Content Menu

● Understanding Automated Coating Lines

>> What Are The Components of an Automated Coating Line?

>> Industries That Benefit From Automated Coating Lines

● Reasons Why Manufacturers Are Adopting Automated Coating Lines

>> Increased Production Efficiency

>> Enhanced Quality and Consistency

>> Reduction in Labor Costs and Human Error

>> Improved Safety and Environmental Compliance

● Technical Advantages of Automated Coating Lines

>> Integration With Industry 4.0 Technologies

>> Flexibility and Customization

>> Consistent Energy Efficiency

● Challenges and Considerations

>> Initial Investment and Implementation

>> Maintenance and Technical Expertise

>> Compatibility with Specific Coating Materials

● Future Trends in Automated Coating Technology

>> Advancements in Robotics and AI

>> Sustainability Focus

>> Greater Integration with Supply Chain

● Frequently Asked Questions

In the dynamic world of manufacturing, staying competitive requires constant innovation and efficiency improvement. One significant advancement that many top manufacturers are adopting is the implementation of automated coating lines. These systems offer enhanced precision, faster production rates, and improved product quality compared to traditional manual or semi-automated coating processes. This article explores why leading manufacturers are making the switch to automated coating lines, examining the benefits, challenges, and future trends of this technology.

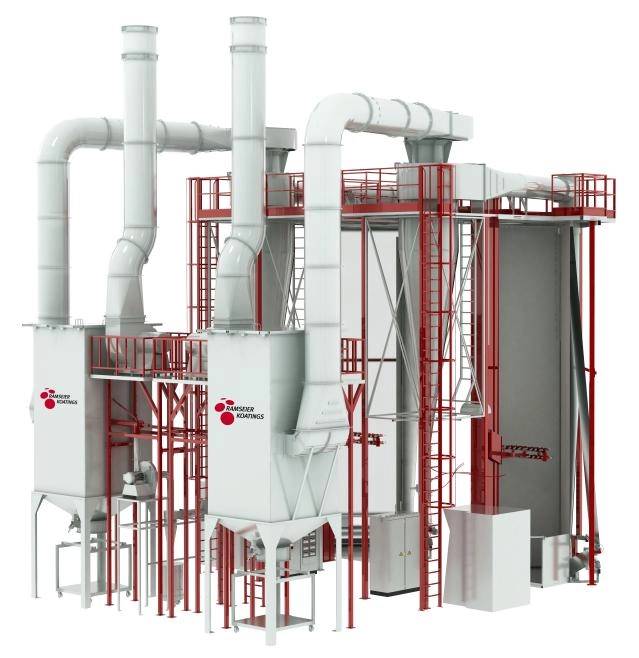

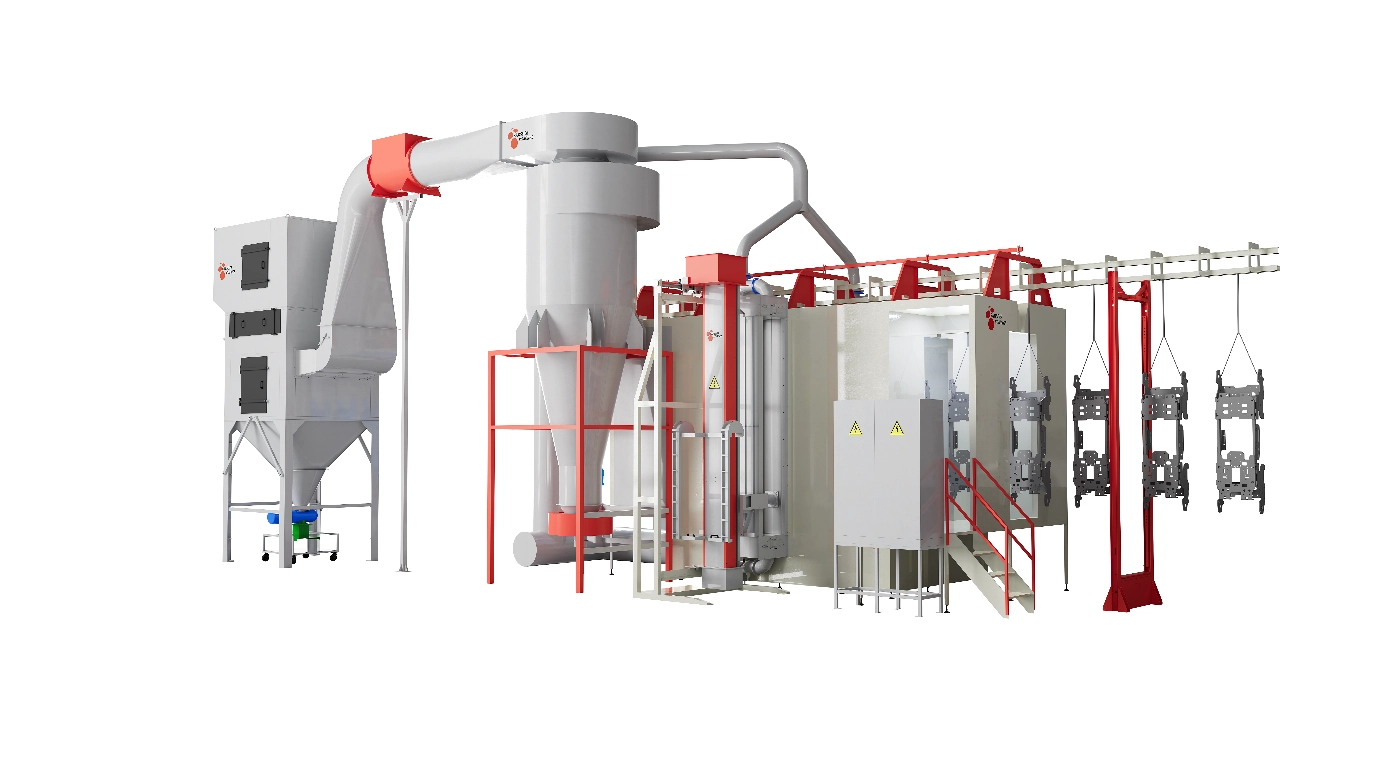

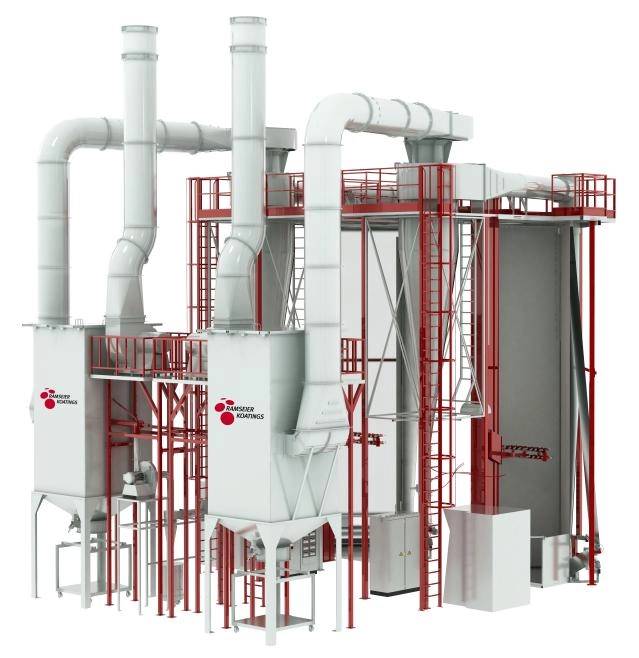

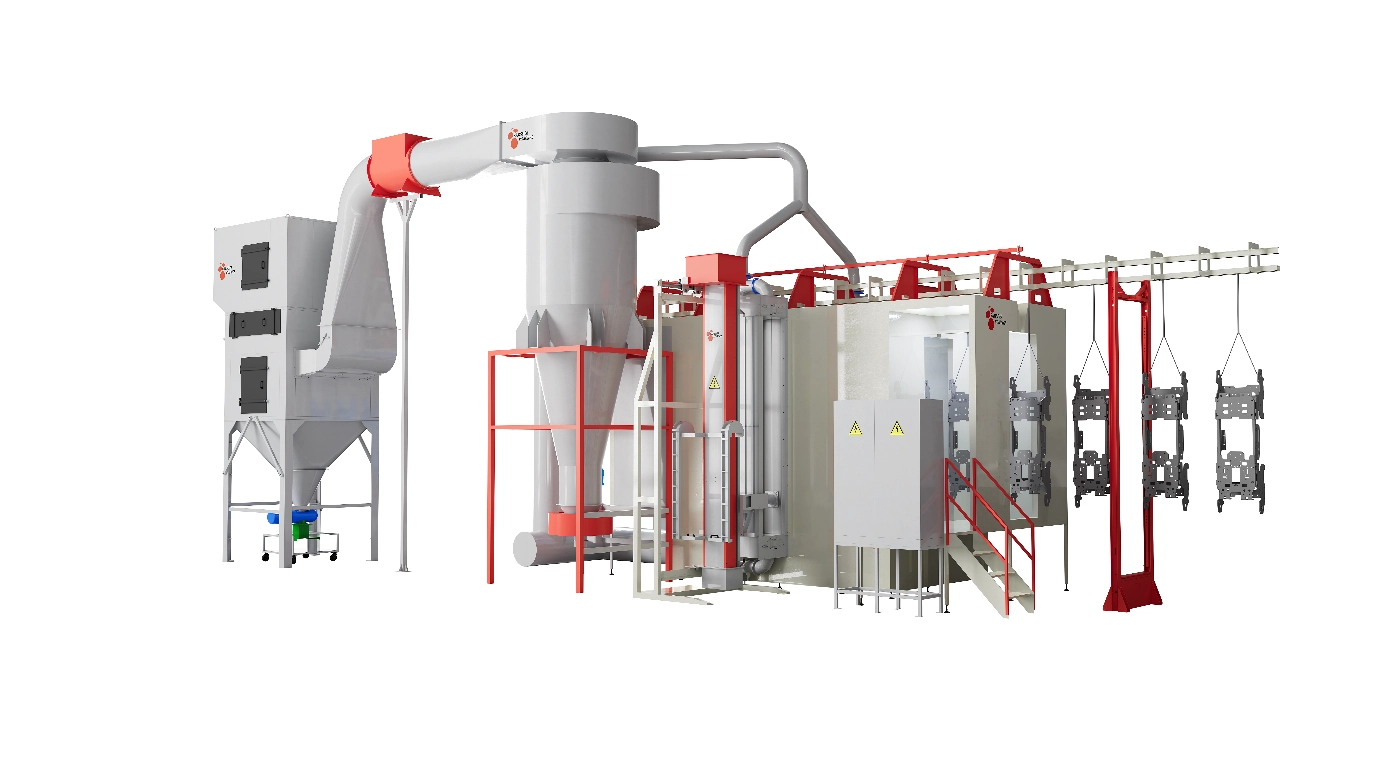

Understanding Automated Coating Lines

Automated coating lines involve integrating robotics, conveyor systems, and advanced control software to apply protective or decorative coatings on various products. These coatings can include paints, varnishes, lacquers, powders, or other materials depending on the industry and product requirements.

What Are The Components of an Automated Coating Line?

An automated coating line typically includes several key components working together seamlessly:

- Conveyor System: Moves products through different stages of the coating process.

- Coating Application Equipment: Could be robotic arms, spray guns, or dip tanks that precisely apply coating materials.

- Drying and Curing Chambers: Ensure coatings harden correctly using heat, UV light, or other methods.

- Quality Inspection Systems: Use sensors and cameras to check coating thickness and uniformity.

- Control Software: Coordinates all operations and provides real-time monitoring.

Industries That Benefit From Automated Coating Lines

Many industries see major advantages from automated coatings, including:

- Automotive parts manufacturing

- Electronics and appliance production

- Furniture and woodworking

- Aerospace components

- Packaging and metal fabrication

These sectors require high-quality finishes that enhance durability, functionality, and aesthetic appeal.

Reasons Why Manufacturers Are Adopting Automated Coating Lines

Increased Production Efficiency

Automated coating lines significantly speed up the production process by consistently applying coatings without breaks or fatigue common in manual labor. This increased throughput helps manufacturers meet growing demand while reducing lead times.

Manufacturers can run coating operations continuously with minimal downtime. Automated systems can also simultaneously handle multiple products or stages, improving overall line productivity.

Enhanced Quality and Consistency

Manual coating can result in variable thickness, uneven coverage, and defects due to human error. Automated lines precisely control application parameters such as spray pattern, flow rate, and drying conditions.

This precision ensures uniform coating thickness and high-quality finishes. The use of integrated inspection systems further guarantees product compliance with stringent quality standards, reducing rework and waste.

Reduction in Labor Costs and Human Error

Automating the coating process minimizes reliance on manual labor, which can be costly and inconsistent in skill levels. Manufacturers can redeploy personnel to more strategic roles while reducing labor-related risks such as injury or error-induced defects.

Lower labor costs combined with enhanced consistency make automated lines economically attractive for high-volume production.

Improved Safety and Environmental Compliance

Coating processes often involve hazardous chemicals or volatile organic compounds (VOCs). Automated systems can be designed with enclosed application and ventilation to reduce worker exposure and environmental impact.

The precision application also minimizes material waste, lowering emissions and disposal requirements. These factors help manufacturers meet increasingly strict workplace safety and environmental regulations.

Technical Advantages of Automated Coating Lines

Integration With Industry 4.0 Technologies

Modern automated coating lines integrate with the Internet of Things (IoT), advanced sensors, and data analytics. This connectivity enables predictive maintenance, real-time process optimization, and digital traceability of coating quality.

Manufacturers benefit from reduced downtime and better decision-making, driving continuous improvement.

Flexibility and Customization

Contrary to perceptions about rigid automation, many coating lines are highly flexible. Programmable robots and modular equipment allow easy reconfiguration for different product sizes, shapes, or coating types.

This flexibility supports diverse production needs such as small batch customizations or rapid product changeovers.

Consistent Energy Efficiency

Automated equipment often uses energy more efficiently than manual setups by optimizing coating cycles and drying methods. Smart controls reduce energy consumption during idle times or less intensive operations.

The improved energy profile lowers operational costs and supports sustainability goals.

Challenges and Considerations

Initial Investment and Implementation

Automated coating lines require significant capital investment and careful planning. Manufacturers must analyze ROI based on expected throughput gains, labor savings, and quality improvements.

Implementation also involves employee training, integrating with existing processes, and addressing potential downtime during transition.

Maintenance and Technical Expertise

Maintaining automated systems demands experienced maintenance teams and access to spare parts. Manufacturers may need to upskill workers or contract specialized service providers to ensure reliable operation.

Compatibility with Specific Coating Materials

Certain coatings or substrates may pose challenges for automation, such as highly viscous materials or delicate surfaces. Manufacturers must evaluate material compatibility and possibly adjust formulations or application methods.

Future Trends in Automated Coating Technology

Advancements in Robotics and AI

The next generation of automated coating lines will increasingly use artificial intelligence for adaptive spraying, defect prediction, and autonomous adjustments. Robotics with enhanced dexterity will handle complex geometries more efficiently.

Sustainability Focus

There is growing emphasis on environmentally friendly coatings, solvent-free processes, and closed-loop systems to recycle overspray. Automated lines will evolve to support these green initiatives.

Greater Integration with Supply Chain

Future lines are expected to be part of fully digital production networks, communicating with upstream and downstream systems for holistic manufacturing optimization from raw material input to final packaging.

Frequently Asked Questions

Q1: What types of coatings can automated coating lines handle?

Automated coating lines can apply a wide range of coatings including paints, powders, varnishes, and lacquers on materials such as metal, plastic, wood, and composites.

Q2: Are automated coating lines suitable for small manufacturers?

While the upfront costs may be higher, smaller manufacturers with high-quality or volume demands may benefit due to improved efficiency and reduced labor. Customized smaller-scale systems are also available.

Q3: How do automated coating lines improve product quality?

By precisely controlling application parameters and integrating inspection systems, these lines deliver uniform coating thickness, reduce defects, and ensure consistent surface finishes.

Q4: What is the typical ROI period for automated coating line investments?

Return on investment varies based on production scale and complexity but is often realized within 2 to 5 years due to labor savings, increased throughput, and reduced material waste.

Q5: How do automated coating lines contribute to environmental sustainability?

They reduce material waste and VOC emissions through precise application and can include closed systems that limit environmental exposure to hazardous chemicals.

Hot Tags: China, Global, OEM, private label, manufacturers, factory, suppliers, manufacturing company

.

.