designs of reciprocators, including pneumatic, electric motor-driven, and hydraulic systems. They can be standalone units or integrated into larger powder coating booths and production lines. Some reciprocators allow adjustable speeds and stroke lengths to accommodate different part sizes and coating requirements.

How Reciprocators Enhance Consistency

Uniformity of Coating Application

One of the primary reasons reciprocators improve consistency is their ability to maintain a uniform spray pattern and distance from the part. Human operators can struggle to achieve perfect repeatability in manual spraying, especially over large or irregularly shaped items. Reciprocators automate this motion, reducing human error.

Accurate Speed and Stroke Control

Reciprocators provide precise control over the speed at which the spray gun moves and the length of each stroke. These parameters are crucial because moving too fast or too slow can result in uneven powder build-up, causing defects or wasted materials. Consistent strokes ensure the same amount of powder is deposited across the entire surface.

Reduced Operator Fatigue and Variability

Manual powder coating application requires repetitive movement, which can lead to operator fatigue and inconsistent coverage over time. Reciprocators take over this repetitive task, preventing variability due to tiredness or inattention. This leads to more reproducible results throughout production runs.

How Reciprocators Improve Finish Quality

Elimination of Overspray and Waste

Reciprocators optimize the gun movement pattern, ensuring precise application so that overspray is minimized. Overspray not only wastes powder but also compromises surface finish by generating uneven thickness. Controlling reciprocator motion reduces wasted powder and promotes a smooth, even coating.

Enhanced Edge Coverage and Penetration

Complex parts with edges, corners, and recesses can be challenging to coat evenly. Reciprocators' controlled back-and-forth motion can be programmed to focus on such features, ensuring consistent powder penetration and adhesion, which translates into a flawless finish without thin spots or bare patches.

Improved Coating Thickness Control

Thicker coatings are not always better; inconsistencies in thickness are a major defect risk. Reciprocators enable repeatable movements that build up the powder coating in a controlled manner, allowing better thickness uniformity. The resulting finish meets strict quality standards without excessive curing stress or cracking.

Operational Advantages of Using Reciprocators

Increased Production Efficiency

By automating the gun movement, reciprocators speed up the coating process and allow operators to multitask or attend to other workflow aspects. Faster, more consistent applications reduce rework and rejection rates, which increases overall throughput without sacrificing quality.

Flexibility in Handling Different Part Sizes and Geometries

Modern reciprocators can be adjusted for various stroke lengths and speeds. This makes them versatile enough to coat everything from small brackets to large panels with complex profiles, all while maintaining consistent quality standards. Users can quickly adapt the reciprocator settings to optimize for each job.

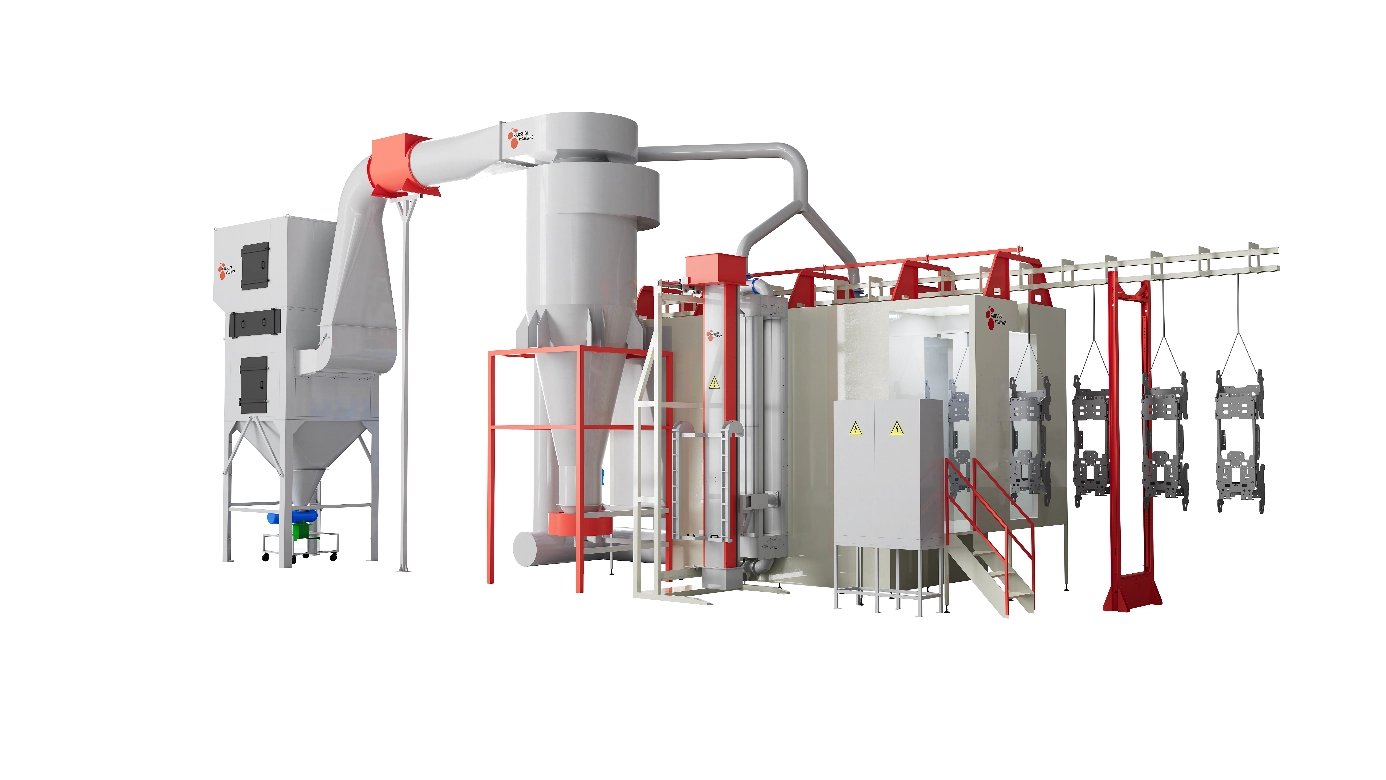

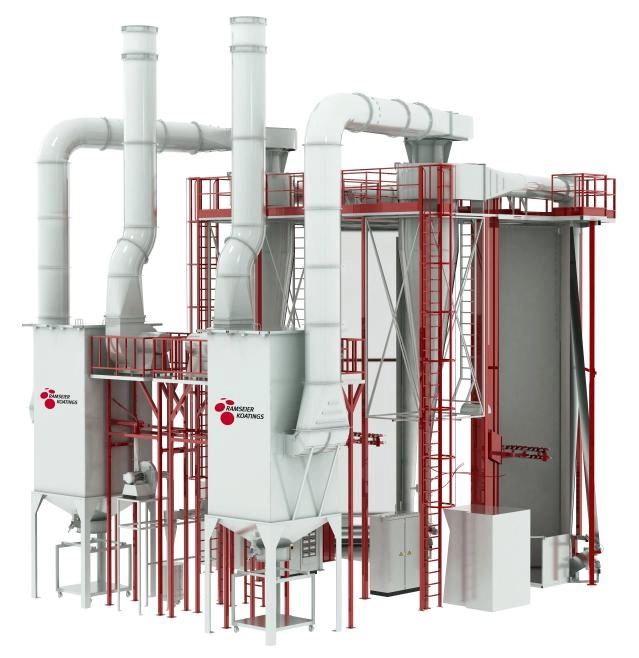

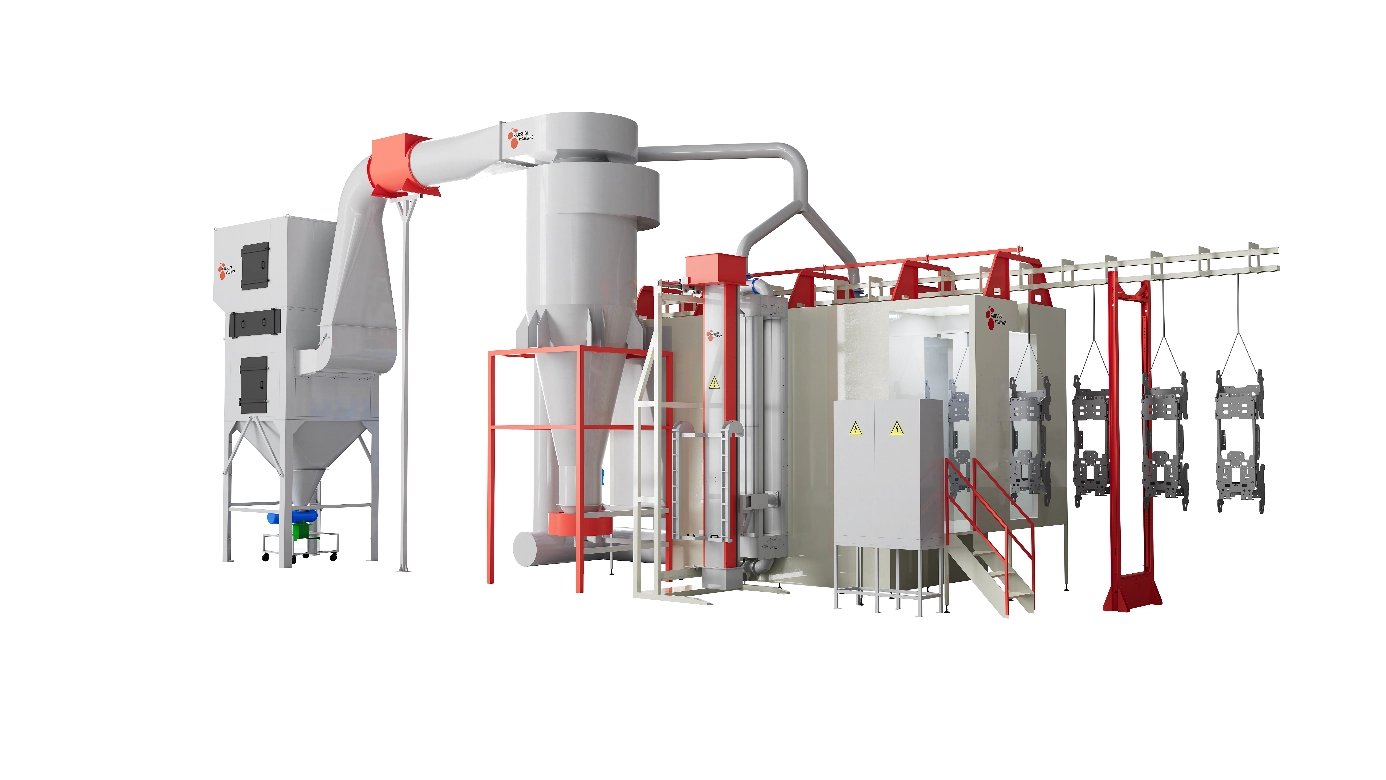

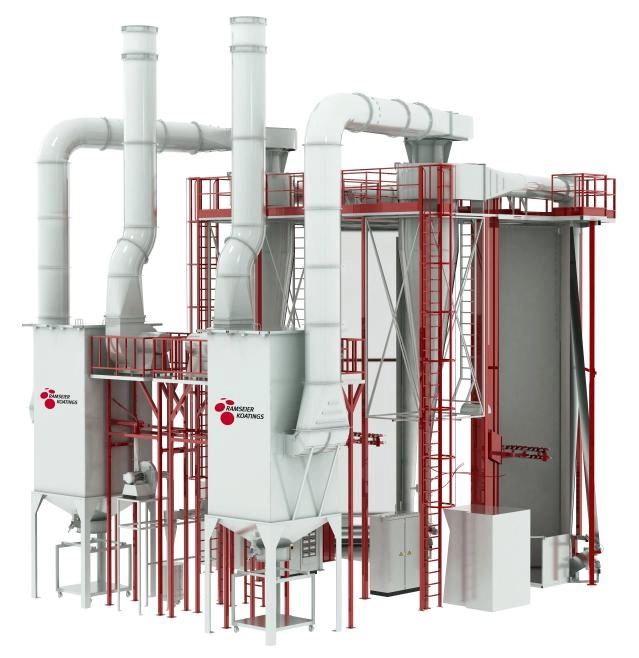

Integration with Automated Systems

Reciprocators can be integrated into fully automated coating lines with conveyors, robotic powder guns, and curing ovens. This level of automation enables high-volume, repeatable manufacturing processes suitable for industries like automotive, aerospace, and appliances, where finish quality is paramount.

Practical Considerations When Using Reciprocators

Proper Setup and Calibration

To reap the benefits of reciprocators, it is critical to properly set up and calibrate the device. Parameters like stroke length, travel speed, gun distance, and powder flow rate must be adjusted according to part size, powder type, and desired finish. Miscalibration can reduce the advantages and potentially cause defects.

Maintenance and Troubleshooting

Regular maintenance of reciprocators ensures long-term performance and minimizes downtime. Components such as belts, pulleys, motors, and guide rails should be inspected and serviced routinely. Awareness of common issues like stroke irregularities and motor malfunctions helps in timely troubleshooting.

Training and Operator Skills

Although reciprocators automate spraying motion, skilled operators are still essential to oversee the process, make adjustments, and ensure quality. Training operators on machine programming and maintenance strengthens coating consistency and encourages best practices.

Case Studies of Reciprocator Benefits in Industry

Automotive Component Coating

In automotive manufacturing, large body panels require uniform coatings for corrosion resistance and aesthetics. Reciprocators have been implemented to coat door panels, hoods, and bumpers, resulting in highly consistent finishes with minimal overspray, enhancing durability and appearance.

Appliance Manufacturing

Appliance manufacturers benefit from reciprocators when coating metal casings and parts that require smooth, visually appealing finishes. The repeatability of reciprocators reduces waste and downtime in high-mix, low-volume production runs by maintaining stable process parameters.

Industrial Equipment Parts

For heavy machinery and industrial equipment, protective powder coatings are essential. Reciprocators enable the coating of complex shapes and large items with consistent paint thickness and adhesion, improving corrosion resistance and extending equipment life.

Conclusions

Reciprocators have revolutionized the powder coating process by offering a reliable, repeatable method to apply powder evenly across diverse surfaces. Their ability to improve consistency results in reduced defects and material waste, while the enhanced finish quality meets stringent industry standards. By automating the reciprocating motion of spray guns, manufacturers gain operational efficiencies, better control over coating parameters, and the flexibility to handle parts of various sizes and complexities.

Choosing the right reciprocator system and ensuring its proper setup and maintenance is critical to realizing these benefits. With continuous advancements in automation and control technologies, reciprocators will remain a key component of powder coating lines, driving quality and productivity improvements.

Frequently Asked Questions (FAQs)

Q1: What types of parts benefit most from using reciprocators in powder coating?

A1: Parts with large flat areas, complex shapes, or multiple edges benefit significantly because reciprocators ensure uniform coverage and consistent finish quality in challenging geometries.

Q2: Can reciprocators be used with both manual and automatic powder guns?

A2: Yes, reciprocators are compatible with both types of guns. They automate the motion, regardless of whether the powder is manually or robotically fed.

Q3: How does stroke speed affect powder coating quality when using reciprocators?

A3: Stroke speed influences powder buildup; too fast may result in thin coverage, while too slow can cause thick, uneven layers. Controlled, consistent speed is key to a quality finish.

Q4: Are reciprocators suitable for small production runs or only large-scale operations?

A4: Reciprocators improve consistency in both small and large runs. Their adjustable settings make them flexible across different production volumes.

Q5: What maintenance is necessary for reciprocators to ensure long-term performance?

A5: Regular inspection of mechanical parts, lubrication of moving components, checking alignment, and timely replacement of worn parts are essential for optimal functioning.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.